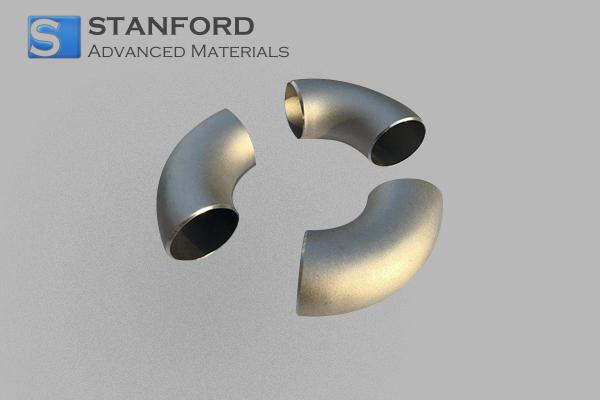

TM0150 Titanium Fitting (Ti Fitting)

| Catalog No. | TM0150 |

| Size | 1/2" to 24" NPS |

| Density | 4.51 g/cc |

| Material | C.P. Titanium & Titanium Alloy |

| Standard | AMSE B16.9 |

| MSDS/SDS |

With a wide range of fittings, flanges, and forgings, Stanford Advanced Materials (SAM) offers diverse Titanium Fittings that are used in various industries. These components are precision-made from high-quality titanium alloy materials, ensuring exceptional corrosion resistance, high strength, and lightweight. These Titanium fitting components are suitable for use in demanding applications.

Related products: Ta Foil / Ta Strip, Ta Tube / Ta Pipe, Ta Wire, Ta Sheet / Ta Plate, Tantalum Tungsten Alloy, Tantalum Niobium Alloy and Tantalum Compounds

Titanium Fitting (Ti Fitting) Description

Titanium Fitting is a high-performance fitting made of titanium alloy, which is widely used in aerospace, automobile, petroleum, chemical, and other industries. It has the characteristics of corrosion resistance, high strength, lightweight, and good biocompatibility. Titanium Fitting can replace steel fittings on many occasions to reduce the weight and improve the corrosion resistance of the structure. In addition, titanium fittings also have good fatigue resistance and creep resistance, which can effectively improve the service life of the structure. Titanium Fitting is an excellent choice for high-performance and corrosion-resistant piping and tubing applications.

Specifications of Titanium Elbow

Size: NPS 1/4"-24"; 45°, 90°, 180°, or according to per customer's drawings and specifications

Material: Gr.1, Gr.2, Gr.7, Gr.9, Gr.12

Standard: ASTM, DIN

Specifications of Titanium Tee

Size: NPS 1/2"-48", WT: SCH5S-SCH160

Material: Gr.1, Gr.2, Gr.7, Gr.9, Gr.12

Standard: ASME B16.9, ASTM B363, DIN

Specifications of Titanium Stub End

Size: NPS1/2"-24", WT: SCH5S-SCH160S

Material: Gr.1, Gr.2, Gr.7, Gr.9, Gr.12

Standard: ASME B16.9, ASTM B363, DIN.

Titanium Fitting Applications

1. Aerospace Industry: Titanium Fittings are widely used in the aerospace industry due to their high strength, corrosion resistance, and lightweight. They are used in airframes, engines, and other critical components to ensure durability and reliability in flight operations.

2. Automotive Industry: Titanium Fittings are employed in the automotive industry to improve corrosion resistance and reduce the weight of vehicles. They are used in fuel systems, exhaust systems, and other critical parts that require high strength and durability.

3. Petroleum and Chemical Industry: Titanium Fittings have excellent corrosion resistance and can withstand harsh environments in the petroleum and chemical industries. They are used to connect pipes, valves, and other equipment in chemical reactors, oil refineries, and other processes.

4. Medical Industry: Titanium Fittings are biocompatible and can be used in medical applications such as orthopedic implants, surgical instruments, and medical devices that require long-term use in the human body. They provide a durable and reliable connection solution for these devices.

Titanium Fitting Packaging

Our Ti fittings are tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

FAQs

1 Can Tantalum Capillary Tubes be customized?

Yes, Tantalum Capillary Tubes can be customized to fit specific size, thickness, and length requirements. Customization options are available for different diameters, wall thicknesses, and lengths depending on the needs of the application.

2 How are Tantalum Capillary Tubes manufactured?

Tantalum Capillary Tubes are typically produced through a process called drawing, where a thicker piece of tantalum is drawn through a die to create a thin-walled tube. The process ensures that the tubes have the desired dimensions and uniformity in thickness and length.

3 How can I buy Tantalum Capillary Tubes?

Tantalum Capillary Tubes can be purchased from specialized metal suppliers or manufacturers that offer the product in various grades, sizes, and custom specifications. Requesting a quote based on your specific needs (e.g., length, diameter, or purity) is recommended for the most accurate pricing and availability.

Related articles:

CP Titanium – Commercially Pure Titanium (1)

CP Titanium – Commercially Pure Titanium (2)

Titanium Used in the Aerospace Industry

Medical Grade Titanium Materials - Indispensable to the Medical Industry

Application of Titanium in Watch

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!