Lithium Compounds in the Semiconductor Industry

Introduction

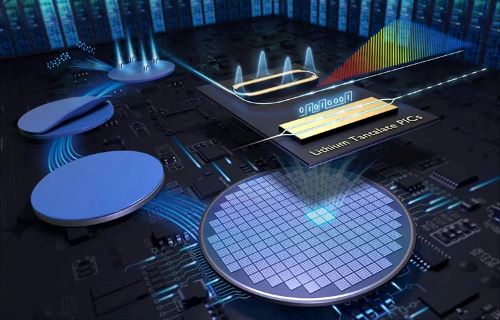

Lithium compounds have become increasingly important in the semiconductor industry due to their unique physical, chemical, and electrical properties. These materials, particularly lithium niobate (LiNbO₃) and lithium tantalate (LiTaO₃), play critical roles in optoelectronics, telecommunications, and various advanced semiconductor devices. Let’s explore the key lithium compounds used in semiconductors, their properties, and their applications.

[1]

[1]

1. Lithium Niobate (LiNbO₃)

Lithium niobate is one of the most prominent lithium-based materials used in semiconductor applications, often referred to as the "optical silicon" of the photonics era. This material is highly valued for its electro-optic, piezoelectric, and nonlinear optical properties, making it an indispensable material in optical and telecommunications technologies.

Key features of LiNbO₃ include:

- Electro-Optic Effect: Lithium niobate’s ability to change its refractive index in response to an applied electric field makes it an essential material in electro-optic modulators. These modulators are crucial for encoding data onto light signals in fiber optic communication systems.

- Piezoelectric Properties: Lithium niobate is used in surface acoustic wave (SAW) devices, which are important in mobile phones and radio frequency (RF) communication systems.

- Nonlinear Optical Properties: This material’s nonlinear optical properties allow it to perform frequency doubling in laser systems, converting light from one frequency to another.

Therefore, it is widely used in:

- Optical Modulators: Widely used in telecommunications for high-speed data transmission.

- SAW Filters: Used in wireless communication devices, including smartphones and GPS systems.

- Frequency Doubling: Used in laser technologies for applications such as microscopy and precision measurement.

2. Lithium Tantalate (LiTaO₃)

Like lithium niobate, lithium tantalate possesses excellent electro-optic and piezoelectric capabilities, allowing it to be used in similar applications.

Some of its key benefits include:

- Higher Electro-Optic Coefficient: Lithium tantalate has a larger electro-optic effect, making it more effective for modulating light in photonic devices.

- Greater Piezoelectric Response: This characteristic allows for improved performance in sensors and actuators, particularly in acoustic devices.

- Superior Thermal Stability: Lithium tantalate maintains its properties better at elevated temperatures, enhancing reliability in high-temperature applications.

- Lower Optical Losses: It typically exhibits lower absorption losses in the infrared range, which is beneficial for optical communications.

Lithium tantalate (LiTaO₃) has the following thin-film applications due to its unique properties.

- Optical Waveguides: Its high electro-optic coefficient enables efficient modulation of light, making it ideal for integrated optical circuits.

- Frequency Converters: LiTaO₃ is used in devices that convert one frequency of light to another, benefiting from its low optical losses and high non-linear coefficients.

- Surface Acoustic Wave (SAW) Devices: The material's superior piezoelectric properties make it suitable for SAW filters and sensors, commonly used in telecommunications.

- Thin-Film Capacitors: Its excellent dielectric properties allow for the fabrication of high-performance capacitors in microelectronics.

- Laser Devices: LiTaO₃ is employed in laser technologies for frequency doubling and optical parametric oscillation, leveraging its non-linear optical capabilities.

3. Lithium Fluoride (LiF)

Lithium fluoride is another lithium compound possessing thin-film applications. It is widely used as a thin-film material in optoelectronic devices, particularly as a buffer layer in organic light-emitting diodes (OLEDs) and other semiconductor applications.

Lithium fluoride has a large bandgap, making it transparent to ultraviolet (UV) light and ideal for use in UV optics. Its ability to transmit UV light makes it valuable in optoelectronics and photonics.

This thin-film material finds applications in:

- OLEDs: Used as a buffer layer to improve efficiency and performance.

- Thin-Film Optoelectronics: Applied in various optoelectronic devices, including UV detectors and sensors.

4. Lithium Disilicate (Li₂Si₂O₅)

Additionally, lithium disilicate is primarily used in glass-ceramic materials, which have potential applications in semiconductor packaging.

These materials are valued for their high mechanical strength, durability, and resistance to thermal shock. Lithium disilicate is known for its superior toughness and ability to withstand high stresses. Its resistance to thermal shock makes it useful in applications that involve rapid changes in temperature.

The semiconductor packing applications involve:

- Semiconductor Packaging: Used in the protection and insulation of semiconductor components.

- High-Strength Ceramic Applications: In advanced electronics, lithium disilicate-based glass ceramics can be used in mechanical components that require high strength and stability.

5. Lithium Sulfide (Li₂S)

Lithium compounds are also used for batteries. Lithium sulfide is an emerging material in the development of solid-state batteries.

It provides efficient and compact energy storage with the following features.

- High Ionic Conductivity: Lithium sulfide offers excellent ionic conductivity, making it a strong candidate for use in all-solid-state lithium-ion batteries.

- Compatibility with High-Energy Cathodes: Lithium sulfide can pair well with high-energy cathodes, improving the overall efficiency of battery systems.

6. Lithium Phosphates (Li₃PO₄)

Lithium phosphates are used in the development of thin-film lithium-ion batteries, which can be integrated into microelectronic devices and semiconductor systems.

Li₃PO₄ is useful for:

- Thin-Film Batteries: Used in microchips and small electronic devices that require compact and efficient power solutions.

- Wearable Devices and Sensors: Lithium phosphates enable the integration of energy storage into small semiconductor systems, powering sensors and wearable electronics.

Conclusion

Lithium compounds are critical to the advancement of modern semiconductor technologies. Lithium niobate and lithium tantalate are cornerstone materials in optoelectronics and telecommunications, known for their electro-optic and piezoelectric properties. As the demand for more efficient, scalable, and integrated semiconductor solutions grows, lithium compounds will continue to shape the future of electronics, communications, and energy storage systems.

|

Lithium Compound |

Key Features |

Applications |

|

- Strong electro-optic effect |

- Optical modulators |

|

|

- Wide transparency range |

- Optical modulators |

|

|

Lithium Fluoride (LiF) |

- Wide bandgap |

- OLEDs |

|

Lithium Disilicate (Li₂Si₂O₅) |

- High mechanical strength |

- Semiconductor packaging |

|

Lithium Sulfide (Li₂S) |

- High ionic conductivity |

- Solid-state batteries |

|

Lithium Phosphates (Li₃PO₄) |

- High energy density |

- Thin-film batteries |

For more information and products, please check Stanford Advanced Materials (SAM).

Reference:

[1] Wang, C., Li, Z., Riemensberger, J. et al. Lithium tantalate photonic integrated circuits for volume manufacturing. Nature 629, 784–790 (2024). https://doi.org/10.1038/s41586-024-07369-1