Electrode Materials for Plasma Cutting Machines

Introduction

What is plasma cutting? How does the entire process work? What parts does a plasma cutter contain? This article will answer these questions and provide you with important information about plasma cutting electrode materials.

Plasma Cutting Technology: Mechanism and Benefits

[1]

[1]

Plasma cutting is a process that employs a high-velocity jet of ionized gas, known as plasma, to cut through electrically conductive materials. The procedure involves several key steps:

1. Initiating the Arc: A high-frequency spark ionizes the gas within the plasma torch, creating a conductive channel for the electric arc.

2. Forming the Plasma: The electric arc heats the gas to an extremely high temperature, converting it into plasma. This plasma jet is then expelled through a nozzle at high speed.

3. Cutting the Material: The intense heat from the plasma jet melts the material at the cutting point, while the high-velocity gas stream blows away the molten metal, creating a precise cut.

This process offers several advantages over traditional cutting methods:

- Speed: It is significantly faster than traditional cutting methods, particularly on thinner materials.

- Precision: Provides clean and precise cuts with minimal heat-affected zones, reducing the need for secondary finishing.

- Versatility: Capable of cutting a wide range of metals, including carbon steel, stainless steel, aluminum, copper, and various alloys.

- Cost-Effective: Lower operating costs compared to other cutting methods, such as laser cutting, due to reduced consumable usage and maintenance requirements.

Plasma Cutting Machine: Components and Importance

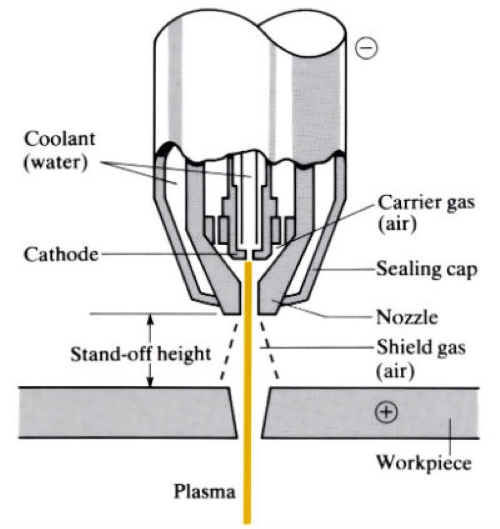

A plasma cutting machine consists of several key components. They work together to perform the cutting process. Here are the main components:

1. Power Supply:

The power supply is responsible for providing the necessary electrical power to generate the plasma arc. Its importance lies in determining the machine's capacity and cutting capabilities, which typically range from 30 to 400 amps.

2. Plasma Torch:

The plasma torch houses the electrode and nozzle through which the plasma arc is directed. It is designed to withstand high temperatures and provide precise control over the cutting process.

3. Electrode:

The electrode generates the arc that ionizes the gas to form plasma. It is a critical component affecting the stability and quality of the plasma arc, usually made of copper with a high-durability insert such as hafnium or tungsten.

4. Nozzle:

The nozzle directs the plasma jet onto the workpiece. It ensures a focused and high-velocity plasma stream, made from high-temperature resistant materials.

5. Gas Supply:

The gas supply provides the necessary gas, such as compressed air, oxygen, nitrogen, or argon, to create the plasma. The choice of gas impacts the cut quality and efficiency, and it is tailored to the material being cut.

6. Control Panel:

The control panel allows the operator to adjust settings such as current, gas flow, and cutting speed. Modern machines include digital interfaces for more precise control and ease of use.

These components work together to create a high-temperature plasma arc that melts and cuts through the workpiece material efficiently and precisely.

Electrode Materials for Plasma Cutting Machines

Electrodes are pivotal in plasma cutting machines, directly influencing the cutting performance and longevity of the equipment. Inside a plasma cutting torch, the electrode is positioned in the center, with the nozzle located just below it. These two components are considered consumable parts in plasma cutting. Consumable parts need to be replaced in a timely manner because severely worn electrodes, nozzles, and vortex rings can produce uncontrollable plasma arcs. Such arcs can easily cause serious damage to the cutting torch.

To obtain such an extended lifespan and improved performance, the primary materials used for electrodes include:

1. Copper:

- Properties: Excellent electrical conductivity and heat dissipation.

- Use: Forms the main body of the electrode, providing a base for high-durability inserts.

2. Hafnium:

- Properties: High melting point, excellent durability, and conductivity.

- Use: Often used as an insert at the electrode tip to enhance performance and lifespan.

3. Tungsten:

- Properties: High melting point and good conductivity.

- Use: Used in some electrodes for its durability under high temperatures.

Advanced Electrode Material: Hafnium Wire

Hafnium Wire:

Recent advancements in electrode materials have highlighted the benefits of using hafnium wire inserts in electrodes. Hafnium wire offers several advantages.

Hf's high melting point allows it to withstand the extreme temperatures of the plasma arc, leading to longer electrode life. This longevity translates into fewer electrode replacements and less downtime. In terms of performance, hafnium electrodes provide stable arc initiation and maintenance, resulting in cleaner cuts and reducing the need for frequent electrode changes. While hafnium electrodes may be initially more expensive, their longer lifespan and improved performance can make them more cost-effective in the long run by reducing overall operating costs.

Hafnium Wire vs Zirconium Wire:

1. Performance Differences:

Due to its material characteristics, hafnium wire used in plasma cutting nozzles can maintain good chemical stability and corrosion resistance in high-temperature plasma gas environments. Its high melting point ensures the stability of the cutting nozzle, preventing fusion and deformation. In contrast, zirconium wire is prone to oxidation and corrosion and is susceptible to thermal expansion during high-temperature cutting, leading to deformation of the cutting nozzle and making it more easily damaged.

2. Application Scenarios:

Hafnium wire is ideal for high-precision cutting and processing fields due to its high corrosion resistance, chemical stability, high melting point, and good cutting stability. It is especially suitable for cutting difficult materials. On the other hand, zirconium wire is mainly used in low-demand cutting environments, such as when cutting copper and aluminum materials, where the requirements for durability and stability are less stringent. [2]

Conclusion

Plasma cutting machines are essential tools in modern metalworking, offering unmatched speed, precision, and versatility. The choice of electrode material is critical to the performance and efficiency of these machines. Recent advancements, such as the use of hafnium wire, have significantly improved the capabilities of plasma cutting technology, ensuring cleaner cuts, longer electrode life, and overall cost savings. Understanding the importance of high-quality electrode materials and staying informed about technological advancements can help operators achieve optimal results in their cutting operations. For more information, please check Stanford Advanced Materials (SAM).

Reference:

[1]The Open University. (2018). Plasma arc cutting. The Open University. https://www.open.edu/openlearn/science-maths-technology/engineering-technology/manupedia/plasma-arc-cutting

[2] Xu, S. (2005). Zirconium-hafnium wire processing and its application in plasma cutting electrodes. Chinese Journal of Rare Metals. https://www.cqvip.com/qk/93288x/200501/15443902.html