Magnetostriction and Transformers

What Is Magnetostriction?

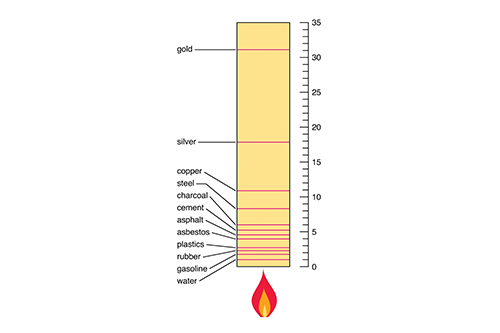

Magnetostriction is a phenomenon where ferromagnetic materials change their shape or dimensions when subjected to a magnetic field. This effect occurs due to the alignment of magnetic domains within the material, leading to mechanical strain. The degree of magnetostriction varies among different materials, with some exhibiting significant size changes while others show minimal effects.

How Magnetostriction Affects Transformers

Transformers rely on magnetic cores to transfer electrical energy between circuits. Magnetostriction in these cores can lead to several issues:

- Noise Generation: The periodic expansion and contraction of the core material can produce audible noise, commonly heard as a humming sound in transformers.

- Energy Loss: Dimensional changes can cause mechanical vibrations, leading to energy losses and reduced efficiency.

- Structural Stress: Continuous magnetostriction may result in material fatigue, potentially shortening the lifespan of the transformer.

|

Aspect |

Impact of Magnetostriction |

Mitigation Techniques |

|

Noise Generation |

Causes humming sounds due to core vibrations |

Use of damping materials |

|

Energy Loss |

Leads to reduced efficiency from mechanical strain |

Select low magnetostriction materials |

|

Structural Stress |

May result in material fatigue and reduced lifespan |

Optimize core design and geometry |

|

Performance |

Affects overall transformer reliability |

Implement advanced core treatments |

For more information, please check Stanford Advanced Materials (SAM).

Mitigation Strategies in Transformer Design

To minimize the adverse effects of magnetostriction, engineers implement various design strategies:

- Material Selection: Using materials with low magnetostriction coefficients reduces dimensional changes.

- Core Design: Optimizing the geometry of the core can alleviate stress and vibrations caused by magnetostriction.

- Damping Techniques: Incorporating damping materials absorbs mechanical vibrations, decreasing noise and energy loss.

Applications of Magnetostriction in Modern Technology

Beyond transformers, magnetostriction finds applications in several technologies:

- Sensors and Actuators: Magnetostrictive materials are used in precise movement control and sensing applications.

- Ultrasonic Devices: Leveraging magnetostriction for generating and detecting ultrasonic waves in medical and industrial equipment.

- Energy Harvesting: Converting mechanical vibrations into electrical energy using magnetostrictive materials.

Frequently Asked Questions

What is magnetostriction?

Magnetostriction is the change in shape or dimensions of ferromagnetic

materials when exposed to a magnetic field.

How does magnetostriction impact transformer efficiency?

It causes mechanical vibrations and energy losses, reducing the overall

efficiency of the transformer.

Can magnetostriction be completely eliminated in transformers?

While it cannot be entirely eliminated, its effects can be significantly

reduced through material selection and design optimization.

What materials are best to minimize magnetostriction in

transformers?

Materials with low magnetostriction coefficients, such as certain alloys of

silicon steel, are preferred to minimize dimensional changes.

Are there any benefits of magnetostriction in other technologies?

Yes, magnetostriction is utilized in sensors, actuators, ultrasonic devices,

and energy harvesting applications due to its ability to convert magnetic

energy into mechanical energy and vice versa.