Heating Furnaces for Surface Deposition Application

Introduction

Heating furnaces are vital in the surface deposition processes of Physical Vapor Deposition (PVD) and Thermal Spraying (TSP). These techniques are used to create thin films and coatings by transferring material from a source to a substrate. In PVD, methods such as evaporation, sputtering, and pulsed laser deposition rely on precise temperature control provided by heating furnaces to ensure high-quality film deposition. Similarly, in TSP, heating furnaces are crucial for heating source materials to a molten or semi-molten state, facilitating the formation of dense, uniform coatings. This article explores the critical role of heating furnaces in both PVD and TSP processes, emphasizing their importance in temperature regulation, material transfer, and coating property control.

Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) is a technique used to create thin films and coatings by physically transferring material from a source material to a substrate. PVD techniques include a variety of methods such as evaporation, sputtering, and pulsed laser deposition. A heated furnace plays a key role in the PVD process, providing the necessary temperature control to facilitate the evaporation or sputtering of the material, thus ensuring high-quality film deposition.

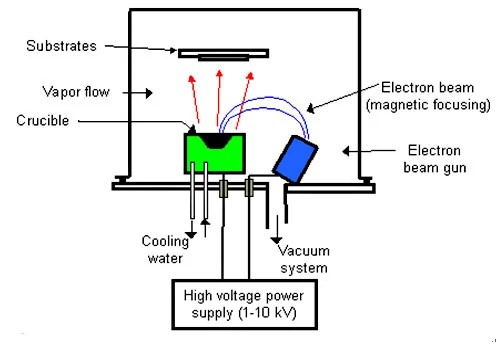

PVD is a technique that utilizes a physical process to transfer material from a source material to a substrate. The basic steps include heating the source material, causing it to evaporate or sputter to form gas phase particles, transferring the gas phase particles to the substrate surface in a vacuum or low-pressure environment and ultimately condensing the gas phase particles on the substrate surface to form a thin film.

Fig. 1 Schematic Diagram of The PVD Process

The role of the heating furnace in PVD includes:

1. Provide evaporation temperature:

Evaporation source: The heating furnace is used to heat the source material so that it reaches the evaporation temperature and produces vapor. The evaporation temperature varies from material to material, usually between 500°C and 3000°C.

Temperature control: The heating furnace requires precise temperature control to ensure a stable evaporation rate and uniform vapor flow density.

2. Facilitating the sputtering process:

Target heating: In some sputtering processes, heating ovens are used to heat the target to make it more susceptible to ion bombardment to produce gas phase particles.

Substrate heating: Substrate heating helps to improve film adhesion and crystallization quality. Typical substrate temperatures range from 100°C to 800°C, depending on the material and application requirements.

3. Control of film properties:

Film structure: Temperature has a significant effect on the crystal structure, density, and stress of the film. With precise temperature control, the structure and properties of the film can be optimized.

Stress control: Heating furnaces can be used to reduce internal stresses in the film by regulating the substrate temperature to avoid cracking and peeling.

A resistance heating furnace with resistance wire heating is often used in PVD and can be used for both the evaporation source and the substrate. It has precise temperature control and is suitable for most PVD applications. There are also electron beam heating furnaces, which utilize an electron beam to bombard the surface of the source material and heat it to the evaporation temperature. It is suitable for high melting point materials with high heating efficiency and fast temperature response. As well as induction heating furnaces, which utilize electromagnetic induction to heat the source material or substrate. It is fast and suitable for processes that require rapid warming and cooling.

Example Analysis

1. Thermal Evaporation (Thermal Evaporation): Used for the deposition of metal films, semiconductor materials, and organic materials. A furnace is used to heat the source material (e.g., gold, aluminum, silicon), causing it to evaporate and be deposited on a substrate to form a thin film. Typical temperatures range from 600°C to 1500°C. 2.

2. Electron Beam Evaporation: Electron beam evaporation is used for thin film deposition of high melting point materials such as tungsten, molybdenum, and ceramic materials. An electron beam heater is used to heat the source material, causing it to evaporate at high temperatures and be deposited on the substrate. Precise temperature control of the furnace ensures the formation of high-quality films.

3. Sputter Deposition: Sputter deposition is widely used in the manufacture of optical coatings, semiconductor devices, and hard coatings. Furnaces are used to heat the target and substrate to improve sputtering efficiency and film quality. The substrate is usually heated at temperatures between 100°C and 500°C, which helps in crystallization and adhesion of the film.

Thermal Spraying

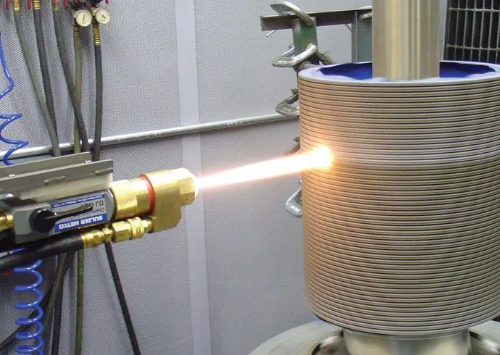

Thermal Spraying (TSP) is a technique of forming a coating by heating a source material and accelerating it to impact a substrate surface. A heated oven plays a key role in the thermal spraying process by providing the necessary thermal energy to heat the sprayed material to a molten or semi-molten state, thus ensuring high-quality coating formation.

Thermal spraying is the process of heating a material in the form of a powder or wire to a molten or semi-molten state and spraying it at high velocity onto a substrate surface to form a coating. The basic steps include heating the source material to a molten or semi-molten state. The molten particles are accelerated and sprayed onto the substrate surface by means of a high-pressure gas stream or electric arc. The particles cool and solidify on the substrate surface to form a dense coating.

Fig. 2 Thermal Spray Dimensional Repair

The role of the heating furnace in thermal spraying includes:

1. Providing the melting temperature:

Material Heating: The furnace is used to heat the coating material to a molten or semi-molten state, typically in the range of 1000°C to 3000°C. The furnace is also used to heat the coating material to a molten or semi-molten state.

Temperature control: The heating temperature is precisely controlled to ensure that the material achieves the appropriate fluidity and adhesion to form a uniform coating.

2. Promotion of particle acceleration:

Efficient energy transfer: The heating furnace provides high energy so that the material particles in the molten state gain enough kinetic energy to impact the substrate surface at high speed.

Uniform heating: Ensure that the material particles are heated uniformly to avoid coating defects caused by uneven temperatures.

3. Control of coating properties:

Coating structure: The heating furnace controls the microstructure and macro characteristics of the coating by adjusting the temperature and spraying parameters.

Coating properties: optimize the heating process to improve the coating's mechanical properties, corrosion resistance, and thermal stability.

Thermal spraying is divided into arc spraying heating, flame spraying heating, plasma spraying heating, and high-frequency induction spraying according to the heating method used.

1. Arc Spraying (Arc Spraying): The high temperature (about 3000°C) generated by the use of electric arc discharge melts the material, so that the sprayed material (such as zinc, and aluminum), so that it melts and sprayed to the surface of the substrate, forming a dense protective coating. Suitable for metal and alloy materials, characterized by high efficiency and rapid deposition. Widely used in anti-corrosion coatings, conductive coatings, and wear protection coatings.

2. Flame Spraying: The material is heated by a flame generated by the combustion of gaseous fuels (e.g., acetylene, hydrogen) and oxygen. The material is melted by flame heating and sprayed onto the surface of the substrate to form a uniform coating. The flame spraying process is simple and suitable for rapid deposition of coatings over large areas. It is suitable for metal, ceramic, and polymer coatings, and is widely used for surface repair and strengthening of mechanical parts. The equipment is simple, easy to operate, and suitable for various materials.

3. Plasma Spraying (Plasma Spraying): High-temperature plasma (up to 10,000°C) is generated by arc heating, melting the sprayed material. Using plasma high-temperature heating materials (such as alumina, yttrium oxide stabilized zirconia), so that it melts and high-speed spraying to the surface of the substrate, the formation of dense, strong bonding force coating. Suitable for high melting point materials (e.g., ceramics) with high densification and strong coating bonding. They are used for high-temperature protective coatings, wear-resistant coatings, and biomedical coatings.

Fig. 3 Plasma Spraying System

4. High-frequency Induction Heating Spraying: Heating the wire with a high-frequency electromagnetic field to melt and spray onto the surface of the substrate to form a high-quality coating. High-frequency induction heating has the advantages of fast heating and precise control. The fast-heating speed and precise temperature control make it suitable for materials that need to be heated quickly. Used for wire spraying, it is suitable for creating high-strength, wear-resistant coatings.

Conclusion

Heating furnaces are integral to the success of Physical Vapor Deposition (PVD) processes. They provide the essential temperature control needed for evaporation, sputtering, and other material transfer methods, directly impacting the quality of the thin films produced. By maintaining precise temperature conditions, heating furnaces ensure stable evaporation rates, uniform vapor flow, and optimal film properties, such as crystal structure, density, and stress levels. Stanford Advanced Materials (SAM) offers a range of high-quality muffle furnaces designed to meet the rigorous demands of PVD applications, helping to achieve superior coating results across various industries.

References:

[1] R. R. Gilman, Czochralski and Floating Zone Crystal Growth of Modern Materials, Springer, 2012.

[2] G. Müller, "Handbook of Crystal Growth: Bulk Crystal Growth," Elsevier, 2014.

[3] Guo Qin-Min, Qin Zhi-Hui. Development and application of vapor deposition technology in atomic manufacturing. Acta Phys. Sin., 2021, 70(2): 028101. doi: 10.7498/aps.70.20201436

[4] R. F. C. Farrow, "Molecular Beam Epitaxy: Applications to Key Materials," Noyes Publications, 1995.

[5] L. L. Chang and K. Ploog, "Molecular Beam Epitaxy and Heterostructures," Springer, 2013.

[6] Lech Pawlowski, "The Science and Engineering of Thermal Spray Coatings," John Wiley & Sons, 2008.

[7] Robert C. Tucker Jr., "Thermal Spray Technology," ASM Handbook, Volume 5A, ASM International, 2013.

[8] Gerd W. Becker, "Industrial Furnaces: Heat Treatment Equipment," Wiley-VCH, 2014.