Ductility of Common Materials

What Is Ductility

Ductility is a measure of a material's capacity to sustain plastic deformation under tensile stress. Materials with high ductility can be stretched into wires or deformed without breaking. This property is crucial in manufacturing processes where materials are shaped into desired forms.

Importance of Ductility in Engineering

Ductility plays a vital role in engineering and construction. It allows materials to absorb energy during deformation, providing safety and flexibility in structures. Ductile materials can withstand impacts and dynamic loads without catastrophic failure, making them ideal for use in buildings, bridges, and automotive components.

Relation to Malleability

Ductility and malleability are both forms of material plasticity, which refers to a material's ability to undergo permanent deformation without breaking or fracturing. Although these two terms are closely related, they describe different types of deformation behavior in materials.

Ductility

- Definition: Ductility refers to a material’s ability to undergo significant deformation, especially stretching or elongation, before failure or fracture. This is usually demonstrated through processes like drawing (e.g., stretching metal into wire).

- Key Characteristics:

- Materials that are ductile can be pulled or stretched into wires.

- Ductility is often measured by the percent elongation or the reduction in area at the point of fracture in a tensile test.

- Ductile materials can absorb significant strain without failing.

- Examples: Gold, copper, aluminum, and steel (at room temperature).

Malleability

- Definition: Malleability refers to a material’s ability to undergo significant deformation under compression without breaking. It is usually demonstrated through processes like rolling or hammering (e.g., flattening metal into sheets).

- Key Characteristics:

- Malleable materials can be hammered, rolled, or pressed into thin sheets.

- Malleability is generally tested by how much a material can be flattened without cracking.

- Malleability is particularly important in manufacturing processes like forging and extrusion.

- Examples: Gold, lead, and aluminum.

|

Property |

Ductility |

Malleability |

|

Type of Stress |

Tensile (stretching) |

Compressive (flattening) |

|

Key Behavior |

Ability to elongate or stretch |

Ability to deform under compression |

|

Test Example |

Drawing wire, tensile test (elongation) |

Hammering or rolling into thin sheets |

|

Examples |

Gold, copper, aluminum |

Gold, lead, aluminum |

For more information, please check Stanford Advanced Materials (SAM).

Factors Affecting the Ductility of Metals

Several factors influence the ductility of metals, including:

- Temperature: Higher temperatures generally increase ductility.

- Alloying Elements: The addition of certain elements can enhance or reduce ductility.

- Grain Size: Finer grains typically improve ductility.

- Processing Methods: Techniques like annealing can modify ductile properties.

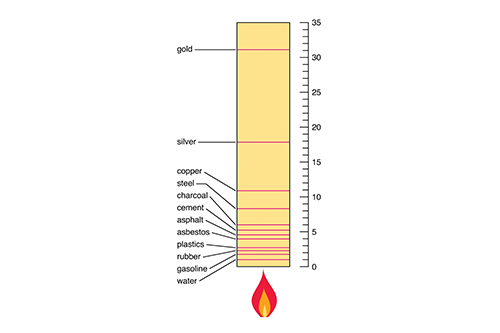

Ductility of Common Materials

Common ductile materials include:

- Metals: Copper, aluminum, and steel are known for their high ductility.

- Alloys: Brass and certain stainless steels exhibit excellent ductile characteristics.

- Polymers: Some polymers can also display ductile behavior under specific conditions.

Here's a Ductility of Common Materials table that outlines the ductility of various materials.

|

Material |

Ductility |

Notes |

|

Gold |

Very High |

Gold is highly ductile, can be drawn into extremely thin wire. |

|

Copper |

High |

Excellent ductility, used for electrical wiring. |

|

Aluminum |

High |

Can be stretched or drawn into thin sheets or wire. |

|

Silver |

High |

Ductile, used in jewelry and electrical applications. |

|

Steel (Low Carbon) |

High |

Very ductile, used in construction, can be stretched or drawn. |

|

Steel (High Carbon) |

Moderate to Low |

Less ductile than low carbon steel, more prone to brittleness. |

|

Moderate to High |

Titanium is moderately ductile but can become brittle at low temperatures. |

|

|

Nickel |

Moderate |

Exhibits moderate ductility, used in alloys and coatings. |

|

Brass |

Moderate |

Brass is moderately ductile, used in plumbing and electrical fittings. |

|

Lead |

High |

Very malleable but also ductile, can be drawn into thin sheets. |

|

Iron (Cast) |

Low |

Brittle and not very ductile, primarily used in casting. |

|

Iron (Wrought) |

High |

More ductile than cast iron, used for structural applications. |

|

Zinc |

High |

Can be easily deformed, commonly used in galvanizing steel. |

|

High |

Platinum is highly ductile and resistant to corrosion. |

|

|

Low |

Extremely strong but very brittle at room temperature. |

|

|

Inconel (Nickel-Chromium Alloy) |

Moderate to High |

Exhibits good ductility at elevated temperatures. |

|

Brass (Copper-Zinc Alloy) |

Moderate |

Good ductility for many industrial applications. |

|

Magnesium |

Moderate |

Magnesium alloys are moderately ductile and lightweight. |

|

Polyethylene (Plastic) |

High |

Flexible and can be stretched significantly before breaking. |

|

Rubber |

Very High |

Extremely ductile, can stretch many times its original length. |

Frequently Asked Questions

What is the difference between ductility and malleability?

Ductility refers to a material's ability to be stretched into a wire, while malleability is the ability to be hammered or rolled into sheets.

Why is ductility important in construction?

Ductility allows materials to deform without breaking, providing flexibility and safety in structures subjected to dynamic forces like earthquakes.

Can polymers be ductile?

Yes, certain polymers exhibit ductile behavior under specific conditions, allowing them to be molded or stretched without breaking.

How does temperature affect the ductility of metals?

Generally, increasing temperature enhances the ductility of metals by allowing atoms to move more freely, facilitating deformation.

What are some applications of ductile wires?

Ductile wires are used in electrical systems, telecommunications, jewelry making, and various industrial applications requiring reliable, flexible strands.