Alumina Bushing Description

Alumina Bushings, made from high-purity aluminum oxide (Al2O3), are renowned for their exceptional properties, making them ideal for various demanding applications. These bushings exhibit excellent thermal stability, withstanding high temperatures without degrading. Their outstanding mechanical strength and hardness ensure durability and resistance to wear, making them suitable for environments with high friction and mechanical stress. Alumina bushings are also chemically inert, resisting corrosion and chemical attacks, which is crucial in harsh chemical environments. Furthermore, their excellent electrical insulation properties make them valuable in electrical and electronic applications. These characteristics—high thermal stability, mechanical strength, chemical resistance, and electrical insulation—make alumina bushings essential components in industries such as aerospace, electronics, chemical processing, and industrial manufacturing.

Alumina Bushing Specification

|

Composition

|

UNIT

|

Al95

|

Al99

|

Al997

|

|

Al2O3 Content

|

%

|

95

|

99

|

99.7

|

|

Color

|

|

White

|

Ivory

|

Ivory

|

|

Tensile Strength

|

Kpsi

|

32

|

38

|

36

|

|

Flexural Strength

|

Kpsi

|

52

|

55

|

54

|

|

Compressive Strength

|

Kpsi

|

300

|

377

|

350

|

|

Density

|

g/cc

|

3.70

|

3.90

|

3.92

|

|

Hardness

|

HV, GPa

|

13.8

|

17.2

|

18

|

|

Thermal Conductivity

|

W/(m K)

|

25

|

30

|

30

|

|

C.O.T.E.

|

In / In°C (x10^-6)

|

7.7

|

7.8

|

7.8

|

|

Working Temperature

|

°C

|

1500

|

1650

|

1750

|

|

Dielectric Constant

|

|

9.5

|

9.7

|

9.8

|

|

Volume Resistivity (25°C)

|

Ohm-cm

|

>10^14

|

>10^14

|

>10^14

|

*This chart just demonstrates the typical properties of common alumina materials we use to produce our alumina parts. Please notice that the property for customized alumina parts could vary due to different process. Stanford Advanced Materials could provide alumina products produced under your specified instruction, or do the best to meet customers’ requirements.

Alumina Bushing Al2O3 Applications

Alumina Bushings, due to their exceptional thermal stability, mechanical strength, chemical resistance, and electrical insulation properties, find extensive applications across various industries. In the electrical and electronics industry, they serve as insulators, connectors, and spacers in high-voltage and electronic components. Aerospace and defense sectors utilize them for thermal insulation and wear-resistant bearings in high-temperature environments. In industrial manufacturing, alumina bushings are used in machinery components and rotating shafts to reduce wear and friction. The chemical processing industry employs them in corrosion-resistant components, seals, and gaskets. The automotive industry uses them in high-performance engine parts and electrical insulation systems. Medical devices benefit from their use in prosthetic components and surgical instruments. In renewable energy, they are utilized in wind turbine components and solar energy systems. These applications highlight the versatility and critical role of alumina bushings in ensuring performance and reliability in demanding conditions.

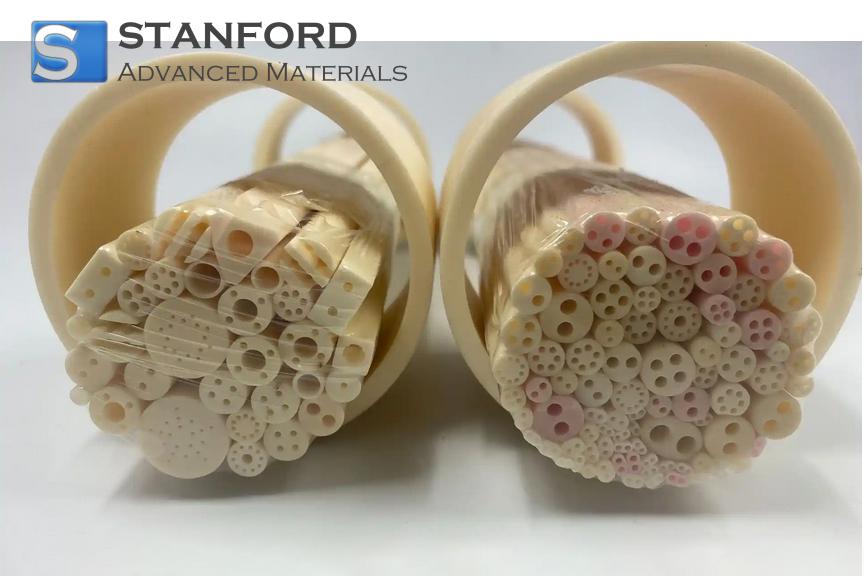

Alumina Bushing Packaging

Our alumina bushing is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

Prototyping service also available for other ceramics material