Calcium Copper Titanate Powder: Properties and Applications

Introduction

Calcium Copper Titanate (CCTO) powder, with the chemical formula CaCu₃Ti₄O₁₂, is a remarkable ceramic material known for its unique electrical properties. This high-dielectric material has attracted significant attention in recent years for its potential in advanced electronics and energy storage applications. With its high dielectric constant, low loss, and ferroelectric characteristics, CCTO powder opens up exciting possibilities in capacitors, sensors, batteries, and more.

Let’s discuss the unique properties and diverse applications of CCTO.

Properties of Calcium Copper Titanate Powder

1. High Dielectric Constant

CCTO powder possesses an exceptionally high dielectric constant, often measured between 10,000 and 100,000 at room temperature, depending on synthesis and processing methods. This enables it to store significant electrical energy, making it ideal for high-capacitance capacitors.

In comparison, traditional dielectric materials like barium titanate typically reach only 3,000 to 5,000, allowing CCTO to enable smaller, more efficient capacitors in high-density energy storage applications.

2. Low Dielectric Loss

CCTO powder has a low dielectric loss factor, typically <0.05 at room temperature for frequencies up to 10 MHz. This low loss is crucial for applications operating at high frequencies, such as telecommunications, where energy dissipation must be minimized.

For instance, CCTO-based capacitors can maintain efficiency in radar systems or high-frequency circuits without excessive heat buildup, ensuring stable performance.

3. Ferroelectric and Piezoelectric Properties

CCTO exhibits ferroelectric properties with polarization values ranging from 0.1 to 0.2 μC/cm² at room temperature. This polarization retention makes it suitable for memory storage applications, where electric fields are used to control data states.

Additionally, CCTO’s piezoelectric coefficient, around 2-5 pC/N, allows it to generate electrical charges in response to mechanical stress, making it effective for applications like vibration sensors and actuators.

4. Multiferroic Behavior

As a multiferroic material, CCTO combines both electric and magnetic ordering at room temperature. The material’s magnetoelectric coupling has been measured up to 0.01 V/cm-Oe, which enables it to manipulate both electric and magnetic states simultaneously.

This feature is valuable in spintronic devices and advanced data storage, where such multifunctionality can improve device efficiency and miniaturization.

5. High-Temperature Stability

CCTO is thermally stable up to 1,000°C, maintaining its dielectric properties without significant degradation. This resilience makes it suitable for high-temperature environments in automotive and aerospace electronics, where standard materials would fail.

In comparison, typical ceramic materials may start to degrade around 600-800°C, giving CCTO a distinct advantage in high-performance, high-stress applications.

Synthesis of Calcium Copper Titanate Powder

Calcium Copper Titanate powder is typically synthesized through various methods, including solid-state reactions, sol-gel processing, and hydrothermal techniques. The solid-state reaction method, which involves mixing calcium carbonate (CaCO₃), copper oxide (CuO), and titanium dioxide (TiO₂) and heating them at high temperatures, is the most widely used approach due to its simplicity and efficiency.

The sol-gel method offers better control over the particle size and shape, which can be beneficial for specific applications that require uniform powder characteristics. The hydrothermal method, meanwhile, can produce high-purity CCTO with excellent crystallinity, which is ideal for electronic and sensor applications. Each synthesis method provides unique advantages, depending on the intended application of the material.

Applications of Calcium Copper Titanate Powder

1. High-Capacitance Electronic Components

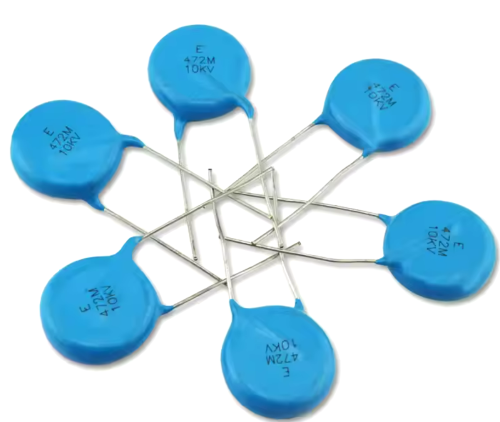

Due to its high dielectric constant, CCTO powder is an excellent material for producing high-capacitance capacitors. These capacitors are essential for energy storage in various electronic devices, particularly those requiring high energy density, such as smartphones, laptops, and electric vehicles.

The high capacitance of CCTO-based capacitors allows for more efficient storage and delivery of electrical energy, which is crucial in power management and stability for modern electronic systems.

2. Vibration Damping and Acoustic Sensors

CCTO powder can be used in vibration damping devices due to its piezoelectric properties. In high-frequency electronic equipment, CCTO’s ability to dampen vibrations helps improve performance and stability by minimizing noise and interference. This feature is especially useful in automotive and industrial machinery, where vibration control is critical.

The piezoelectric characteristics of CCTO also enable its application in acoustic sensors, where it can convert sound or pressure waves into electrical signals. These sensors are used in a range of industries, from automotive to medical devices, where they detect sound, pressure changes, or structural vibrations.

3. Next-Generation Batteries

With its unique electrochemical properties, CCTO powder is being explored for use in next-generation battery technologies. CCTO’s high energy density and cycling stability make it suitable for enhancing the capacity and lifespan of rechargeable batteries. These attributes are particularly valuable in applications like electric vehicles and portable electronics, where battery performance and longevity are critical.

Researchers are investigating CCTO’s potential to improve lithium-ion batteries and other emerging battery technologies, such as solid-state batteries. The stability of CCTO in high-temperature environments further supports its use in batteries that must operate reliably over extended periods and in demanding conditions.

4. Solar Energy Cells

In the field of solar energy, CCTO powder has the potential to increase the efficiency and stability of solar cells. By improving the energy conversion efficiency, CCTO-based materials can enhance the performance of photovoltaic cells, promoting the adoption of renewable energy sources. CCTO’s high dielectric constant and low loss factor allow for better energy capture and conversion in solar panels, making it a promising material for sustainable energy solutions.

5. Aerospace Capacitors

Thanks to its high-temperature stability and mechanical durability, CCTO powder is also valuable in aerospace applications. Capacitors made from CCTO are capable of withstanding the harsh conditions encountered in aerospace environments, where components are subjected to extreme temperatures, vibrations, and radiation. These capacitors help improve the reliability and longevity of electronic systems in aircraft and spacecraft, where component failure can have serious consequences.

Conclusion

Calcium Copper Titanate powder stands out for exceptional dielectric properties and advanced applications. From high-capacitance capacitors to piezoelectric sensors, next-generation batteries, and solar cells, CCTO powder plays a pivotal role in energy storage, signal conversion, and environmental sustainability. Its multiferroic properties and high-temperature stability also open up possibilities for use in aerospace and other demanding industries.

Stanford Advanced Materials (SAM) offers high-quality Calcium Copper Titanate Powder at the most competitive prices. With years of expertise in supplying premium ceramic dielectric materials, SAM ensures reliable, top-grade products for various applications. Send us an inquiry if you are interested.