Influence of Nanomaterial in Soft Soil Stablization: Nanosilica & Nanoclay

Abstract

Engineers and designers frequently utilize the procedure to improve soil by adding various stabilizers, which are typically used to improve the quality of soil. Modern methods such as adding nanoparticles to weak natural soil to fill in gaps at the nanoscale or between 1nm and 100 nm, and to enhance all geotechnical qualities are known as nanotechnology. In this investigation, laboratory tests were done to assess how well soft soil stabilized by Nano-soil particles—nanoclay & nanosilica—performed on the geotechnical parameters. The major goal of this study is to investigate how modest concentrations of nanosilica and nanoclay (0.05%, 0.15%, 0.25%, and 0.35%) can improve the physical qualities of soil. The stabilization of soil using nanomaterials has demonstrated good results, increased all geotechnical parameters including index and engineering properties, and improved soil strength and effectiveness shear strength of stabilized soft soil. It also provided the soil with the ideal dose of the nanoclay effect. Dry densities of 1.81kN/m2 were attained at 1% nanosilica and 0.15% nanoclay. After 28 days of curing, the unconfined compression strength characteristics increased from 0.201 MPa to 0.821 MPa at 1% nanosilica and 0.15% nanoclay, as the porous space filled with nano-particles and the soil's compressive strength improved. Stabilization is beneficial for all embankments related to slope stability, transportation, geotechnical, and civil stability.

Keywords

Nanosilica, Nanoclay, Unconfined Compressive Strength, Standard Proctor Test

1. Introduction

The rarely can naturally clayey soils satisfy the foundational bearing capacity specifications of contemporary geotechnical engineering projects. Because of their high compressibility, high swell and shrink potential, poor permeability, low shear strength, and low permeability, soft soils are regarded as problematic soils. According to [2], soft soil is said to have unpredictable behavior and undesired engineering qualities. The process of adding materials to the soil or changing its natural features in order to improve its engineering qualities—such as strength, durability, and resistance to deformation is known as soil stabilization. Three general categories can be used to categorize soil stabilization techniques: mechanical, chemical, and physical techniques. In general, foundation soils can have their strength and deformation qualities altered or improved by adding a range of reinforcement or treatment materials [7], [13], [12], [19] & [20]. These compounds fall into three categories: composite curing agents, ionic soil stabilizing substances, and inorganic binders. For chemical soil modification, inorganic binders (such as cement, lime, fly ash, and their mixes) are commonly utilized among other stabilized materials [3]. According to [18], with lower initial mean effective stresses or higher cement content, cemented soils show more brittle stress-strain behavior and a considerable rise in elastic modulus and peak strength. According to [12], adding polypropylene fibers to cemented soil raises the fiber content, which in turn raises the principal stress ratio at failure as well as the peak and residual shear strengths. In a series of experiments, [15] added nano-silica to clayey soils and discovered that this resulted in a decrease in the clay's swelling index. Researchers interested in engineering applications, particularly in civil engineering, are becoming more and more interested in nanomaterials and nanoparticles these days. Nanomaterials are a class of ultra-fine materials that have particle sizes ranging from 1 to 100 nm with a huge specific surface area. Due to a growth in the surface area overall and their ability to function as effective catalysts, nanoparticles become more reactive than their initial size and can develop materials with new uses. Rather, the huge surface area of a nanoparticle will enhance the amount of contact between the intermixed components, like in nano-composites, increasing the strength of the materials. As a result, it becomes more reactive and might be useful for enhancing the characteristics of soil for a range of uses. A particular kind of nanoparticle known as nanosilica is made up of minuscule silicon dioxide particles. Nanosilica can have a number of benefits when applied to clay soil, some of which can enhance soil quality. When clay is stabilized using additives such as fly ash, cement, silica fume, and lime, the particles are micro-sized and have little effect on the properties of the pores, including compaction, shear strength, specific gravity, plasticity index, and permeability [4] [16]. These additions alone do not sufficiently increase soil performance; the gaps are only partially filled. In order to fill in soil pores at the nano-scale and make the soil more compacted, nanotechnology is employed [17] [9] [1]. This has a greater overall impact on the soil's permeability, specific gravity, compaction, shear strength, and plasticity index. The size effect, quantum effect, surface effect, and interface effect are the four main structural properties of nanomaterials [6].nanomaterials offer numerous benefits in terms of science, the environment, the economy, and better product quality. Of all the nanomaterials, nanoclay demonstrated superior performance in terms of the soil index and engineering features. It has been demonstrated that adding extremely small amounts of nanoclay to soil improved the liquid limit and had an impact on the plasticity index [21]. Since nanoparticles are widely used, their cost has dropped significantly, opening the door for their widespread use in the geotechnical engineering industry.

The purpose of this study is to look into how nanoparticles affect clay soil. The research has been conducted on clay soil supplemented with nanosilica and nanoclay. To determine the ideal proportion, nanosilica was first added to the mother clay sample in increments of 0.7%, 1%, 1.2%, and 1.5%. The samples were then combined with 0.05%, 0.15%, 0.25%, and 0.35% nanoclay. A comparison was made between the characteristics of a native clayey soil sample and a chemically stabilized clayey soil sample. This work examines an experimental investigation into the efficacy of employing nanomaterials (nanoclay and nanosilica) to enhance the strength qualities and atterberg limit parameters. The outcomes of the experiment demonstrated that adding a little quantity of nanosoil significantly enhanced the soft soil's geotechnical characteristics.

2. Materials and Methods

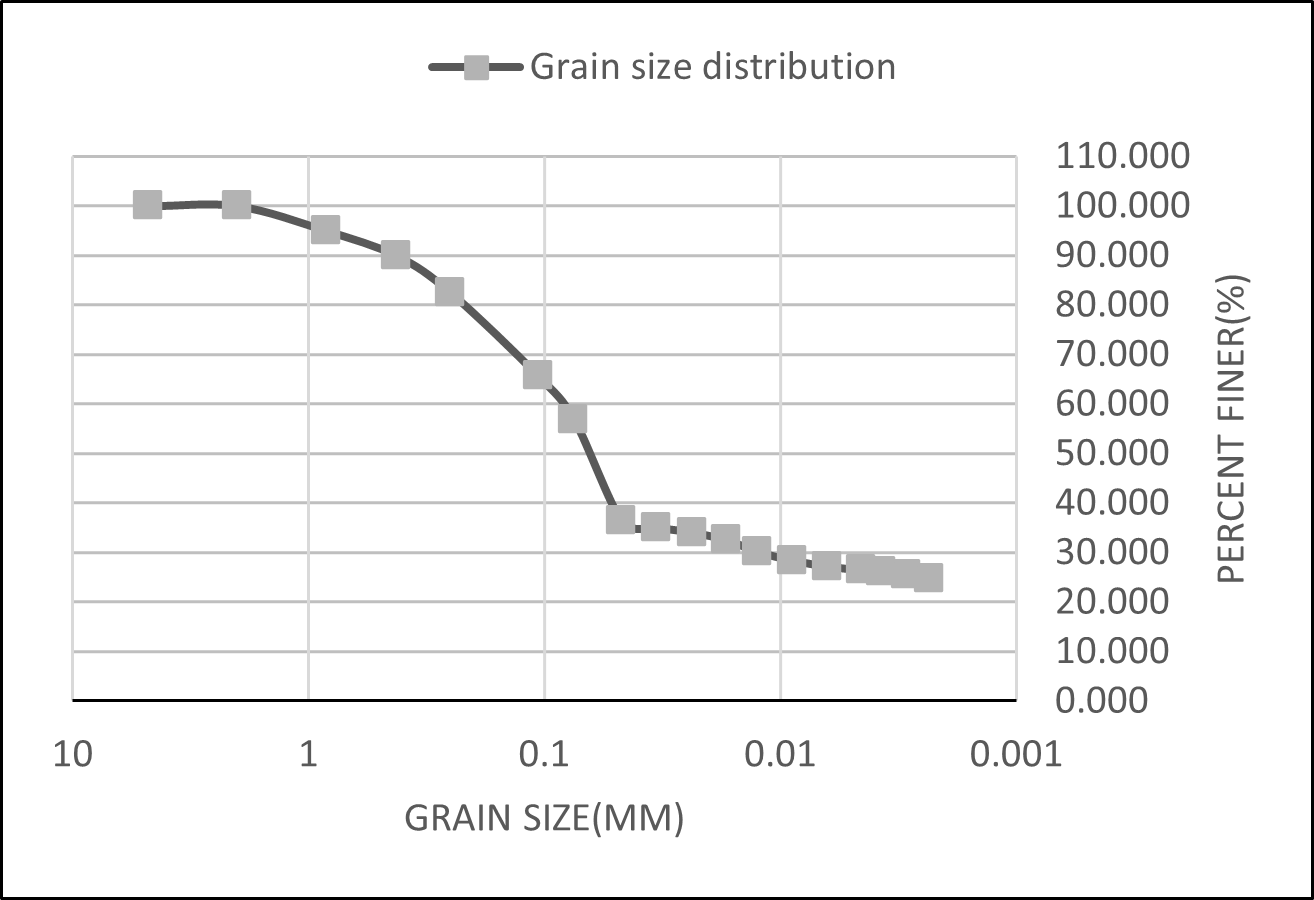

A sample of native soil was taken from Beel Dakatia. It is situated inside the administrative boundaries of Khulna district's dumuria and phultala sub-district, of which 50% area is regularly beneath 0.5 m to 2 m water. It is located between longitudes 89'20'e and 89'35'e and latitudes 22'45'n and 23'00'. The soil that was gathered was lumpy. They were untreated and collected over 25 kg in an unused bag. The soils were then let to dry naturally. To begin with, the earth was damp. The dried dirt lumps were crushed manually after the air drying process was completed. After that, the powdered soils were sieved in accordance to astm c136. The grain size distribution is shown in fig. 1. For experiments it was insufficient so the air-dried soils were oven dried in a 105°c oven for 24 hours. The additive for this study was nanosilica and nanoclay. Nanoclay and nanosilica were added with soil in different percentages for preparing sample. 600 g of nanoclay was collected from kolkata, india. 1kg of nanosilica was collected from khulna scientific store, khulna. The needed amount for testing was oven dried for 24 hours at the soil's temperature. Two types of specimen were prepared for the test. Firstly 0.7%, 1%, 1.2% and 1.5% of nanosilica was mixed with mother soil to investigate the optimum amount of nanosilica. Then, 0.05%, 0.15%, 0.25% and 0.35% of nanoclay was added with soil along with the optimum content of nanosilica to make the specimen for test. Four specimen were prepared on nanosilica and nanoclay for every test. Chemical composition of the used nano silica is shown in Table 1.

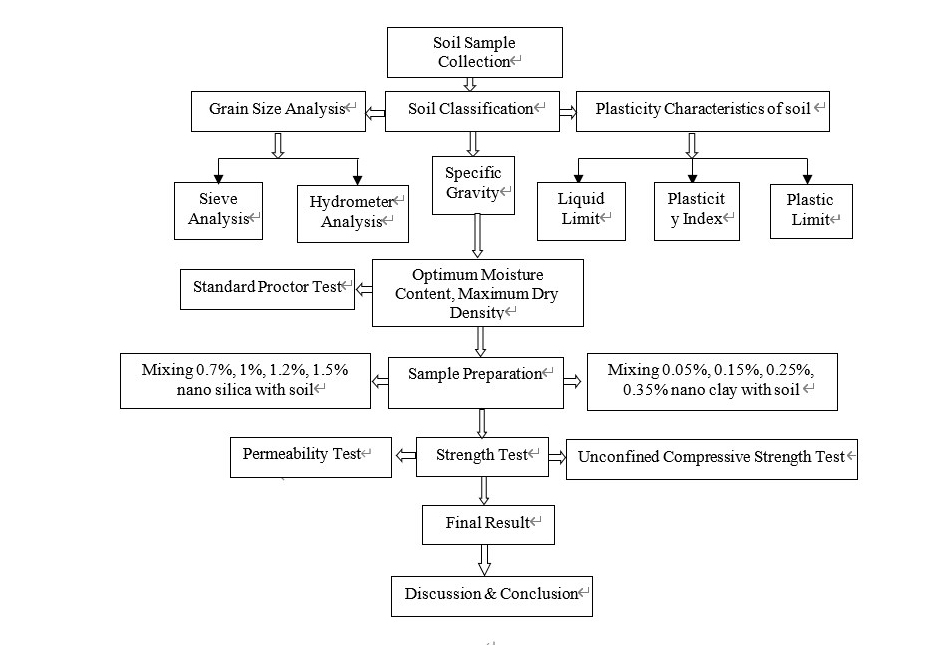

In this research, the mother clayey soil sample was collected from respective area and samples for the tests were prepared in the laboratory. All the tests were performed in the laboratory. The flow diagram of the methodology of this research is given below:

Table1: The chemical composition of the nanosilica that was used

Ingredients | Constituent percentage |

Silicon dioxide(sio2) | 91.5% |

Magnesium oxide (mgo) | 0.085% |

Calcium oxide(cao) | 0.065% |

Sulfur trioxide(so3) | 0.26% |

Aluminum oxide (al2o3) | 0.085 % |

Sodium oxide (na2o) | 0.97% |

Potassium oxide (k2o) | 0.013% |

Titanium dioxide(tio2) | 0.04% |

Ferric oxide (fe2o3) | 0.021% |

Calcium oxide (cao) | 0.4% |

Manganese dioxide (mno) | 0.003% |

Fig. 1: Grain size distribution of the test soil.

3. Results and discussion

3.1 Effect of Nano-silica on soft soil stabilization

3.1.1 Effect of nano-silica on Atterberg limits of soil

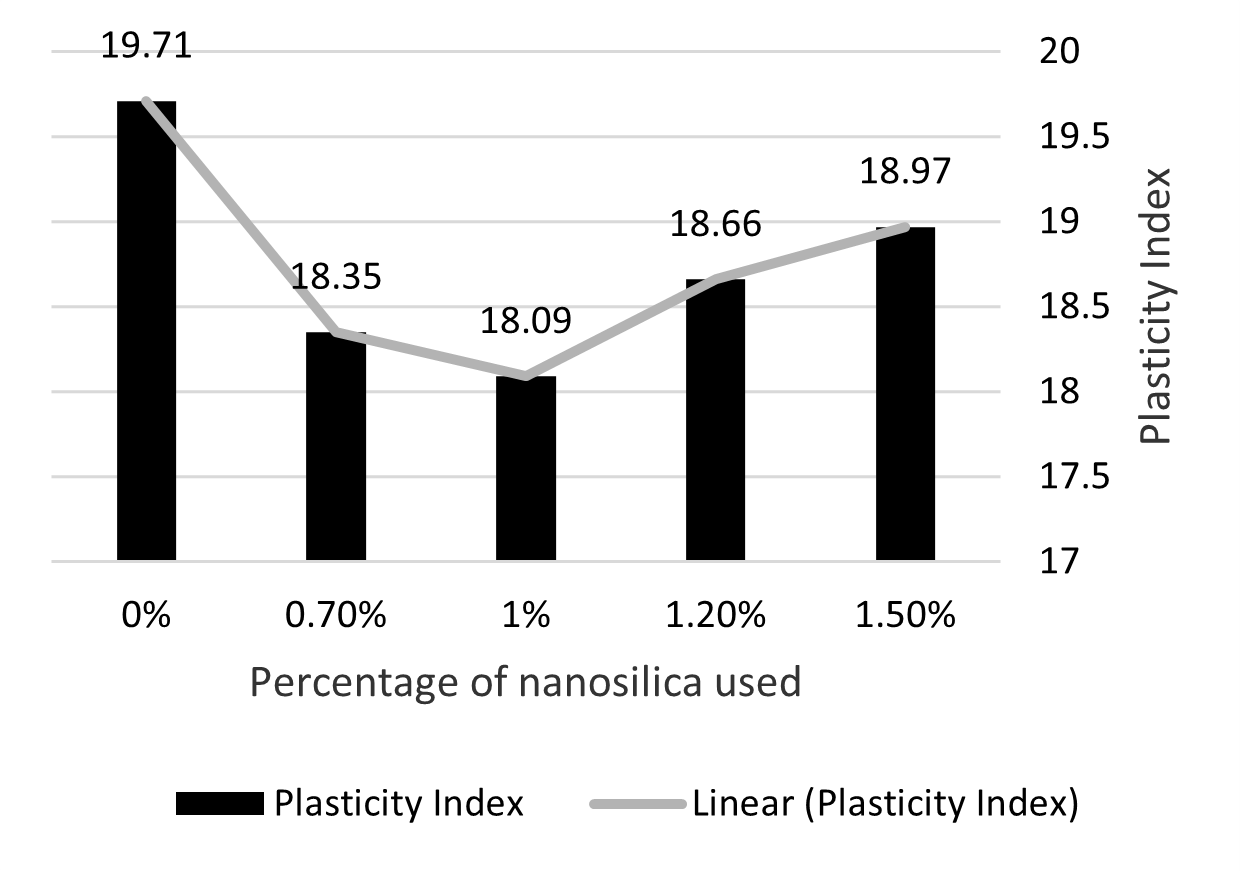

Figure 2 shows the link to the stabilized soil's liquid limit and nano-silica content. In comparison to the mother sample, the stabilized clayey sample has a lower liquid limit value in our test. The liquid limit rises as the proportion of nano-silica increases.. The liquid limit for collected clayey sample was 43.25. The value of liquid limit for stabilized clay with 0.7% nanosilica was 44.33. The liquid limit value 44.64 at 1% nanosilica used to stabilize the soil. In 1.2% of nanosilica used when the liquid limit was 45.43. The liquid limit is maximum for the stabilized sample with 1.5% nanosilica. The maximum value of liquid limit is 45.86. For plastic limit test, plastic limit increased for stabilized soil as nano-silica percentage increased. For mother soil sample, the plastic limit was 23.54. While adding 0.7% nanosilica, the plastic limit increased and the value was 25.98. The plastic limit increased as the percent of nanosilica increased. The plasticity index varies in the test while adding different content in different percentages. The plasticity index was 19.71 for mother sample. The plasticity index lowest for 1% nanosilica stabilized soil with a value of 18.09 for optimum amount. So the 1% of nanosilica shows the best result. The variation of plasticity index is shown in fig. 2. According to (foad changizi, 2017), the result was similar with the experiment. When determining how much a soil is expected to settle or consolidate under load, the atterberg limits can be used as a reference in the field. If the field moisture is near the liquid limit, a lot of settling is expected. The opposite is true if the field moisture is close to or below the plastic limit. In our experiment, the plasticity index decreases then rises, the liquid limit rises, and the plastic limit rises.. That example, when 1% nanosilica is used to stabilize the soil, the pace of settlement is reduced. So as a chemical additive, 1% of nanosilica is an optimum stabilizer that enhances the properties of clayey soil samples.

3.1.2 Effect of nano-silica on compaction characteristics of soil

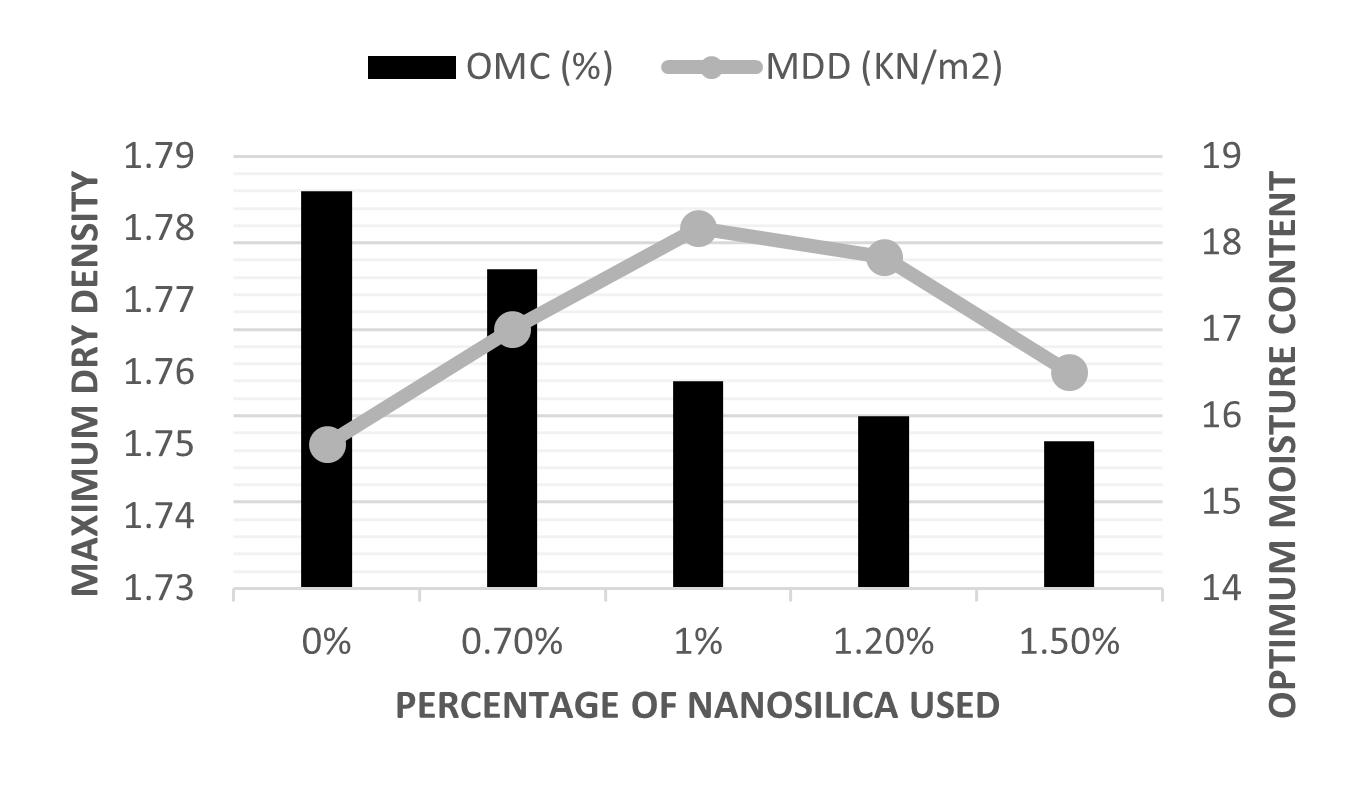

The standard proctor test was conducted. In the test, the optimum moisture content decreased and maximum dry density increased for the stabilized soil. The optimum moisture content was 18.6% for mother clay soil. Afterwards the optimum moisture content decreased as nano-silica percentage increased with lowest at 1.5% nanosilica reaching 15.7 %. The maximum dry density was 1.75 KN/m2, 1.766 KN/m2, 1.78 KN/m2, 1.77 KN/m2, and 1.76 KN/m2 for clay soil, 0.7% nanosilica, 1% nanosilica, 1.2% nanosilica and 1.5% nanosilica stabilized soil respectively. This results are similar with [5] [1].

Fig. 2: Plasticity Index (Untreated Soil + Nano-silica)

Fig. 3: Compaction characteristics of nanosilica mixed soil sample

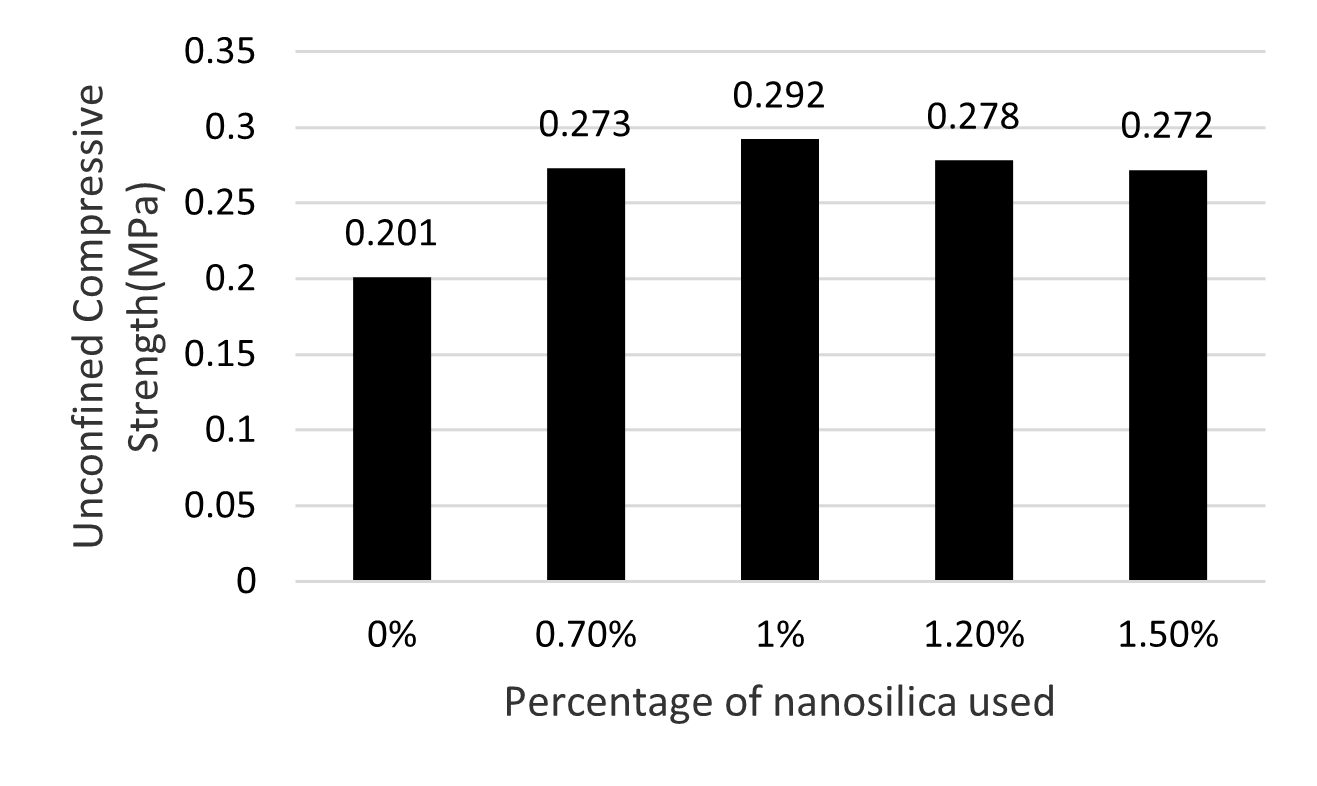

3.1.3 Effect of nano-silica on Unconfined Compressive Strength Test

The Unconfined Compression Test (UCT) was used for determining the mechanical characteristics of the soil sample. It determines the undrained strength and stress-strain properties of soil. Here the nanosilica 1day strength relationship is shown in figure 4. Among all the percentages 0.7, 1, 1.2, 1.5% of the dry weight of soil, at the percentage 1 of Nanosilica lowest plasticity index (from 21% to 19.5%), and significant maximum dry density (from 1.75 to 1.78 KN/m2). Among all percentages, 1% nano-silica showed best results with UCT value reaching the highest at 1%. So that is why 1% nanosilica was chosen as the optimum dosage for the soil.

Fig. 4: UCT test of nanosilica mixed soil sample

3.2 Effect of Nanoclay on clay soil+ 1% nano-silica

3.2.1 Effect of nano-clay on Atterberg limits of soil + 1% nanosilica

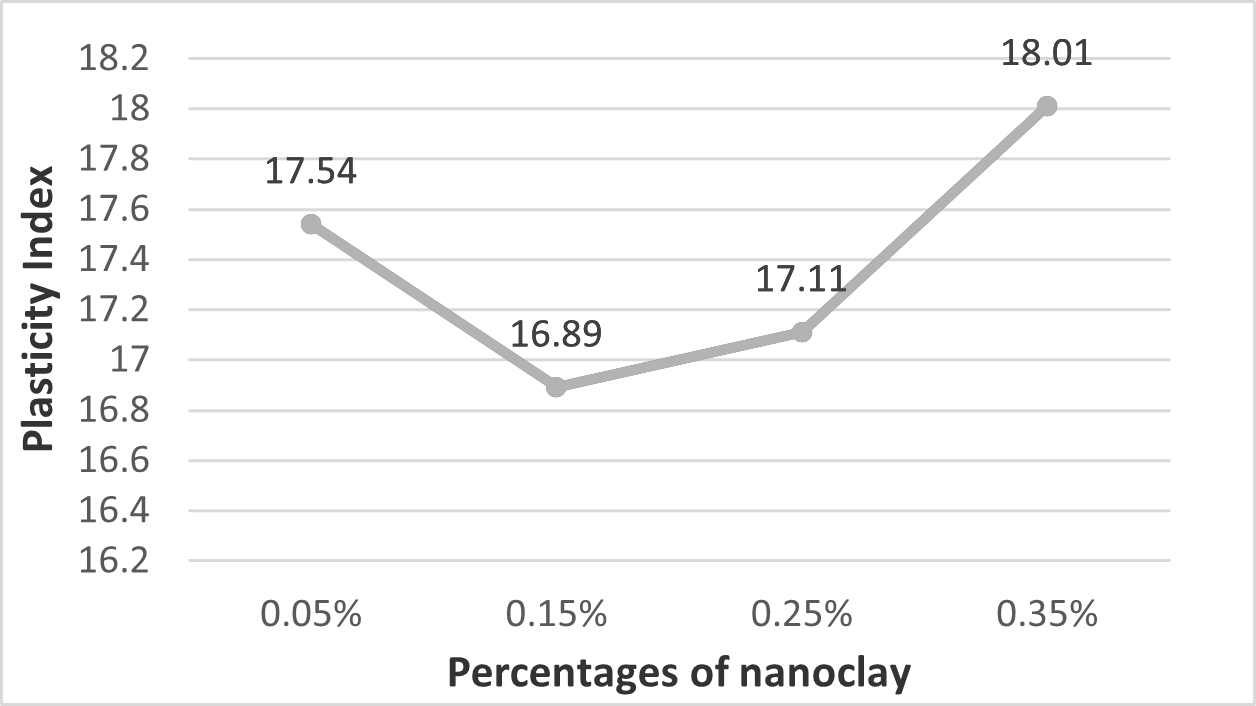

In our test, Liquid limit has less value in stabilized clayey sample than the mother sample. The liquid limit increased with increasing percentages of nanosilica & nanoclay. The liquid limit for collected clayey sample was 43.25. The value of liquid limit for stabilized clay with 1% nanosilica +0.05% nanoclay was 41.57. The liquid limit value was 41.89 at 1% nanosilica+0.15% nanoclay used to stabilize the soil. In 1% of nanosilica + 0.25% nanoclay used when the liquid limit was 45.43. The liquid limit is maximum for the stabilized sample with 1% nanosilica + 0.35% nanoclay. The minimum value of liquid limit is 45.86. In our test, plastic limit increases for stabilized soil. For mother soil sample, the plastic limit was 23.54. While adding 1% nanosilica + 0.05%, the plastic limit increased and the value was 24.25. The plastic limit increased as the percent of nanoclay increased. The plasticity index varies in the test while adding different content in different percentages. The results are in accordance to previous studies using nanoclay [21].The Plasticity index was 19.71 for mother sample. The plasticity index lowest for 1% nanosilica + 0.15% nanoclay stabilized soil with a value of 16.89 for optimum amount [8]. So the 0.15% of nanoclay shows the best result. The variation of plasticity index is shown in Figure 5

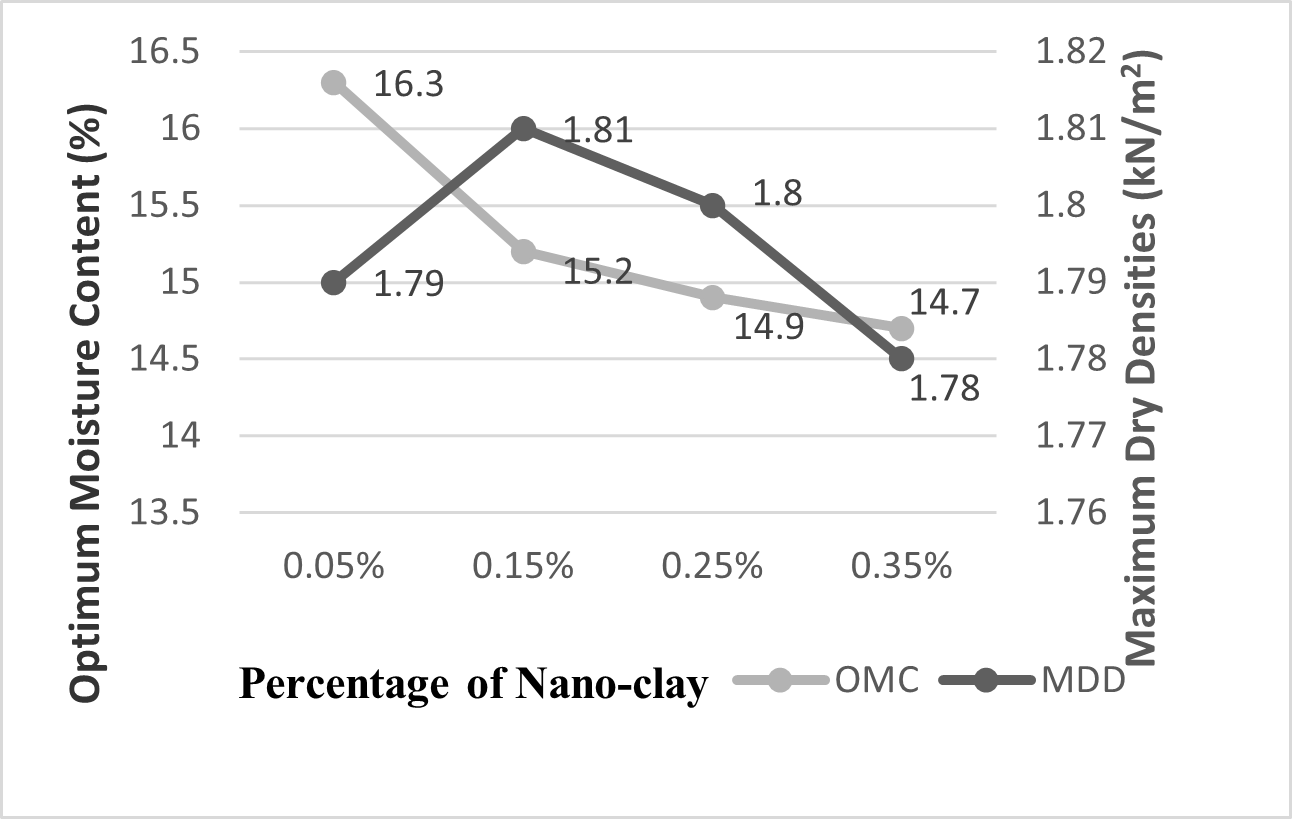

3.2.2 Effect of nano-clay on compaction characteristics of soil + 1% nanosilica

The maximum dry density decreases as the optimal moisture level rises in the test. For mother sample, stabilized clay with 1% nanosilica+ 0.05% nanoclay, 1% nanosilica+ 0.15% nanoclay, 1% nanosilica+ 0.25% nanoclay, and 1% nanosilica+ 0.35% nanoclay the optimum moisture level was 16.3 percent, 15.2 percent, 14.9 percent, and 14.7 percent, respectively. Figure 6 shows the compaction characteristics.We can verify with the results of [11].

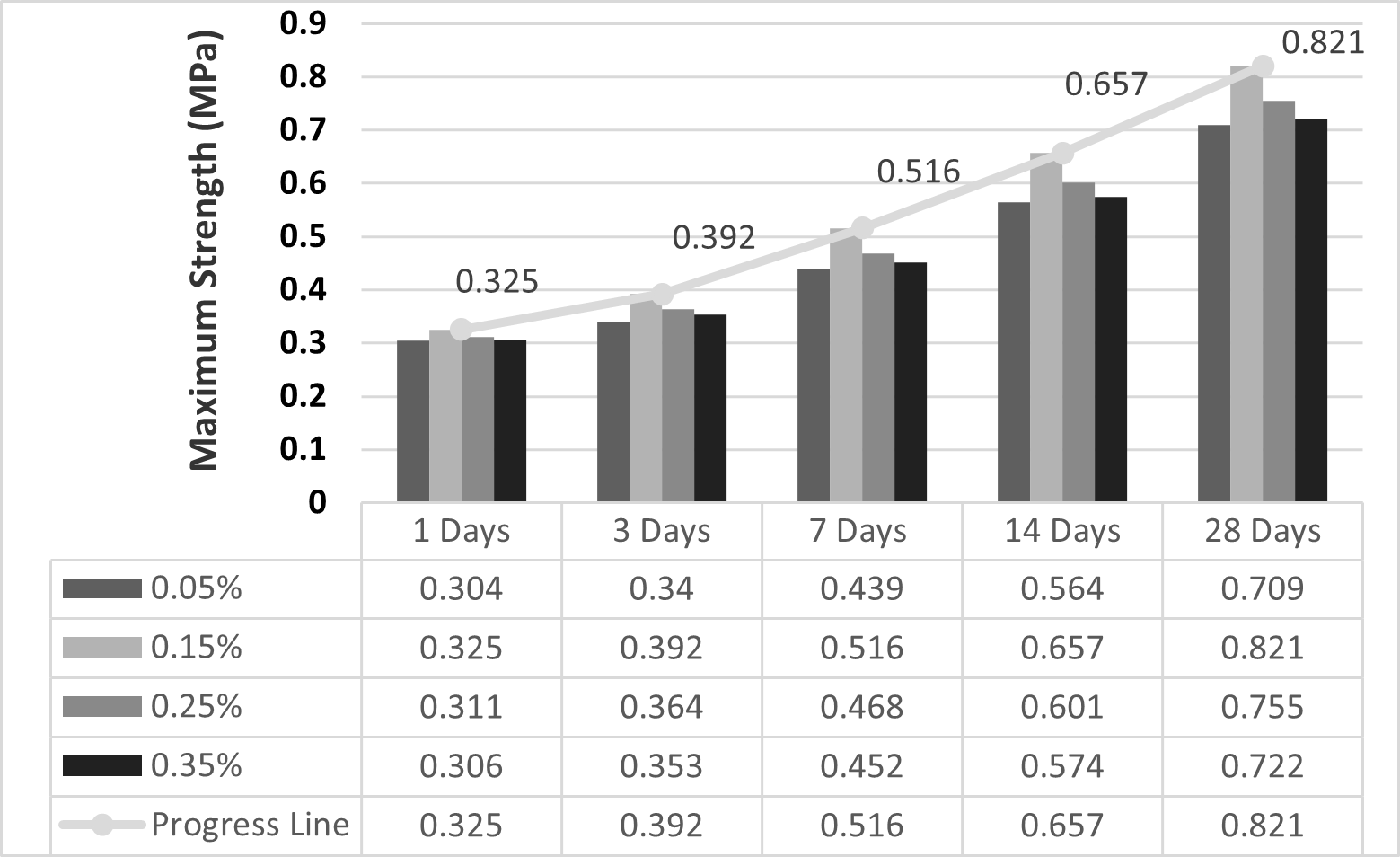

3.2.3 Effect of nano-clay on Unconfined Compressive Strength Test of soil+ 1% nanosilica

To find an ideal combination of nanosilica and nanoclay, the optimum percentage of nanosilica was mixed with different percentage of nanoclay to find an ideal combination of nanosilica and nanoclay, the optimum percentage of nanosilica was mixed with different percentage of nanoclay. UCT test was conducted on 1, 3, 7, 14 and 28 days. At the 14-day test, there was a considerable improvement. This is due to the pozzolanic reaction. After finding optimum nanosilica, nanoclay was added with optimum nanosilica mixed clay soil at different percentage (0.7%, 1%, 1.2%, and 1.5 %) and the maximum strength was found at 0.15% nanoclay and the strength improvement was 67%.We can verify with the results of [11] which are much similar with that. As a result, we discovered the appropriate amount of nano-silica & nano-clay for clay soil stabilization. Results are shown in figure 7.

Fig. 5: Plasticity Index (Clay Soil+ 1% Nanosilica + Nano clay)

Fig. 6 : Compaction characteristics of nanoclay mixed soil sample

After 24 hours the highest strength improvement was found 62 percent at (Nanosilica 1% + Nanoclay 0.15%) combination. Among all the percentages of the dry weight of soil, the percentage 0.15 of Nanoclay treated maximum specific gravity, reduced plasticity index and significant maximum dry density. So 0.15% nanoclay was optimum.

3.3 Effect of 1% nanosilica +0.15% nano-clay on Permeability Test of soft soil

The soft clay soil has been combined with the ideal moisture content, maximum dry density, and optimal doses of nanosilica and nanoclay to prepare the samples for permeability characteristics. The samples were preserved in their final packaging to prevent the evaporation of water. The generated samples met the permeability properties as specified by astm d 2434 and evaluated in accordance with the guidelines. Specifically, the soft-clay soil was combined with the ideal moisture content, maximum dry density, and doses of nanosilica and nanoclay. The findings of the permeability parameters of soil mixed with nanosilica and nanoclay are shown in table 2. This test revealed that the permeability parameters were entirely different from those previously investigated [14]. The addition of the ideal dosage of nanoclay caused the vacuum spaces to fill with nanomaterials at the nano level, acting as completely impenetrable soil.

Table 2: Permeability Characteristics

Soil Type | Untreated soil | Soil+ 1% NS+0.15% NC |

Coefficient of Permeability (cm/s) | 4.6*10-4 | 7.61*10-7 |

Fig. 7:Strength ImprovementVariationforDifferentTestDays (Clay Soil+ 1% Nanosilica + Nanoclay)

4. Conclusions

The following conclusions were drawn from the experimental study on enhanced soft-clay using nanosilica & nanoclay, index, and engineering features of soft-clay:

- Low Compressible Clay (CL) soil is determined by Atterberg's limits. The OMC and MDD of the soil are 18.18% and 1.62 g/cc, respectively.

- The UCS of clay soil was determined to be 0.201 Mpa, and the coefficient of permeability is around 4.6 * 10-4 cm/s. The final consolidation settlement is approximately 4.4 mm, and the consolidation coefficient was found to be 0.043 cm2 /min. So, it is evident that high compressible clay makes up the soil.

- The ideal moisture content, maximum dry density, and percentages of Nanosilica, such as 0.7, 1, 1.2, and 1.5% of the dry weight of soil, have been combined with the soft-clay soil.

- At 1% of nanosilica in the soil, the maximum dry densities raised the maximum 1.78 kN/m2 and affected the distribution of grain sizes.

- Of all the percentages, the strength of 1% nanosilica yields the best results.

- The percentage 1 of Nanosilica treated soil had the lowest plasticity index (from 21% to 19.5%) and the significant maximum dry density (from 1.75 to 1.78 kN/m2) among all the percentages—0.7, 1, 1.2, and 1.5% of the dry weight of soil. To determine the ideal amount of nanosilica to add to the soil, each adjustment is made at a percentage of 1%.

- The inclusion of Nanoclay affected the grain size distribution and altered the liquid and plastic limitations. Maximum reduction in the plasticity index occurred at 0.15% of the soil-mixed Nanoclay.

- The maximum dry densities affected the distribution of grain sizes and raised the maximum 1.81kN/m2 at 0.15% Nanoclay percentage in the soil.

- The highest specific gravity, lowest plasticity index, and significant maximum dry density were observed at the percentage 0.15 of Nanoclay treated soil among all the percentages of the dry weight of soil.To determine the ideal amount of Nanoclay to add to the soil, each adjustment is made at a percentage of 0.15%.

- The soil acted as completely impermeable, the total pores filled with nanomaterials, and the ideal dosage of Nanoclay all had zero permeability properties.

References

[1] A. Mohamadzadeh Sani, M. A. (2010). Effect of Nanoclay additive on the geotechnical properties of silty sands. Proc. of 4th International Conference on Geotechnical Engineering and Soil Mechanics, Tehran, 2–3 November 2010.

[2] A.M., A. W.-A. (2005). Implementation of the electrokinetic process as an effective method for soil improvement. International conference on Problematic soils GEOPROB 2005, Famagusta, N. Cyprus, 885-894.

[3] Cai, Y., & Shi, B. (2006). Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 2006, 230–240.

[4] Feynman, R. (1960). there is plenty of room at the bottom. Eng. Sci. (California Institute of Technology), 22–36.

[5] Foad Changizi, A. H. (2017). Improving the geotechnical properties of soft clay with nano-silica particles. Proceedings of the Institution of Civil Engineers.

[6] Gao, L., & Ren, Z. (2015). Experimental study of nanometer magnesium oxide-modified clay. Soil Mech. Found. Eng. 2015, 218-224.

[7] Hejazi, S., Sheikhzadeh, M., Abtahi, S., & Zadhoush. (2013-14). Shear modeling of fiber reinforced soil composite on the base of fiber pull-out test. Fiber Polym. 2013, 14, 277-284.

[8] Jamal M. A. Alsharef, 1. M. (2016). Potential of Using Nanocarbons to Stabilize Weak Soils.

[9] Jha, K. (2012). An energy based nano mechanical properties evaluation method for cementitious materials. Florida International University, Miami, FL, USA, 2012.

[10] M, H. A. (2013). Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotextiles and Geomembranes, 1-9.

[11] Meeravali Karumanchi, G. A. (2020). Improvement of consistency limits, specific gravities, and permeability characteristics of soft soil with nanomaterial: Nanoclay. www.elsevier.com.

[12] Mirzababaei, M., Miraftab, M., Mohamed, M., & Mcmahon. (2013). Impact of carpet waste fibre addition on swelling properties of compacted clays. Geotech. Geol. Eng. 2013, 173–182.

[13] Mirzababaei, M., Yasrobi, S., & Al-Rawas. (2009). Effect of polymers on swelling potential of expansive soils. Proc. Inst. Civil Eng. Ground Improv. 2009, 111-119.

[14] Norazlan Khalid, M. F. (2015). Influence of nano-soil particles in soft soil stabilization.

[15] QP, P. H. (2014). Effect of silica nanoparticles on clay swelling and aqueous stability of nanoparticle dispersions. Journal of Nanoparticle Research, 2137.

[16] R. Booker, E. B. (2005). Nanotechnology for Dummies. Wiley Publishing, 2005, 384.

[17] R. Zhu, S. L. (2010). A high-resolution TEM investigation of nanoparticles in soils. Environ. Soil Sci. Interfaces Earth Critical Zone, 282-284.

[18] Schnaid F, P. P. (2001). Characterization of cemented sand in triaxial compression. Journal of Geotechnical and Geoenvironmental Engineering , 857-868.

[19] Soltani, A., Deng, A., Taheri, A., & Mirzababaei. (2017). A sulphonated oil for stabilisation of expansive soils. Int. J. Pavement Eng. 2017, 1285–1298.

[20] Soltani, A., Deng, A., Taheri, A., & Sridharan. (2019). Swell–shrink–consolidation behavior of rubber-reinforced expansive soils. Geotech. Test. J. 2019, 761–788.

[21] Z.H. Majeed, M. T. (2012). Effect of nanomaterial treatment on geotechnical properties of a Penang soft soil. Asian Sci. Res. 2 (11) (2012), 587-592.

This is a submission for SAM's 2024 Scholarship, submitted by Tausif Islam Chowdhury.

*Corresponding Author

Tausif Islam Chowdhury* 1, Jhumana Akter 2, Musharrof Hossain Sunny3 & Fahim Shahariar Aditto4

1 Graduate Student, Department of Building Engineering and Construction Management, Khulna University of Engineering & Technology, Bangladesh

2 Assistant Professor, Department of Building Engineering and Construction Management, Khulna University of Engineering & Technology, Bangladesh

3 Graduate Student, Department of Building Engineering and Construction Management, Khulna University of Engineering & Technology, Bangladesh

4 Graduate Student, Department of Building Engineering and Construction Management, Khulna University of Engineering & Technology, Bangladesh