- Products

- Categories

- Blog

- Podcast

- Application

- Document

SN4321 Babbitt Alloy Ingot

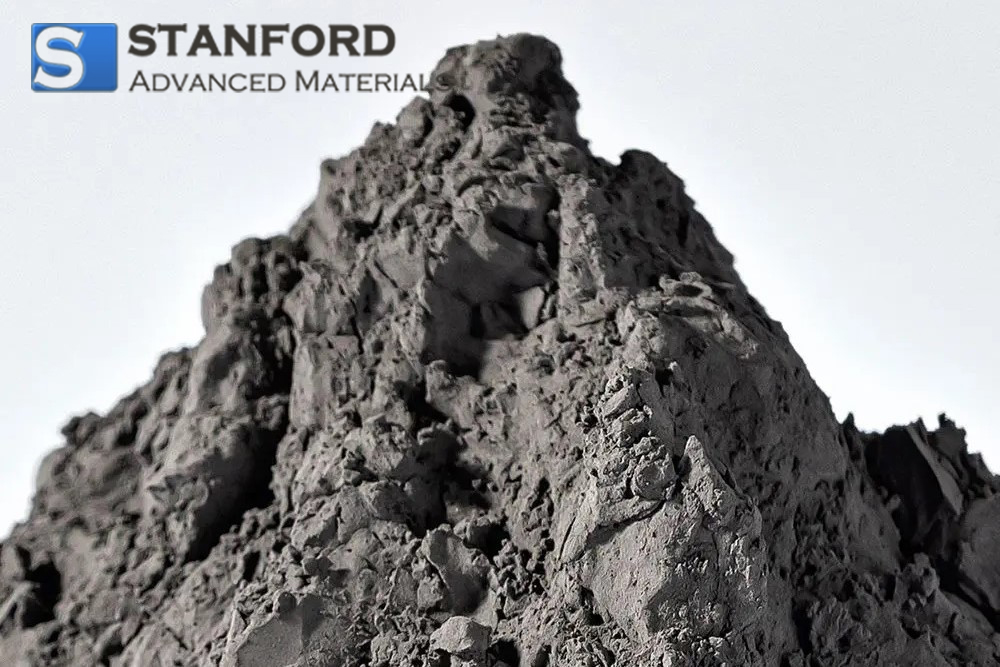

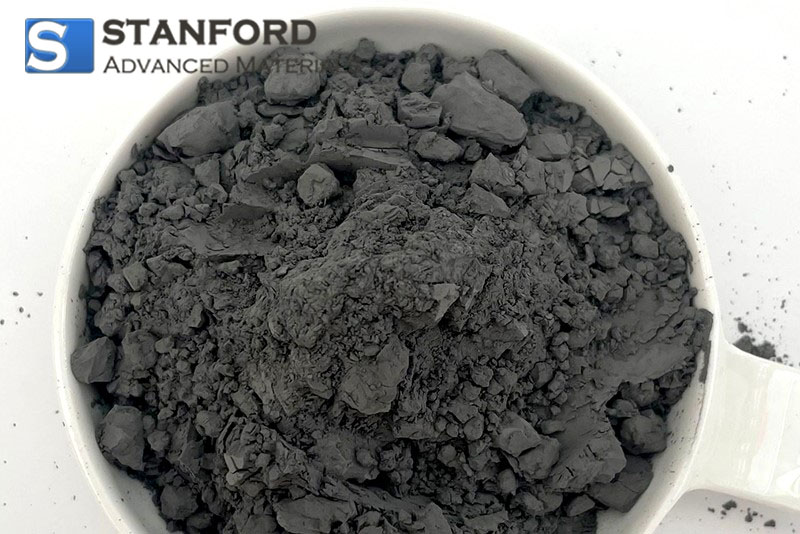

| Catalog No. | SN4321 |

| Compositions | Sn, Sb, Cu |

| Color | Gray |

| Form | Ingot |

| Standard | ASTM B-23 Grade #:1 |

Babbitt Alloy Ingot is most commonly used as a thin surface layer in a complex, multi-metal structure, but its original use was as a cast-in-place bulk-bearing material. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Babbitt Alloy Ingot.

Related products: Babbitt Alloy Wire, Nitinol Sheet, Nitinol Strip

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!