AC2469 Alumina Ceramic Foam Brick

| Catalog No. | AC2469 |

| Material | Al2O3 |

| Purity | >92% |

| Heat Conductivity Coefficient | 0.85-1.2 W/(m.k) |

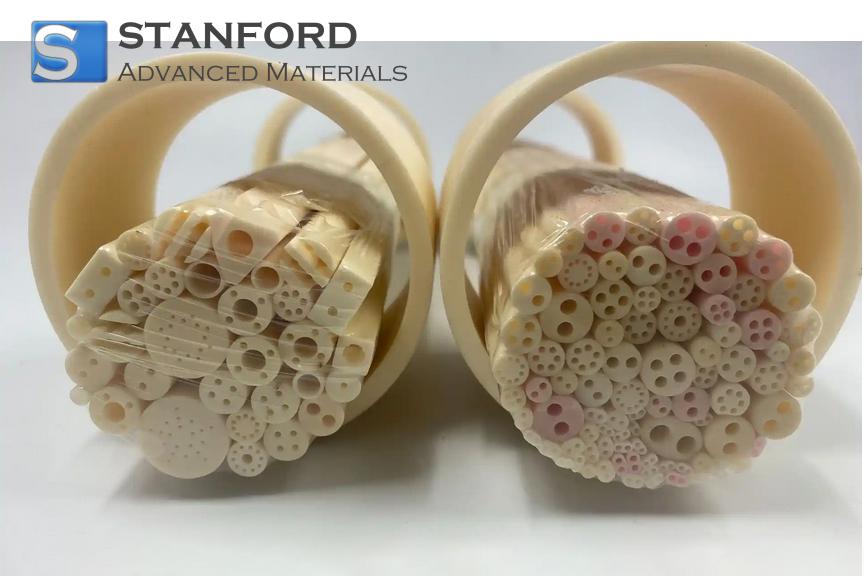

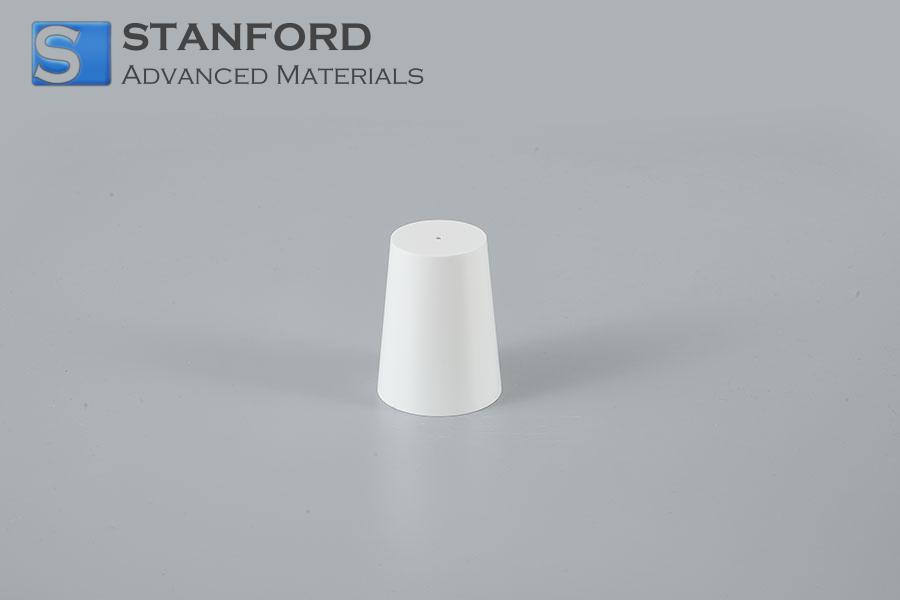

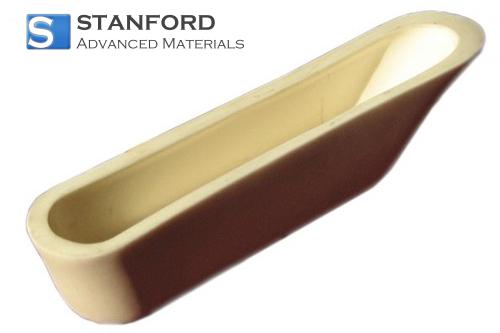

Alumina ceramic foam brick supplied in Stanford Advanced Materials is available in a variety of shapes. We have two decades’ experience in supplying high purity alumina ceramic foam bricks to fulfill most of the requirements.

Related products: Light Mullite Brick, Acid Resist Brick, High Purity Alumina Ceramic Foam Insulation.

Alumina Ceramic Foam Brick Description

Alumina ceramic foam bricks are lightweight and porous ceramic structures made from alumina-based materials. They feature a cellular or foam-like structure with interconnected pores, providing a high surface area-to-volume ratio.

It has excellent resistance to corrosion and corrosion of molten aluminum, so it can effectively remove inclusions. Due to its lightweight and low thermal conductivity, the foamed alumina has less accumulated heat energy and an excellent energy-saving effect. The precise appearance dimensions of alumina filter bricks can speed up the masonry speed and ensure high strength and stability of the masonry.

Alumina Ceramic Foam Brick Advantages

- Higher strength than refractory ceramic fiber and a lightweight ceramic brick.

- Low density

- Low thermal conductivity and linear thermal expansion coefficient.

- Great thermal shock resistance.

- Safe and rapid maintenance.

Alumina Ceramic Foam Brick Specification

|

Item |

SAMCFI-C1 |

SAMCFI-C2 |

SAMCFI-C3 |

SAMCFI-C4 |

SAMCFI-C5 |

|

Bulk Density/g·cm﹣³ |

<0.8 |

<1 |

<1.2 |

<1.4 |

<1.6 |

|

Al₂O₃ Content/% |

>99.6 |

>99.6 |

>99.6 |

>99.6 |

>99.6 |

|

Impurity % |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

|

Compressive Strength (Mpa) |

<30 |

<65 |

<72 |

<97 |

<135 |

|

Returning Line Change Rate(1800°C×12h)% |

<0.45 |

<0.4 |

<0.35 |

<0.35 |

<0.3 |

|

Heat Conductivity Coefficient W/(m.k) |

0.85 |

0.9 |

0.9 |

0.95 |

1.2 |

|

Mean Temperature 1100±25°C |

|||||

|

Working Temperature/°C |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Max. Temperature/°C |

1850 |

1850 |

1850 |

1850 |

1850 |

Alumina Ceramic Foam Brick Applications

Alumina Ceramic Foam Bricks are essential components in various industrial applications, prized for their thermal insulation properties, high-temperature resistance, and structural integrity. They are extensively used to line furnaces, kilns, and other high-temperature equipment, minimizing heat loss and maintaining stable operating temperatures in heat treatment processes and foundries handling molten metals. In foundries, these bricks protect crucibles and ladles from thermal shock and ensure consistent temperature distribution during metal casting. They also enhance thermal efficiency in heat exchangers, boilers, and industrial furnaces, reducing energy consumption and operational costs. Beyond industrial uses, alumina ceramic foam bricks contribute to fireproofing applications in construction, providing high fire resistance in structural elements and improving insulation in buildings. They are also utilized in environmental control systems and solar thermal collectors for their ability to enhance heat retention and energy efficiency. In electronics and semiconductor manufacturing, these bricks support heat management in equipment, ensuring stable operating temperatures and reliable processes. Their lightweight design, thermal stability, thermal shock resistance, and resistance to chemical corrosion make alumina ceramic foam bricks indispensable for optimizing thermal performance, durability, and safety across a range of critical industrial and environmental applications.

Alumina Ceramic Foam Brick Packing

Our Alumina Ceramic Foam Brick is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!