Alumina Tube (One End Closed) Description

Alumina Tube (One End Closed) is developed and made of Aluminum Oxide (Al2O3). Alumina, a significant ceramic oxide, is crucial in fields like electronics, medicine, and more. With a high melting point (2054℃) and chemical stability, it's used in high-temperature and contamination-free reactions. Alumina's refractory nature lets it handle up to 1750℃ in various atmospheres. It's also a valued electrical insulator, often as a substrate for integrated circuits. With its affordability, robust properties, and broad applicability, Alumina finds use across diverse industries.

Alumina Tube (One End Closed) Features

- High melting and boiling points

- good electrical insulation

- strong hardness

- Strong thermal shock resistance

- good chemical resistance

- small density and good bio-inertness

Alumina Tube (One End Closed) Specification

|

Composition

|

UNIT

|

Al95

|

Al99

|

Al997

|

|

Al2O3 Content

|

%

|

95

|

99

|

99.7

|

|

Color

|

|

White

|

Ivory

|

Ivory

|

|

Tensile Strength

|

Kpsi

|

32

|

38

|

36

|

|

Flexural Strength

|

Kpsi

|

52

|

55

|

54

|

|

Compressive Strength

|

Kpsi

|

300

|

377

|

350

|

|

Density

|

g/cc

|

3.70

|

3.90

|

3.92

|

|

Hardness

|

HV, GPa

|

13.8

|

17.2

|

18

|

|

Thermal Conductivity

|

W/(m·K)

|

25

|

30

|

30

|

|

C.O.T.E.

|

In/In℃ (x10-6)

|

7.7

|

7.8

|

7.8

|

|

Working Temperature

|

℃

|

1500

|

1650

|

1750

|

|

Dielectric Constant

|

|

9.5

|

9.7

|

9.8

|

|

Volume Resistivity (25℃)

|

Ohm-cm

|

>1014

|

>1014

|

>1014

|

Alumina Tube (One End Closed) Application

1. Thermocouple Protection: Alumina tubes are commonly used to protect thermocouples from harsh environments. The closed end of the tube can house the sensitive thermocouple tip, shielding it from corrosive gases, molten metals, and high temperatures.

2. Furnace Tubes: These tubes are used in high-temperature furnaces and kilns as reaction vessels or protective containers for samples during heat treatments, sintering, or melting processes.

3. Gas Diffusion: In chemical processing and research, alumina tubes with one end closed can be used for gas diffusion experiments. They allow controlled introduction and reaction of gases within the tube.

4. Insulation: The thermal insulating properties of alumina make these tubes useful as insulating components in high-temperature systems, helping to maintain stable temperatures and protect other components from heat.

5. Electrical Insulation: Alumina's excellent electrical insulation properties make these tubes suitable for insulating electrical wires or components, especially in high-temperature environments.

6. High-Temperature Reactions: In materials science and chemistry, alumina tubes are used for conducting high-temperature reactions, including solid-state synthesis and chemical vapor deposition.

7. Sample Containment: The closed end of the tube can serve as a container for samples undergoing various treatments in research and industrial processes, preventing contamination and ensuring purity.

8. Thermal Analysis: In thermal analysis techniques like differential thermal analysis (DTA) and thermogravimetric analysis (TGA), alumina tubes provide a stable and inert environment for precise measurements.

9. Protective Sheaths: They can serve as protective sheaths for sensors, probes, or other delicate instruments exposed to harsh conditions, extending their operational life.

10. Catalyst Supports: Alumina tubes can be used as supports for catalysts in chemical reactions, providing a high-surface-area, inert medium for catalytic processes.

11. Biomedical Applications: In biomedical research, alumina tubes can be used for high-temperature sterilization processes and as containers for biological samples subjected to heat treatments.

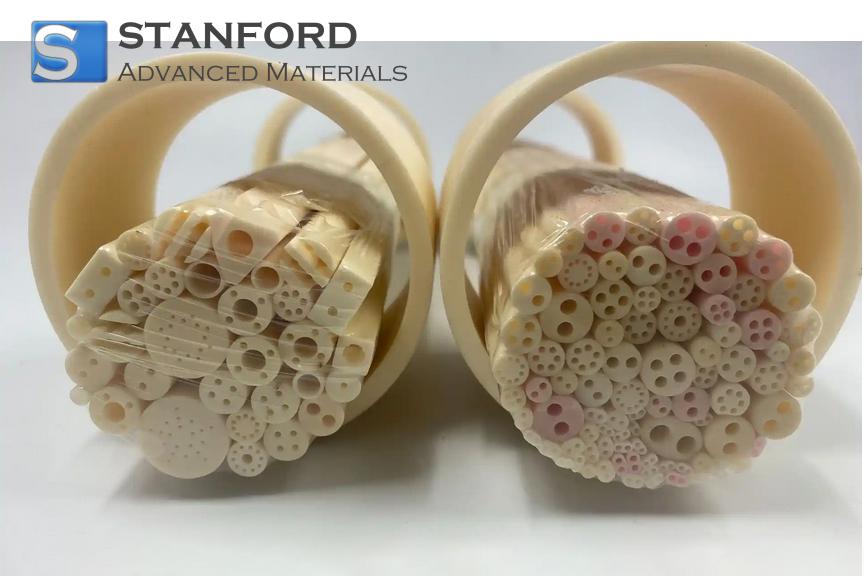

Alumina Tube (One End Closed) Packaging

Our Alumina Tube (One End Closed) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Alumina Tube (One End Closed) FAQs

Q1. What is an Alumina Dish?

An alumina dish is a laboratory and industrial vessel made from high-purity aluminum oxide (Al₂O₃). It is known for its exceptional thermal, mechanical, and chemical properties, making it suitable for high-temperature and corrosive environments.

Q2. How should Alumina Dishes be cleaned and maintained?

Cleaning: Clean with appropriate solvents and avoid using abrasive materials that could scratch the surface.

Maintenance: Handle with care to avoid mechanical damage. Store in a clean, dry environment to prevent contamination.

Sterilization: Can be sterilized using autoclaving, dry heat, or chemical disinfectants due to their thermal and chemical resistance.

Q3. What sizes and shapes are available for Alumina Dishes?

Alumina dishes come in various sizes and shapes, including standard, deep, and flat forms. Custom sizes and shapes can also be manufactured to meet specific application requirements.

.jpg)

-2.jpg)