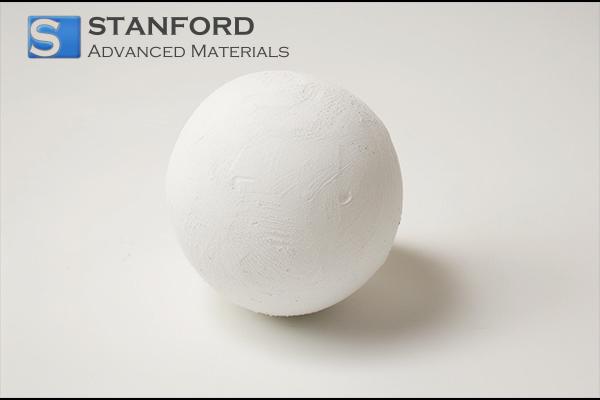

Alumina Packing Ball Descriptions

Alumina packing balls are spherical ceramic materials known for their purity, mechanical strength, and chemical inertness. They find use in various applications, such as catalyst support, heat-intensive environments, and efficient mass transfer processes due to their high thermal stability, chemical resistance, and uniformity.

Alumina Packing Ball Features:

- Purity and chemical inertness for minimal material interactions.

- Mechanical strength to withstand pressure and wear.

- Thermal stability in high-temperature environments.

- Versatility in catalyst support and efficient mass transfer applications.

- Uniform size and porosity for effective filtration and purification.

Alumina Packing Ball Specifications

|

Type

|

APB92

|

APB95A

|

APB99

|

APB995

|

|

Al2O3 (%)

|

>92

|

>95

|

>99

|

>99.5

|

|

Fe2O3 (%)

|

<0.2

|

<0.15

|

<0.1

|

<0.05

|

|

Bulk Density (g/cm3)

|

>3.20

|

>3.40

|

>3.50

|

>3.60

|

|

Packing Density(g/cm3)

|

1.80

|

1.85

|

2.00

|

2.10

|

|

Unit Compressive Strength (13mm/N)

|

>5000

|

>5500

|

>6000

|

>7000

|

|

Water Absorption(%)

|

<5

|

<5

|

<5

|

<5

|

Alumina Packing Ball Features

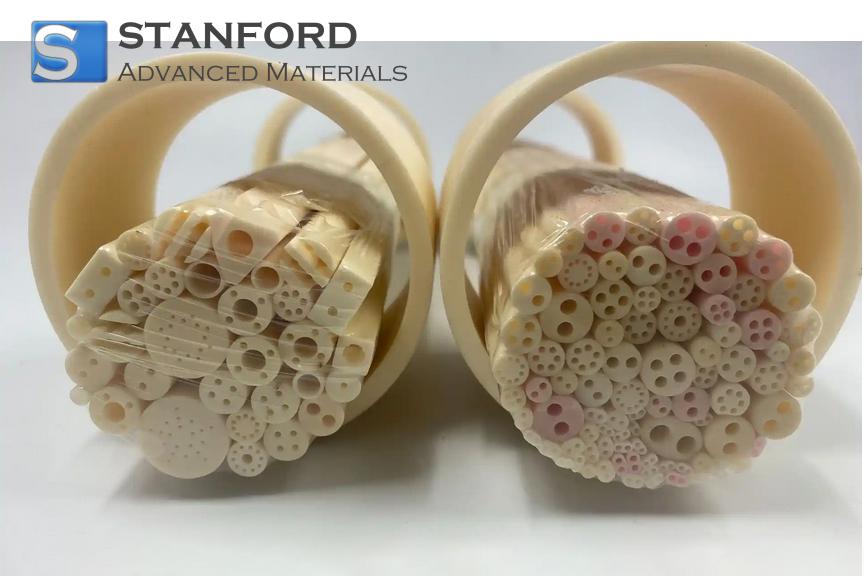

Alumina Packing Ball can withstand the corrosion of acid, alkali and other organic solvents, and the temperature change in the production process. As the support and cover material of the reactor, it can buffer the influence of liquid and gas into the reactor on the catalyst and protect the catalyst. Many Alumina Ceramic Inert Packing Balls exhibit much greater hardness than steel balls, resulting in longer life and improved reliability.

Alumina Packing Ball Applications

Alumina Packing Ball is widely used in petroleum, chemical industry fertilizer, natural gas, environmental protection and other fields, as the catalyst in the reactor cover support materials and tower filler. The main effect is to increase the distribution of gas or liquid, to support and protect low strength active catalysts.

Alumina Packing Ball Packaging

SAM’s Alumina Packing Ball is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Frequently Asked Questions (FAQ)

- Can Alumina Packing Balls be reused?

Yes, alumina packing balls can often be reused multiple times, provided they are not damaged or contaminated. Proper cleaning and inspection procedures may be necessary to ensure optimal performance.

- Can Alumina Packing Balls be customized for specific applications?

Yes, Alumina Packing Balls can be customized in terms of alumina purity, size, composition, and other specifications to meet the specific requirements of different applications.

- How do you handle Alumina Packing Balls?

Alumina Packing Balls should be handled with care to prevent damage, particularly during transportation, storage, and installation. Proper cleaning and inspection procedures should be followed to ensure optimal performance.