Alumina Grinding Ball (Dry Grinding) Descriptions

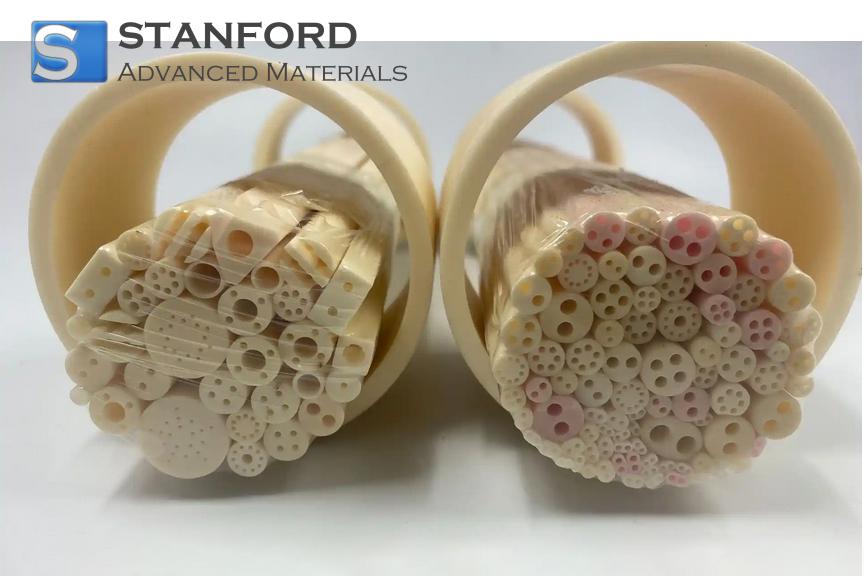

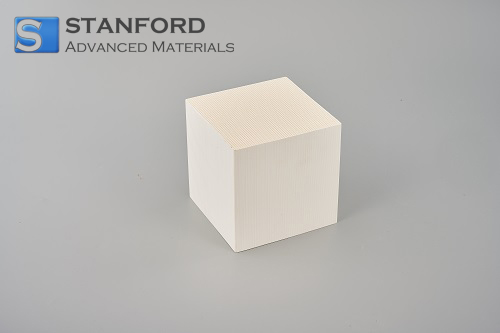

Alumina Grinding Balls (for Dry Grinding) serve as abrasive media, enabling swift and accurate refinement of ceramic raw materials and glaze substances. These balls are fabricated using isostatic pressure molding, enhancing grinding efficiency. Their design aims to minimize media loss during fine crushing operations in equipment like ball mills, can-type mills, and vibration mills. They outperform regular ball stones and natural cobblestones significantly in this capacity.

Alumina Grinding Ball (Dry Grinding) Specifications

|

Type

|

AGBD75

|

AGBD92

|

AGBD95

|

|

Al2O3(%)

|

>75

|

>92

|

>95

|

|

Bulk Density (g/cm3)

|

>3.20

|

>3.60

|

>3.65

|

|

Hardness (mohs)

|

7.5

|

9

|

9

|

|

Wear Loss(%)

|

<0.015

|

<0.015

|

<0.012

|

|

Size

|

3-90mm (or customized)

|

Alumina Grinding Ball (Dry Grinding) Features

This is a high-quality alumina grinding balls product that's lighter than steel balls, and at the same time, much harder than them (Rockwell hardness for normal alumina balls is as high as 78). Alumina balls is a small, non-maqnetic electrical insulator that easily overcomes heat (up to 1000°C), acid, alkali, corrosion, abrasion, rust, and unlubricated rollsIn addition, alumina balls keep the ball mills from harm by elevating their utilizable volume, which extends their lifespan considerably.

Alumina Grinding Ball (Dry Grinding) Applications

Alumina grinding balls are widely used in the grinding and processing of raw materials in industries such as white cement, minerals, ceramics, electronic materials, magnetics materials, and coatings and paints. Alumina ball is a high-quality grinding medium. In the building ceramic industry, the wear efficiency of alumina ceramic grinding balls is higher than that of natural flint and pebbles.

Alumina Grinding Ball (Dry Grinding) Packaging

SAM’s Alumina Grinding Ball (Dry Grinding) is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Frequently Asked Questions (FAQ)

- Can Alumina Grinding Balls be reused?

Yes, Alumina Grinding Balls can often be reused multiple times, provided they are not damaged or contaminated. Proper cleaning and inspection procedures may be necessary to ensure optimal performance.

- Can Alumina Grinding Balls be customized for specific applications?

Yes, Alumina Grinding Balls can be customized in terms of alumina purity, size, composition, and other specifications to meet the specific requirements of different applications.

- How do you handle Alumina Grinding Balls?

Alumina Grinding Balls should be handled with care to prevent damage, particularly during transportation, storage, and installation. Proper cleaning and inspection procedures should be followed to ensure optimal performance.