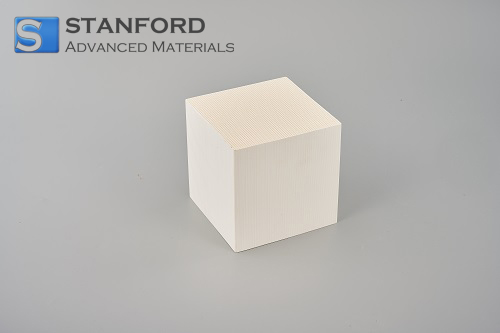

Zirconia Toughened Alumina (ZTA) Rectangular Crucible Description

Zirconia Toughened Alumina (ZTA) Rectangular Crucible is a composite ceramic with excellent mechanical properties. It is produced by the addition of Zirconia to the main Alumina matrix before sintering. It combines the advantages of both materials, offering superior mechanical strength and abrasion resistance. Zirconia Toughened Alumina (ZTA) is stronger and tougher than ordinary alumina ceramic, and provides high thermal shock resistance, but costs less than zirconia. Additionally, ZTA crucibles exhibit a better surface finish than Alumina making them an excellent choice for bio-compatible and analytical grade applications.

Zirconia Toughened Alumina (ZTA) Rectangular Crucible Specifications

Material Technical Properties

|

Max. Operating Temperature (℃)

|

1600

|

|

Porosity %

|

<0.5

|

|

Density g/cm3

|

4.1-4.38

|

|

Thermal Conductivity at 20˚C (W/mK)

|

27

|

|

Coefficient of Thermal Expansion (10-6/℃)

|

8.3

|

|

Dielectric Strength (AC-KV/mm)

|

9.0

|

|

Dielectric Constant 1MHz

|

11.0

|

|

Compressive Strength (MPa)

|

2900

|

|

Flexural Strength (MPa)

|

450

|

Typical ZTA Conical Crucible Specification

|

Top Outside Diameter

|

20mm

|

|

Top Inside Diameter

|

13mm

|

|

Wall Thickness

|

1.5mm

|

|

Internal Height

|

10mm

|

Zirconia Toughened Alumina (ZTA) Rectangular Crucible Applications

1. High-Temperature Melting and Casting: ZTA rectangular crucibles are used in processes that involve melting and casting metals and alloys at high temperatures. Their superior toughness and resistance to thermal shock make them suitable for repeated heating and cooling cycles.

2. Chemical Processing: In chemical industries, ZTA rectangular crucibles are employed for reactions and processes involving corrosive chemicals and extreme temperatures. Their chemical inertness and corrosion resistance ensure durability and reliability in harsh chemical environments.

3. Material Synthesis: ZTA rectangular crucibles are utilized in the synthesis of advanced materials, including ceramics and composites. They provide the necessary thermal stability and mechanical strength for processes such as sintering, annealing, and calcination.

4. Laboratory Use: Research laboratories use ZTA rectangular crucibles for a variety of high-temperature experiments, such as thermal analysis, ashing, and decomposition processes. Their robust construction allows for accurate and reproducible experimental results.

5. Metallurgical Applications: ZTA rectangular crucibles find application in metallurgical processes for the melting, casting, and refining of metals and alloys. Their high thermal conductivity and resistance to chemical attack make them suitable for handling molten metals at elevated temperatures.

6. Glass Manufacturing: The glass industry utilizes ZTA rectangular crucibles for melting and shaping glass materials. Their thermal stability and resistance to thermal shock ensure reliable performance in the production of glass products.

7. Semiconductor Manufacturing: ZTA rectangular crucibles are used in semiconductor manufacturing processes, such as crystal growth and wafer processing. Their high purity and thermal stability are crucial for producing semiconductor materials with precise properties.

8. Biomedical Applications: In biomedical research and manufacturing, ZTA rectangular crucibles are used for applications requiring high purity and biocompatibility, such as in the production of dental ceramics and prosthetics.

9. Environmental Testing: ZTA rectangular crucibles are employed in environmental laboratories for testing and analyzing samples at high temperatures. Their chemical inertness and thermal stability make them suitable for studying environmental contaminants and materials.

10. Aerospace and Defense: ZTA rectangular crucibles find application in the aerospace and defense industries for applications that require materials capable of withstanding extreme conditions, including high temperatures and mechanical stress.

11. Educational Purposes: ZTA rectangular crucibles are used in educational settings for teaching materials science and engineering principles related to ceramics, high-temperature materials, and industrial applications.

Zirconia Toughened Alumina (ZTA) Rectangular Crucible Packaging

Our Zirconia Toughened Alumina (ZTA) Rectangular Crucible is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Zirconia Toughened Alumina (ZTA) Rectangular Crucible FAQs

Q1: How should ZTA Rectangular Crucibles be cleaned and maintained?

Cleaning: Clean with appropriate solvents and avoid using abrasive materials that could scratch the surface. Ultrasonic cleaning can also be used.

Maintenance: Handle with care to avoid mechanical damage. Store in a clean, dry environment to prevent contamination.

Sterilization: Can be sterilized using autoclaving, dry heat, or chemical disinfectants due to their thermal and chemical resistance.

Q2: What precautions should be taken when using ZTA Rectangular Crucibles?

Handling: Handle with care to avoid dropping or impacting the crucibles, as they can be brittle and may crack or break under mechanical stress.

Temperature Changes: Avoid rapid temperature changes to prevent thermal shock, which can cause cracking.

Chemical Compatibility: Ensure compatibility with the chemicals being used to avoid reactions that could compromise the integrity of the crucible.

Q3: Can ZTA Rectangular Crucibles be customized?

Yes, ZTA rectangular crucibles can be customized to meet specific requirements, including different sizes, shapes, and thicknesses. Customization can also include specific designs or features to accommodate unique application needs.

.jpg)