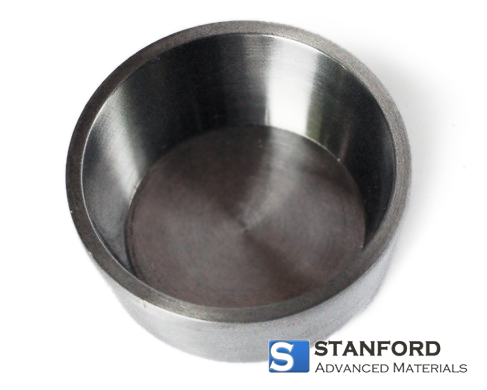

GR0191 Pyrolytic Graphite Crucible

| Catalog No. | GR0191 |

| Size | Customized |

| Material | Graphite |

| Color | Black gray |

| Shape | Crucible |

| MSDS/SDS |

Stanford Advanced Materials provide pyrolytic graphite coated and whole pyrolytic graphite crucibles. We can supply 1~200ml crucibles for whole pyrolytic graphite material and larger sizes are available for coated products. The largest available size for PG-coated products can be 350mm*600mm.

Related Products: Pyrolytic Graphite Tubes, Pyrolytic Boron Nitride Sheet (PBN Sheet)

Description of Pyrolytic Graphite Crucible

As most of the pyrolytic graphite and pyrolytic boron nitride (PBN) products are customs made, please allow 3~4 weeks of leading time. Silicon carbide CVD coating is also available. The default membrane thickness of our pyrolytic graphite products is 30um.

Pyrolytic graphite (PG) is a synthesized material created by a chemical vapor deposition process(CVD). The carbon source for this process is natural gas, such as methane. Since the purity of gas is easier to be controlled than solid graphite, the purity of pyrolytic graphite material could be extremely high. Total impurity content is usually less than 10ppm. Pyrolytic graphite could be used as a coating material for the substrate such as normal graphite. Since the PG coating is made by a CVD process with high purity gas, the surface of the pyrolytic graphite-coated products has extremely high carbon purity and strength with almost zero porosity.

If pyrolytic graphite material directly deposited on a mode, instead of a graphite substrate, pyrolytic graphite products without substrate could be obtained if the CVD process is long enough. The wall thickness of whole pyrolytic graphite products is usually 1mm. Since pure pyrolytic graphite products need more material and longer time to produce, the cost is higher than normal PG-coated graphite products.

Specifications of Pyrolytic Graphite Crucible

The following crucibles are available standard crucibles used in Stanford Advanced Material. Other custom sizes are on request.

The crucible product code is composed as follows:

Abbreviations and code:

C conical-shaped crucibles

D double-wall crucibles

Ø lip

|

|

|

Code: PG 1-12 |

Code: PG 1-14 |

|

|

|

Code: PG 1-20 |

Code: PG 5-30 |

|

|

|

Code: PG 10-22 |

Code: PG 25-50 |

|

|

|

Code: PG 35-34 |

Code: PG 25-37 |

|

|

|

Code: PG 200-102 |

|

Applications of Pyrolytic Graphite Crucible

Pyrolytic Graphite Crucibles are specialized containers known for their high thermal conductivity, exceptional chemical resistance, and ability to withstand extreme temperatures. These crucibles are extensively used in high-temperature metallurgy for melting and casting metals such as platinum and gold, and in alloy production for aerospace and advanced manufacturing. They are crucial in material science for synthesizing advanced materials and in the semiconductor industry for crystal growth, such as silicon and sapphire. In the chemical industry, Pyrolytic Graphite Crucibles handle high-temperature and corrosive reactions, while in glass manufacturing, they are used for melting glass due to their thermal stability. Additionally, they find applications in the nuclear industry for processing nuclear materials and in jewelry and art for casting precious metals. Their combination of high-temperature tolerance, chemical inertness, and precise thermal control makes them indispensable in these demanding and high-precision fields.

Packaging of Pyrolytic Graphite Crucible

Our Pyrolytic Graphite Crucibles are carefully handled during storage and transportation to preserve the quality of our products in their original condition.

Pyrolytic Graphite Crucible FAQs

Q1: What is the maximum temperature a Pyrolytic Graphite Crucible can withstand?

A1: Pyrolytic graphite crucibles can typically withstand temperatures up to 3000°C (5432°F). They offer superior thermal stability in high-heat applications, making them suitable for the most demanding processes.

Q2: Can Pyrolytic Graphite Crucibles be used in vacuum or inert gas environments?

A2: Yes, pyrolytic graphite crucibles are ideal for use in vacuum or inert gas environments (e.g., nitrogen, argon). Their minimal outgassing and excellent chemical resistance make them well-suited for processes that require controlled atmospheres, such as semiconductor manufacturing or research experiments.

Q3: What is the lifespan of a Pyrolytic Graphite Crucible?

A3: The lifespan of a pyrolytic graphite crucible depends on factors such as the temperature used, the materials processed, and the operating conditions. Under normal usage in high-temperature environments, a pyrolytic graphite crucible can last for several years. Proper care, such as avoiding thermal shock and ensuring proper handling, can help extend its life.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!