Case Study: Elevating Aerospace Excellence with Titanium 6242 Alloy

Aerospace Manufacturing Challenge

The aerospace industry faces the challenge of striking a delicate balance between structural integrity, fuel efficiency, and overall weight. Traditional materials often fall short of meeting these demands, prompting researchers to explore advanced alloys. Yet, titanium alloys have gained significant traction in recent years due to their unique properties.

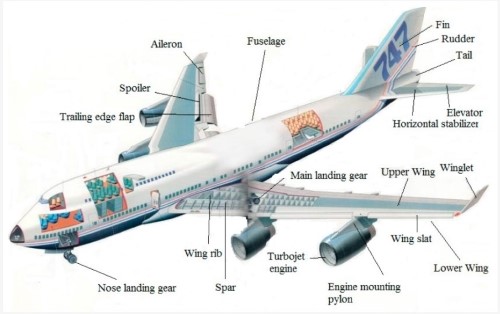

Figure 1. Aircraft Components

Innovative Titanium 6242 Alloy for Aerospace

Titanium 6242 has become a prime candidate for aerospace applications. Titanium 6242 (TI-6Al-2Sn-4Zr-2Mo-Si) is a medium-strength titanium alloy with aluminum. It offers an exceptional strength-to-weight ratio and corrosion resistance. This alloy also exhibits excellent strength, fatigue resistance, and damage tolerance, making it ideal for load-carrying structures in aircraft. Additionally, the alloy's corrosion resistance ensures longevity and durability in harsh environments.

Figure 2. Titanium 6242 Alloy

Thanks to these remarkable properties, Titanium 6242 Alloy has found extensive applications in the aerospace industry.

- Aircraft Components: Titanium 6242 is used in the manufacturing of critical aircraft components, such as landing gear, wing structures, fuselage parts, and engine components. Its high strength-to-weight ratio and exceptional fatigue resistance make it suitable for supporting structural integrity and ensuring aircraft safety.

- Aerospace Fasteners: The alloy is employed in the production of aerospace fasteners, such as bolts, screws, and nuts. These fasteners are crucial for securely holding aircraft components together and ensuring their reliability under extreme operating conditions.

- Jet Engine Components: Titanium 6242 is utilized in the construction of jet engine components due to its ability to withstand high temperatures and resist corrosion in harsh environments within the engine. It contributes to improved engine efficiency, reducing fuel consumption and emissions.

- Aerospace Propellers: The alloy is employed in aerospace propellers for both manned and unmanned aerial vehicles. Its lightweight and high-strength properties contribute to enhanced performance and fuel efficiency of the propellers.

- Structural Components: The alloy is used in various structural components throughout the aircraft, such as bulkheads, frames, and spars. Its strength and corrosion resistance enhance the overall integrity and longevity of the aircraft structure.

- Aerospace Springs: Titanium 6242 Alloy is employed in the manufacturing of springs used in various aerospace applications. Its high strength allows for the efficient absorption and release of energy in critical aerospace systems.

Related reading: Titanium Used in the Aerospace Industry

The Results

Overall, the application of Titanium 6242 Alloy in the aerospace industry is pivotal. Its combination of high strength, corrosion resistance, and superior fatigue properties provides lightweight yet robust solutions that enhance the performance, safety, and efficiency of aircraft. As aerospace manufacturers continue to seek innovative solutions, Titanium 6242 remains at the forefront, revolutionizing aerospace manufacturing and driving the industry toward new heights of excellence.

Stanford Advanced Materials (SAM) offer top-quality titanium alloys with exceptional purity and tailored material features. Customized shapes and component ratios are also available. Send us an inquiry if you are interested.

Reference:

[1] Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals 2019, 9, 662. https://doi.org/10.3390/met9060662