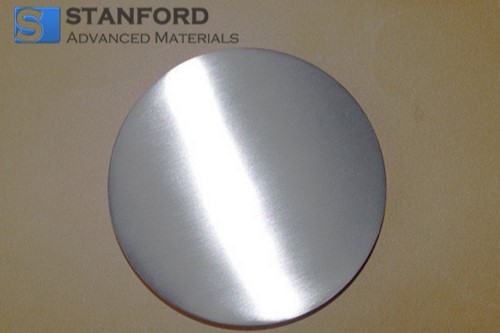

Tantalum Tungsten Disc Description

Tantalum Tungsten Disc possesses a high melting point, enabling it to maintain its structural integrity and performance even under extremely high temperatures. This thermal stability makes it suitable for use in high-temperature environments, such as in aerospace engines or nuclear reactors. The disc exhibits exceptional resistance to corrosion from various chemical agents, acids, and alkalis. This property ensures its durability and longevity, even in harsh and corrosive environments. Tantalum Tungsten Disc boasts high hardness, strength, and toughness, making it suitable for applications that require strong and durable materials. Its mechanical properties allow it to withstand high loads and stresses, maintaining its shape and functionality under extreme conditions. The disc exhibits good electrical and thermal conductivity, making it suitable for use in electronic devices and high-temperature applications where efficient heat dissipation is crucial. In nuclear applications, Tantalum Tungsten Disc demonstrates excellent resistance to radiation, maintaining its properties and performance even after exposure to high-energy radiation. The material also exhibits good biocompatibility, making it a potential candidate for medical applications such as implants or surgical instruments where material compatibility with human tissue is essential.

Tantalum Tungsten Disc Specification

Condition: Annealed

|

Product

|

Tantalum Tungsten Disc

|

|

Size

|

Diameter: 1" -10",

Thickness: 0.04" - 10"

|

|

Material

|

R05255 (Ta10W), R05252 (Ta2.5W)

|

|

Standard

|

ASTM B708-2001

|

|

Purity

|

≥99.95% or 99.99%

|

Chemical Composition

| Element |

R05255

(Ta10W)

(%,Max) |

R05252

(Ta2.5W)

(%,Max) |

| C |

0.01 |

0.01 |

| O |

0.015 |

0.015 |

| N |

0.01 |

0.01 |

| H |

0.0015 |

0.0015 |

| Fe |

0.01 |

0.01 |

| Mo |

0.02 |

0.02 |

| Nb |

0.1 |

0.5 |

| Ni |

0.01 |

0.01 |

| Si |

0.005 |

0.005 |

| Ti |

0.01 |

0.01 |

| W |

9.0–11.0 |

2.0–3.5 |

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, Ta-W alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, Ta-W alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, Ta-Nb alloy, 60 % tantalum, 40 % nobium, electron-beam furnace or vacuum-arc melt.

Tantalum Tungsten Disc Application

Due to its extremely high melting point, excellent thermal stability and mechanical strength, Tantalum Tungsten Disc is often used in the manufacture of high-temperature components in aerospace vehicles, such as nozzles and combustion chambers of engines. Under this extremely high temperature and high-pressure environments, it can maintain stable performance and ensure the normal operation of the aircraft. Due to its excellent radiation resistance, Tantalum Tungsten Disc plays an important role in the construction and operation of nuclear reactors. It can be used as a structural material for reactors, resisting the erosion of nuclear radiation and ensuring the safe and stable operation of nuclear facilities. Tantalum Tungsten Disc has good electrical and thermal conductivity, which makes it take its place in the manufacture of electronic components and semiconductor devices. It can be used as an electrode material in the manufacture of electronic components such as capacitors and resistors, or as a heat dissipation material to improve the stability and reliability of equipment. Due to its biocompatibility, Tantalum Tungsten Disc is also used in the medical field. It can be used in the manufacture of medical devices and implants, such as scalpels and dental implants. In addition, due to its corrosion resistance and stability, it can also be used to manufacture radiation shielding materials for medical devices.

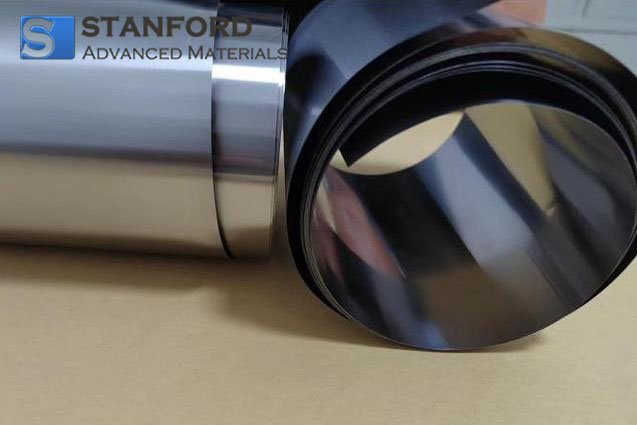

Tantalum Tungsten Disc Packaging

Our tantalum tungsten disc is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

FAQs

1 What are the benefits of using Tantalum Tungsten Discs (Ta-W Disc)?

The main benefits of Tantalum Tungsten Discs include superior heat resistance, corrosion resistance, and mechanical strength. They are ideal for applications in which the material is exposed to extreme temperatures, radiation, and chemicals, providing durability and long-lasting performance in tough conditions.

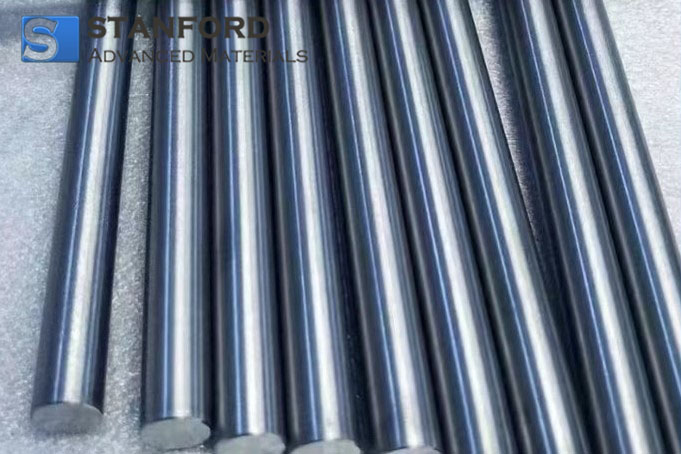

2 How are Tantalum Tungsten Discs (Ta-W Disc) manufactured?

Tantalum Tungsten Discs are typically manufactured through processes such as sintering, precision forging, and machining. The discs are shaped to the required diameter and thickness, followed by further processing to ensure the desired mechanical properties and high purity for specific industrial applications.

3. Are Tantalum Tungsten Discs resistant to corrosion?

Yes, Tantalum Tungsten Discs are highly resistant to corrosion, particularly in harsh environments, including strong acids and alkalis. The tantalum content provides excellent chemical resistance, while the tungsten adds strength and stability, making these discs ideal for chemical processing and other corrosive applications.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano

.jpg)