Sodium Hyaluronate Production Methods: Bacteria Fermentation or Rooster’s Crowns?

Introduction

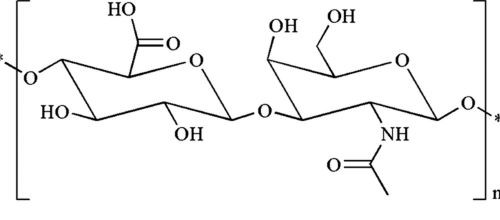

Sodium hyaluronate, the salt form of hyaluronic acid, is a naturally occurring polysaccharide. This natural material can be found in the vitreous body, dermis, synovial fluid, and other parts of the human body with hydrating and cushioning effects. It is widely used in the cosmetic and medical industries to improve skin hydration, texture, and overall appearance.

Various approaches are employed to prepare sodium hyaluronate, including sourcing from bacteria fermentation and rooster crowns. In this article, we will discuss these two production methods and their advantages and disadvantages. Hope that you can have a better understanding and select the perfect sodium hyaluronate products for your business or research.

Figure 1. Chemical Structure of HA

Sourcing from Bacteria Fermentation

--The Fermentation Process

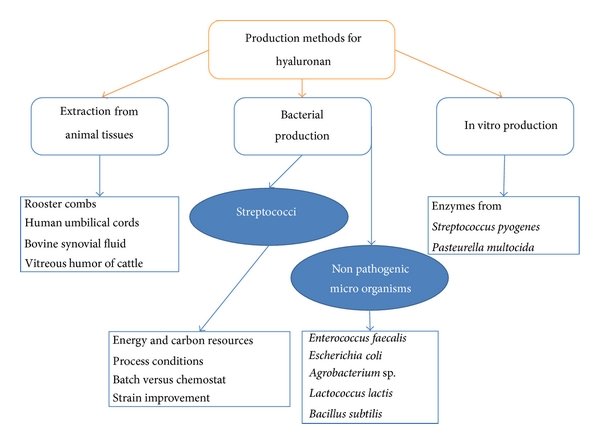

Bacteria fermentation is one of the most common methods for producing sodium hyaluronate. In this process, bacteria strains, such as Streptococcus equi or Streptococcus zooepidemicus, are cultured in a nutrient-rich environment. As the bacteria grow, they produce sodium hyaluronate, which is extracted and purified thereafter.

The process of microbial fermentation can be divided into the steps below.

- The Crude Product: The bacteria are killed after the fermentation, and precipitation with an organic solvent follows to get crude HA.

- Purification: The crude product is placed in brine and further purified.

- The Finished Product: Then, the solution is precipitated with an organic solvent and dried to obtain the finished HA product.

[2]

Figure 2. Production Methods for Sodium Hyaluronate

Related reading: Is Hyaluronic Acid Extracted from Animals?

--The Benefits of Bacteria Fermentation

The fermentation method comes with several advantages.

- Better Customization: One of the key benefits of bacteria fermentation is the ability to customize the sodium hyaluronate product to meet specific requirements. By adjusting the fermentation conditions, such as the pH, temperature, and nutrient composition, the molecular weight and viscosity can be tailored to meet the desired specifications.

- Higher Efficiency: Bacteria fermentation generates new nutrients and reduces production costs. It also increases higher extraction rates because cellulases and other enzymes promote cell rupture and the extraction of HA.

- Higher Quality: The purity of sodium hyaluronate products is much higher. More easily absorbed nano-sized small molecules such as polypeptides and polysaccharides are generated as well.

- Greener: Bacteria fermentation also offers a reliable and consistent sodium hyaluronate. Unlike other sources, such as animal-derived counterparts, this approach does not require the sacrifice of animals, making it a more ethical and sustainable option.

Related reading: How to Analyze the HA Content in the Fermentation Broth?

Sourcing from Rooster's Crowns

--The Extraction Process

Rooster's crowns, or the red combs on the top of a rooster's head, are another natural source of sodium hyaluronate. The combs are rich in connective tissue, which contains a high concentration of such a substance.

This extraction method was first used for laboratory investigations. It was abandoned for its low extraction rate, huge cost, and complicated process later.

--The Drawbacks of Extraction from Animal Tissues

Using rooster crowns as a source of sodium hyaluronate is beneficial since it has the ability to obtain a high yield. Additionally, the combs are readily available and can be harvested without harming the rooster.

However, this preparation method does have its drawbacks.

- One of the main concerns with using rooster crowns is the potential for transmitting diseases, such as avian influenza, from animals to humans.

- Another drawback is the inevitable degradation of sodium hyaluronate. That’s because different enzymes in animal tissues break down polymer chains uncontrolled in the extraction process.

- Also, the use of animal-derived sodium hyaluronate is not suitable for individuals with certain dietary restrictions, such as vegans and vegetarians.

Conclusion

In a word, both bacteria fermentation and rooster crowns offer unique benefits and drawbacks, and the choice of source will depend on the product's specific requirements and the manufacturer's ethical considerations. By selecting the appropriate sodium hyaluronate source and customizing the production process, healthcare providers and consumers can benefit from the many advantages of this versatile and effective polysaccharide.

Stanford Advanced Materials (SAM) is a leading supplier of high-purity sodium hyaluronate in the USA. A variety of medical-grade, cosmetic-grade, food-grade, and injection-grade sodium hyaluronates are available. We ensure that the sodium hyaluronate powder on our website is non-animal, Vegan, and kosher-compliant. Send us an inquiry if you are interested.

Reference:

[1] Carmen G. Boeriu, Jan Springer, Floor K. Kooy, Lambertus A. M. van den Broek, Gerrit Eggink, "Production Methods for Hyaluronan", International Journal of Carbohydrate Chemistry, vol. 2013, Article ID 624967, 14 pages, 2013. https://doi.org/10.1155/2013/624967