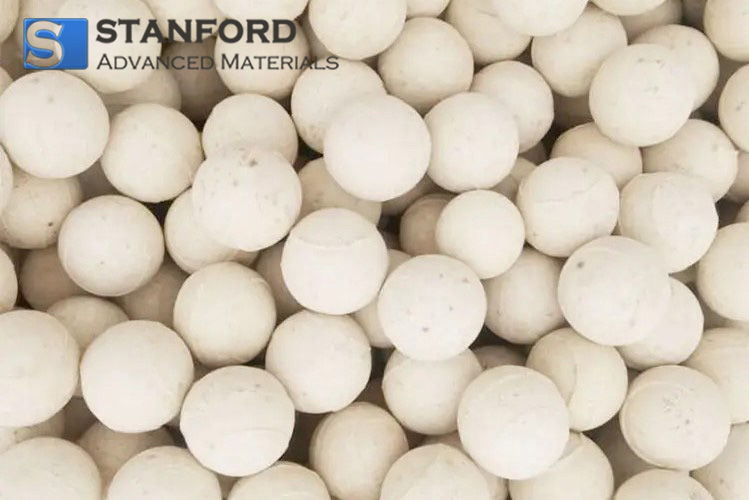

Refractory Ceramic Ball Description

Refractory Ceramic Ball is made from industrial alumina and other raw refractory materials, which are then mixed, shaped, and fired. It has the following features: 1. High strength and long service life; 2. High chemical stability; and 3. Excellent resistance to high temperatures up to 1900 degrees. It can be used as support and covering packings for catalysts in converters, reformers, desulfurizes, and methanation, and can also be used as packings in hot blast heaters and heat transformers in the iron and steel industries.

Refractory Ceramic Ball Specifications

|

Item

|

1

|

2

|

3

|

|

Al2O3, %

|

30-90

|

90-98

|

≥99

|

|

SiO2, %

|

10-70

|

0.5-5.0

|

≤0.3

|

|

Fe2O3, %

|

≥1450

|

≥1750

|

≥1850

|

|

Refractoriness, C

|

≤1

|

≤0.5

|

≤0.1

|

|

Thermal shock resistance, C

|

600

|

800

|

800

|

|

Crushing strength, N

|

100-20000 upon types and sizes

|

|

|

|

Mohs’ hardness, scal

|

≥7

|

≥8

|

≥9

|

|

Acid resistance, %

|

≥95

|

≥98

|

≥98

|

|

Alkali resistance, %

|

≥85

|

≥95

|

≥98

|

|

Bulk density, kg/m3

|

1200-1600

|

1800-2000

|

2000-2200

|

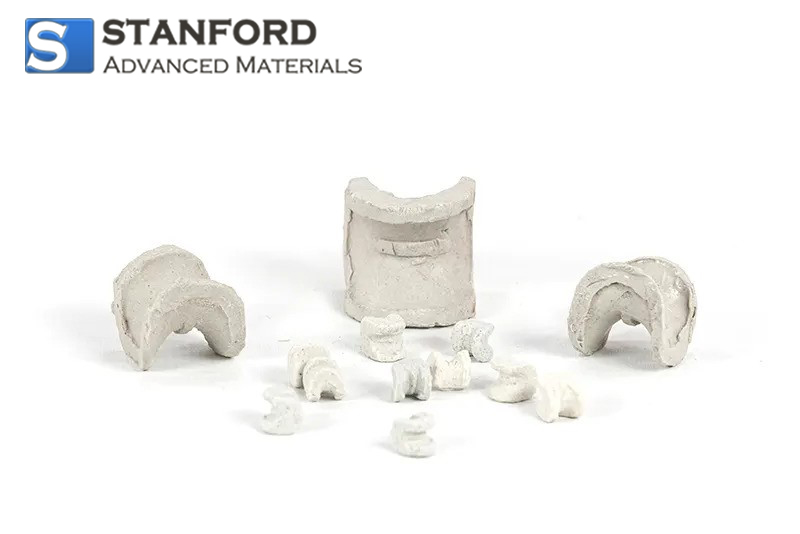

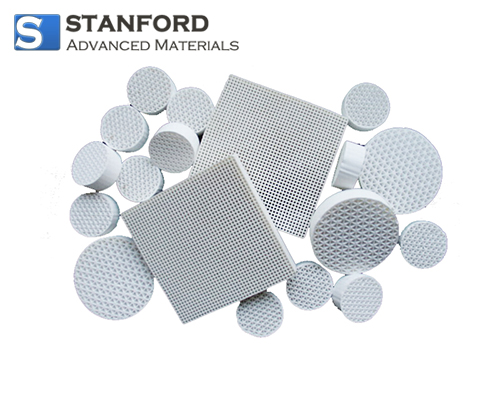

Refractory Ceramic Ball Applications

It can be used as support and covering packings for catalysts in converters, reformers, desulfurizes, and methanation, and can also be used as packings in hot blast heaters and heat transformers in the iron and steel industries.

Refractory Ceramic Ball Packaging

Our Refractory Ceramic Balls are carefully handled during storage and transportation to preserve the quality of our product in its original condition.