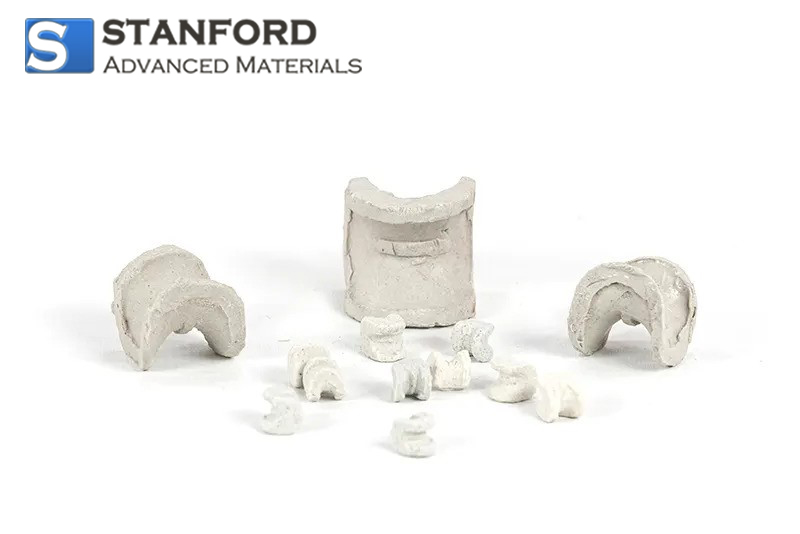

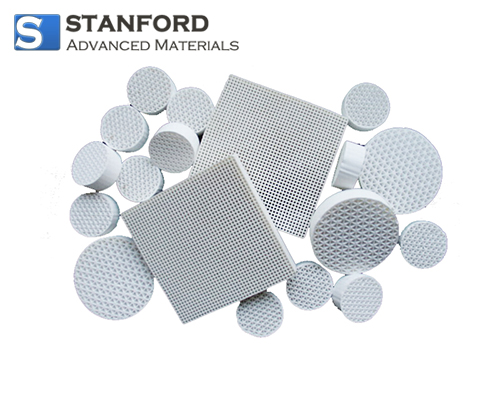

Heat Storage Ceramic Ball Description

Heat Storage Ceramic Ball has features of high strength, low abrasion loss, large heat capacity, and thermal conductivity resulting in efficient heat storage performance, excellent resistance to high temperature, and thermal shock. It is widely used in recuperators in the air separation process and also used to pre-heat the gas and the air in coal gas heating furnaces in iron & steel plants.

Heat Storage Ceramic Ball Specifications

|

Type

Item

|

1

|

2

|

|

Chemical Composition, %

|

Al2O3

|

20-30

|

60-65

|

|

SiO2±Al2O3

|

≥90

|

≥90

|

|

Fe2O3

|

≤1

|

≤1.5

|

|

Size, mm

|

φ10-12/φ12-14

|

φ16-18/φ20-25

|

|

Heat capacity, J/kg.k

|

≥836

|

≥1000

|

|

Thermal conductivity, w/mk

|

2.6-2.9

|

|

|

Thermal shock resistance, ℃

|

20-800

|

20-1000

|

|

Refractoriness, ℃

|

1550

|

1750

|

|

Abrasion loss, %

|

≤0.1

|

≤0.1

|

|

Mohs’ hardness, Scal

|

≥6.5

|

≥6.5

|

|

Crushing strength, N

|

800-1200

|

1800-3200

|

|

Bulk density, kg/m3

|

1300-1400

|

1500-1600

|

Heat Storage Ceramic Ball Applications

It is widely used in recuperators in the air separation process and also used to pre-heat the gas and the air in coal gas heating furnaces in iron & steel plants.

Heat Storage Ceramic Ball Packaging

Our Heat Storage Ceramic Balls are carefully handled during storage and transportation to preserve the quality of our product in its original condition.