- Products

- Categories

- Blog

- Podcast

- Application

- Document

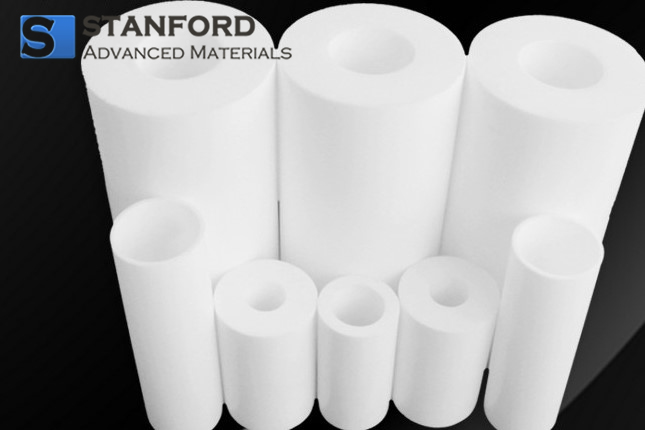

TF1806 PTFE Tube

| Catalog No. | TF1806 |

| Diameter | 30-525 mm |

| Type | Extruded tube/ Molded tube |

| Wall thickness | 1.5-95 mm |

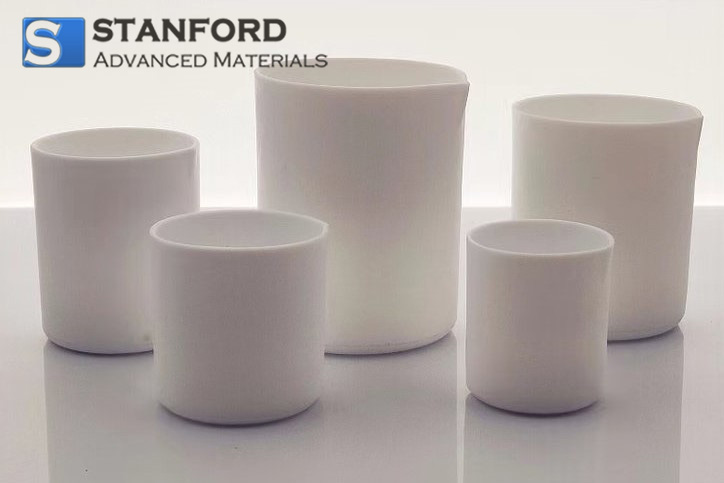

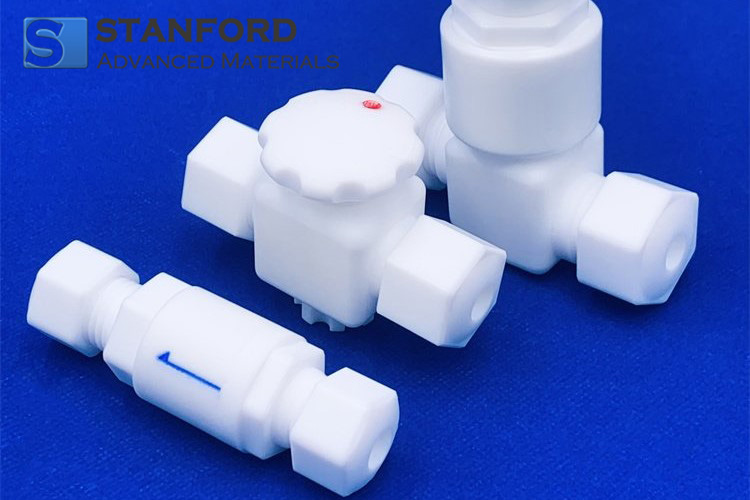

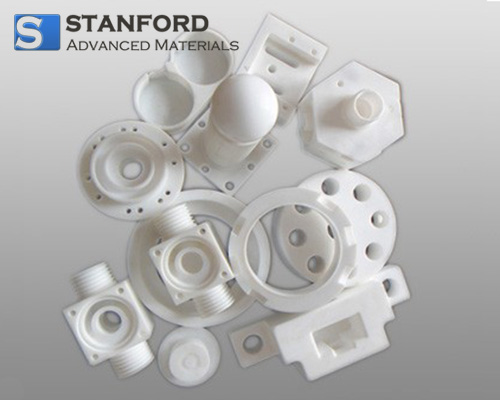

Stanford Advanced Materials (SAM) is a trusted supplier and manufacturer of PTFE Rods, PTFE Tube and PTFE Plate in various shapes and sizes. Other customized PTFE products are also available upon your requirements.

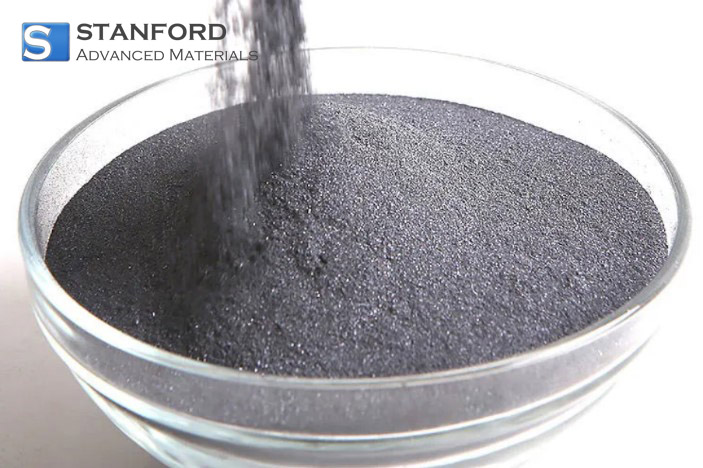

Related Products: PTFE Rod, PTFE Powder, PTFE Plate/Sheet/Board

INQUIRY

Add to Inquiry List

Description

Specification

Video

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!