Precious Metal Catalysts for the Petroleum Sector

Introduction

Precious metals, such as platinum, palladium, rhodium, and gold, are commonly used in catalysts due to their unique physical and chemical properties. These metals have a high resistance to corrosion, high melting points, and excellent catalytic activity. They are also able to withstand harsh environments and maintain their catalytic properties for extended periods.

Thanks to these desirable features, precious metal catalysts have become an integral part of the petroleum industry. They are utilized in the refining of crude oil into usable products like gasoline, diesel, and jet fuel, as they help speed up the refining process, while also increasing yield and improving product quality. In this article, we will explore the different types of precious metal catalysts used in the petroleum sector and their benefits. Hope that you can have a better understanding of their characteristics and applications.

Figure 1. Precious Metal Catalysts

Types of Precious Metal Catalysts Used in the Petroleum Industry

There is a variety of precious metal catalysts employed in the petroleum sector. The main precious metal catalyst and their applications are listed below.

- Platinum Catalysts: Platinum is widely used as a catalyst in the petroleum industry, particularly in the reforming process. Platinum catalysts are typically applied to convert low-octane naphtha into high-octane gasoline. They are also used in the isomerization process, which involves converting linear hydrocarbons into their branched isomers.

- Palladium Catalysts: Palladium is a common catalyst in the petroleum industry, especially in the hydrogenation process. Palladium catalysts are utilized to convert unsaturated hydrocarbons into saturated hydrocarbons, a critical process in the production of diesel fuel.

- Ruthenium Catalysts: Ruthenium catalysts are utilized in the petroleum industry for the production of ethylene, which is a key building block for the production of many petrochemicals, including plastics, synthetic rubber, and resins.

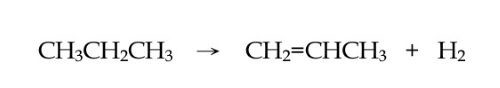

- Other Precious Metal Catalysts: Precious metal catalysts are also employed for the dehydrogenation of propylene (see Figure 2) and the production of highly pure cyclohexane.

Figure 2. Dehydrogenation of Propane with Pt/Al2O3

Benefits of Precious Metal Catalysts in the Petroleum Industry

In these ways, precious metal catalysts find applications in the petroleum industry with countless advantages. They not only improve the efficiency of chemical reactions but also reduce costs and environmental impact. Some other benefits include:

- Improved Efficiency: Precious metal catalysts promote the efficiency of the refining process by speeding up the reaction rates. This leads to an increase in productivity, which in turn leads to higher profits for petroleum companies.

- Improved Yield: Precious metal catalysts can help increase the yield of refined products, such as gasoline and diesel fuel. This can be achieved by converting low-quality feedstocks into high-quality products.

- Improved Quality: These catalysts can also improve the quality of the refined product. For instance, they help to remove impurities, such as sulfur and nitrogen, from the feedstocks, resulting in cleaner and more environmentally friendly products.

- Longer Catalyst Life: Precious metal catalysts typically have a longer life span than traditional catalysts, which means they need to be replaced less frequently. So, lots of costs can be saved for petroleum companies.

- Better Selectivity: Precious metal catalysts are highly selective. Namely, they can reduce unwanted byproducts and increase the purity of the final products consequently. For example, palladium catalysts are used in a variety of reactions, such as hydrogenation, cross-coupling, and carboxylation, due to their better selective performance. Similarly, the platinum catalyst is applied to form cyclohexane selectively.

Related reading: Advantages of Precious Metal Catalysts

Conclusion

Precious metal catalysts have revolutionized the petroleum industry by increasing efficiency and selectivity, improving yield and quality, and extending the life of catalysts. Platinum, palladium, and ruthenium are some of the most commonly used precious metal catalysts in the industry. As the demand for cleaner and more efficient fuels continues to grow, such catalysts will continue to play a critical role in the petroleum refining process.

Stanford Advanced Materials (SAM) has rich experience in the manufacture and sale of various precious metal catalysts. We offer precious metal crucibles, precious metal wires, and other precious metal products at reasonable prices. Send us an inquiry if you are interested.