Case Study: Powering the Future of Solar Energy with Cadmium Telluride

Introduction

Cadmium Telluride (CdTe) has emerged as a pivotal player in the realm of solar energy applications. Recognized for its exceptional photovoltaic properties, CdTe holds the promise of efficient sunlight-to-electricity conversion, offering an avenue toward cost-effective and scalable renewable energy solutions. This article is going to discuss the multifaceted role of CdTe in solar technology, exploring its merits, challenges, and significance in shaping the renewable energy landscape.

Figure 1. Solar Panels

Understanding Cadmium Telluride

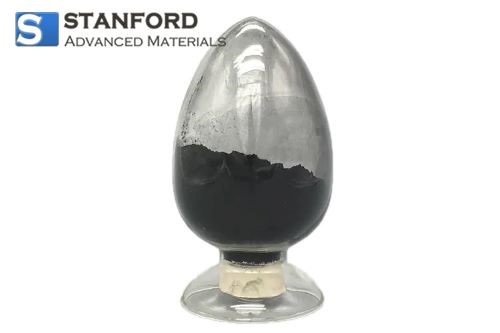

Cadmium Telluride (CdTe) is a compound semiconductor material that has gained significant attention as a photovoltaic material for solar energy applications. It is used in the manufacturing of thin-film solar cells to convert sunlight into electricity. This thin-film structure not only allows for efficient light absorption but also reduces material usage compared to traditional silicon solar cells.

Figure 2. Cadmium Telluride Powder

Benefits of Cadmium Telluride Solar Cells

CdTe Solar Cells have gained popularity due to their efficiency, cost-effectiveness, and potential for large-scale commercial applications. Here are some key features:

Efficiency: They have achieved relatively high conversion efficiencies, which are competitive with other thin-film technologies and even some silicon-based solar cells.

Cost-Effectiveness: The production process for CdTe cells is simpler and requires less material compared to traditional silicon-based cells. This leads to lower manufacturing costs and potentially lower overall system costs for installations.

Challenges: While such solar cells have many advantages, they also face challenges. The toxicity of cadmium requires careful handling and disposal, and concerns have been raised about the potential for cadmium leakage in the event of module breakage or degradation over time.

Case Study: Cadmium Telluride for Solar Energy

--The Challenge

In its quest for high-quality Cadmium Telluride Materials in solar energy technology, a customer turned to the guidance offered by SAM. SAM, with its expertise in materials science and renewable energy applications, had put forth a series of recommendations tailored to optimizing CdTe's potential within the realm of solar energy.

--The Solution

The following specifications of Cadmium Telluride Products are recommended:

Cell Size: The choice of cell size is important for balancing efficiency, manufacturing costs, and scalability. Common CdTe Solar Cell specifications on the market include 3 inches, 4 inches, and 6 inches. Among them, the 4-inch CdTe Solar Cell has higher efficiency and lower manufacturing costs, which is suitable for large-scale production and commercial applications.

Purity: Purity is indeed a critical factor affecting solar cell efficiency. Higher purity CdTe Material allows for better charge carrier transport and reduces defects that can limit performance. A purity level of 99.99% or higher is recommended to achieve optimal conversion efficiency.

Crystal Structure: The quality of the crystal structure in CdTe Material is directly tied to the performance and lifespan of the solar cell. A well-defined crystal structure helps minimize defects and enhance the transport of charge carriers.

--The Results

These considerations highlighted the importance of material quality in CdTe Solar Cell production. Therefore, customers could get CdTe Material that maximizes efficiency, stability, and long-term performance.

Conclusion

Overall, CdTe Solar Cells offer a promising option for large-scale solar energy generation thanks to their large light absorptivity, high transfer efficiency, and perfect bandgap, which comes with high efficiency and low manufacturing costs. Stanford Advanced Materials (SAM) stands as a reliable source for an array of Cadmium Telluride Compounds. We also offer customized products. Send us an inquiry if you are interested.