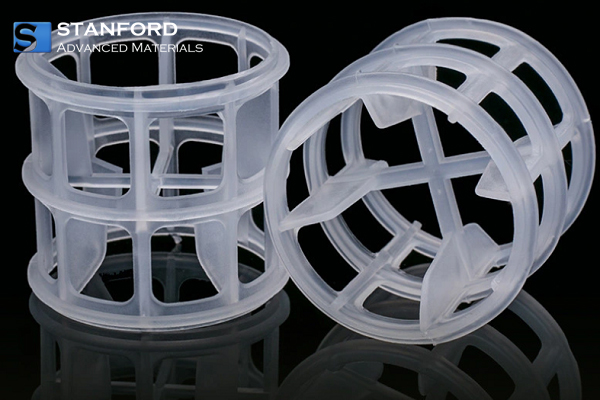

Plastic Hiflow Ring Description

Plastic Hiflow Ring is an open-structured cylindrical random packing that can consider both high machinal strength and high flow ratio. Its grid structure makes Plastic Hiflow Ring’s pore ratio 50% higher than the same size pall ring. Its bed void fraction is also larger than other pall rings. Staggered vertical bars and reinforced horizontal stripes further improve its rigidity and strength. Plastic Hiflow Ring is a random packing with a low-pressure drop, low mass-transfer unit height, small specific gravity, high mass-transfer efficiency, and high free volume.

Plastic Hiflow Ring Specifications

Physical performance

|

Material

|

PP

|

PE

|

PVC

|

CPVC

|

PVDF

|

PFA

|

|

Density (g/cm3)

|

0.96

|

0.98

|

1.7

|

1.8

|

1.8

|

2.45

|

|

Max. Operating Temperature (℃)

|

< 100

|

< 90

|

< 60

|

< 93

|

< 150

|

< 260

|

|

Compression Strength (MPa)

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

Specification

|

Size (inches)

|

1/2”

|

1”

|

1-1/2”

|

2”

|

3-1/2”

|

|

Surface Area (m2/m3)

|

260

|

210

|

140

|

100

|

73

|

|

Voidage (%)

|

91

|

92

|

94

|

94

|

96

|

|

Bulk Density (kg/m3)

|

80

|

79

|

58

|

64

|

33

|

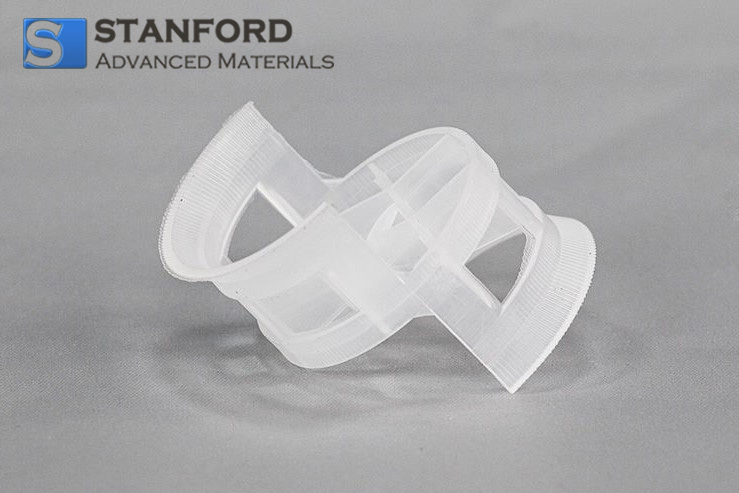

Plastic Hiflow Ring Applications

Plastic Hiflow Rings are widely used in chemical petrochemical, and refining industries such as mass transfer operations, tower internals, waste treatment, and gas-liquid contacting. Its good corrosive resistance and high durability let plastic hiflow ring be used in harsh environments.

Plastic Hiflow Ring Packaging

Our Plastic Hiflow Ring are carefully handled during storage and transportation to preserve the quality of our product in its original condition.