- Products

- Categories

- Blog

- Podcast

- Application

- Document

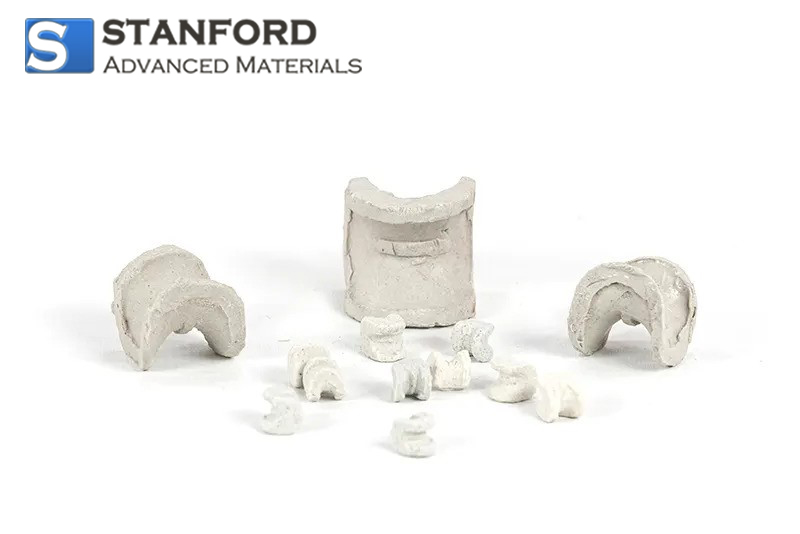

RP4622 Plastic Super Saddle Ring

| Catalog No. | RP4622 |

| Material | PE, PP, RPP, PVC, CPVC, , etc. |

| Total Life | >3 years |

| Color | White/Black |

Plastic Super Saddle Ring has excellent strength and mass transfer performance. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Random Packing.

Related products: Porcelain Berl Saddles, Porcelain Super Saddles, Plastic Intalox Saddle

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!