- Products

- Categories

- Blog

- Podcast

- Application

- Document

NK4207 Nickel-Hafnium (Ni-Hf) Master Alloy

| Catalog No. | NK4207 |

| Material | Ni, Hf |

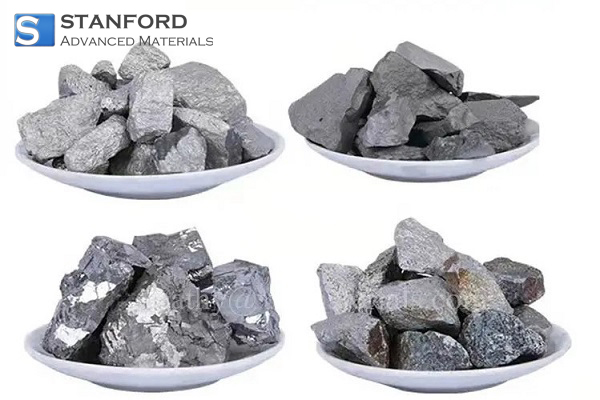

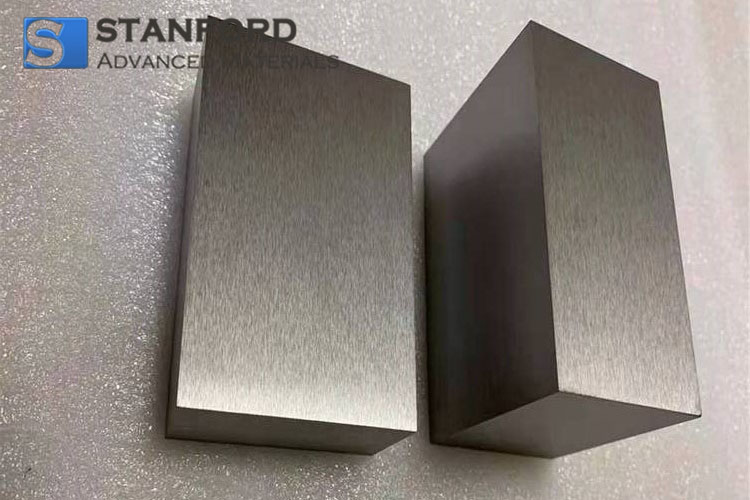

| Appearance | Gray solid |

| Content | Hafnium 30% |

Nickel-Hafnium (Ni-Hf) master alloy is a blend of nickel and hafnium, used to improve high-temperature strength, creep resistance, and grain refinement in superalloys and other advanced materials. Stanford Advanced Materials (SAM) offers high-quality Master Alloy with competitive pricing.

Related products: Aluminum Bismuth Master Alloy, Aluminum Manganese Master Alloy, Manganese Silicon Alloy Powder / MnSiFe Powder

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!