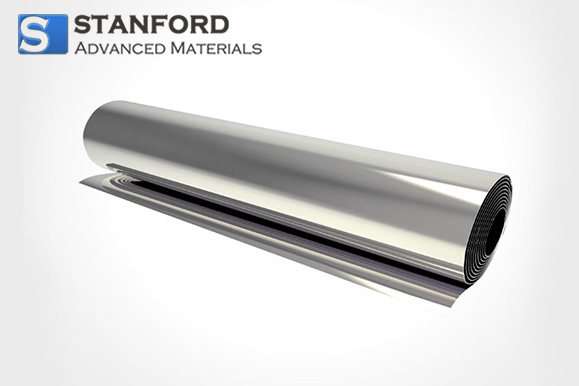

NBN0061 Niobium Nickel Alloy Sheets & Boards

| Catalog No. | NBN0061 |

| Surface | Polished |

| Size | <0.20 mm Thickness; <1000 mm Width; <50 mm Length |

| Material | Nb63Ni-A, Nb63Ni-B, Nb56Ni-A, Nb56Ni-B |

| MSDS/SDS |

Stanford Advanced Materials (SAM) has over two decades of experience in supplying high-quality Niobium Nickel Alloy Sheets & Boards at competitive prices. We are also able to customize this product per your specifications.

Related: Niobium Nickel Alloy Foil, Niobium Nickel Alloy Lumps

Niobium Nickel Alloy Sheets & Boards Description

Niobium Nickel Alloy Sheets & Boards exhibit strong resistance to a wide range of corrosive media, including strong acids and bases, allowing them to maintain their structural integrity and performance stability for long periods in harsh environments. Even at extreme temperatures, Niobium Nickel Alloy Sheets & Boards remain physically and chemically stable and are not prone to deformation or melting, thus ensuring reliable application in high temperature environments. The alloy's high strength, hardness, toughness and ductility allow it to withstand high mechanical stresses and pressures, making it suitable for a wide range of components and structures that require high strength and durability. Niobium Nickel Alloy Sheets & Boards excel in electrical and thermal conductivity, which makes them a promising choice for a wide range of applications in the fields of electronics, electrical power, and heat conduction. This makes them ideal for a wide range of applications in electronics, electricity and heat transfer. However, it should be noted that specific application scenarios and requirements may limit the purity, thickness, size, etc. of Niobium Nickel Alloy Sheets & Boards, so the selection and use of Niobium Nickel Alloy Sheets & Boards needs to be evaluated and chosen on a case-by-case basis.

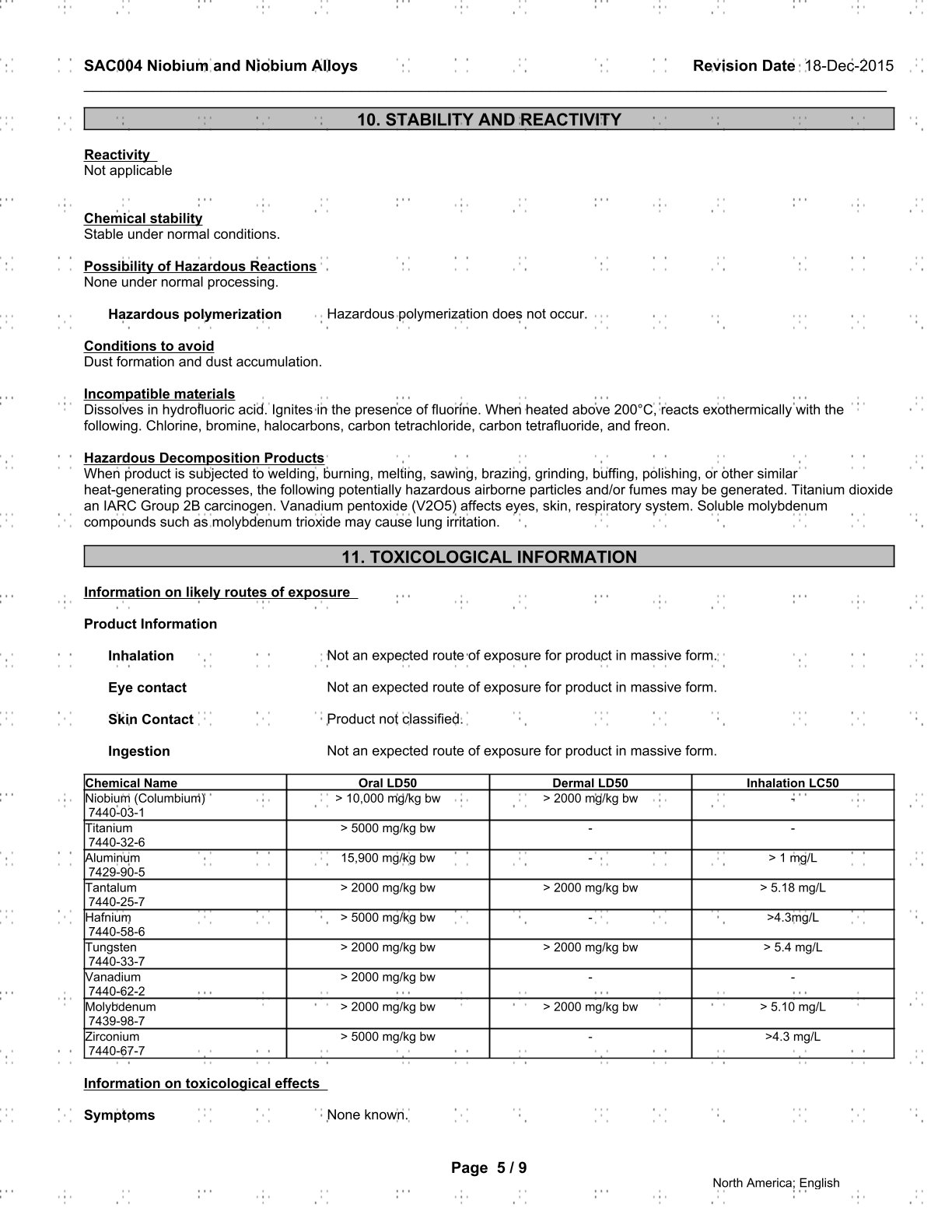

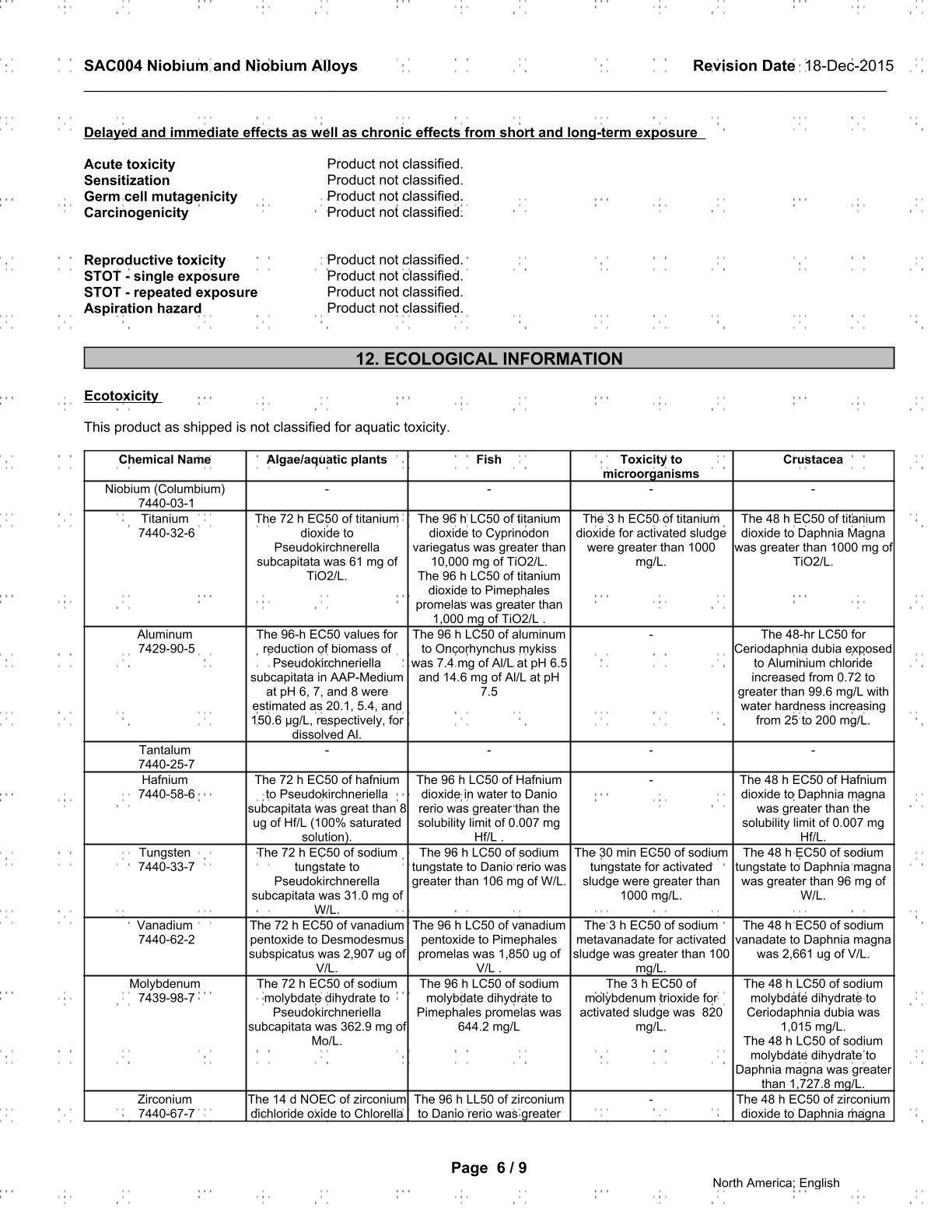

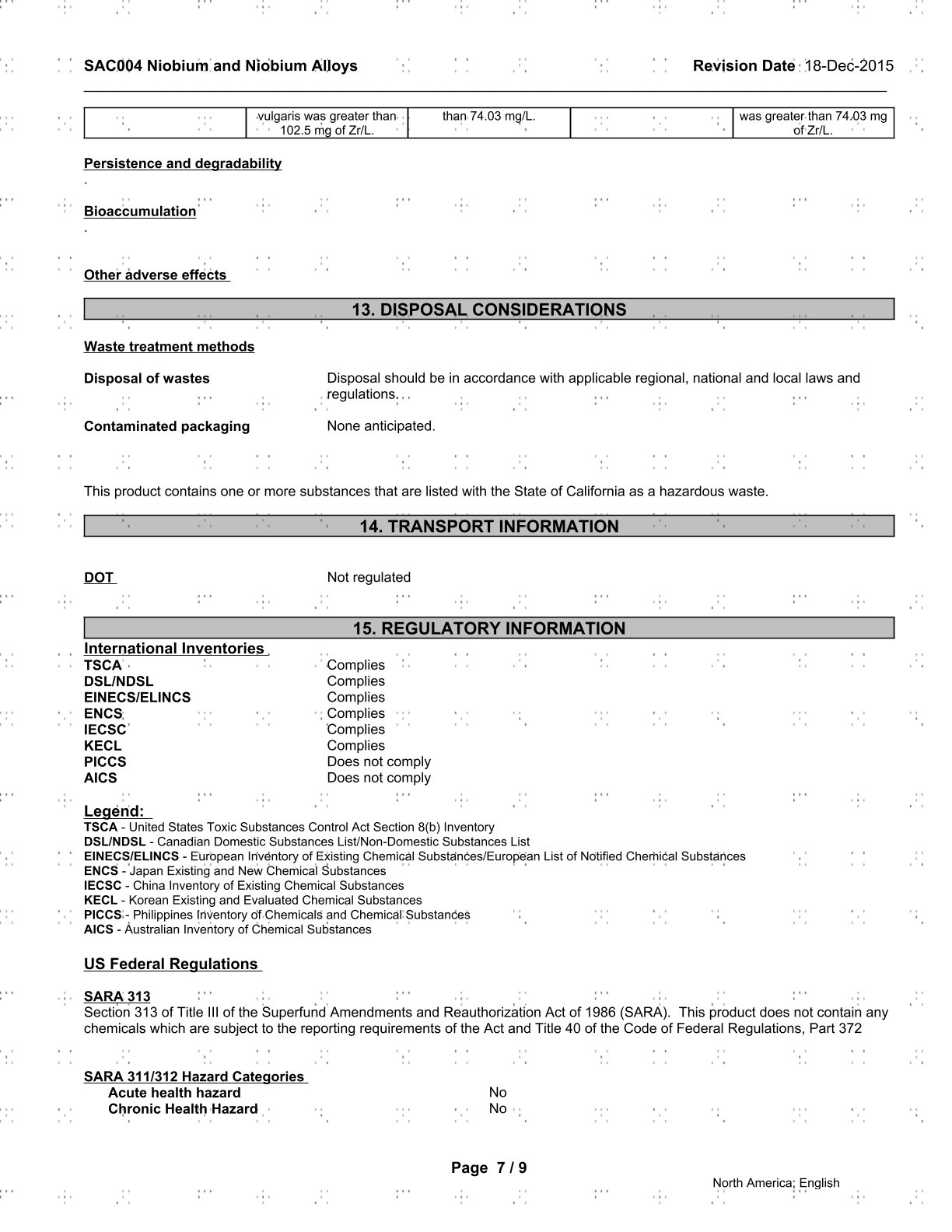

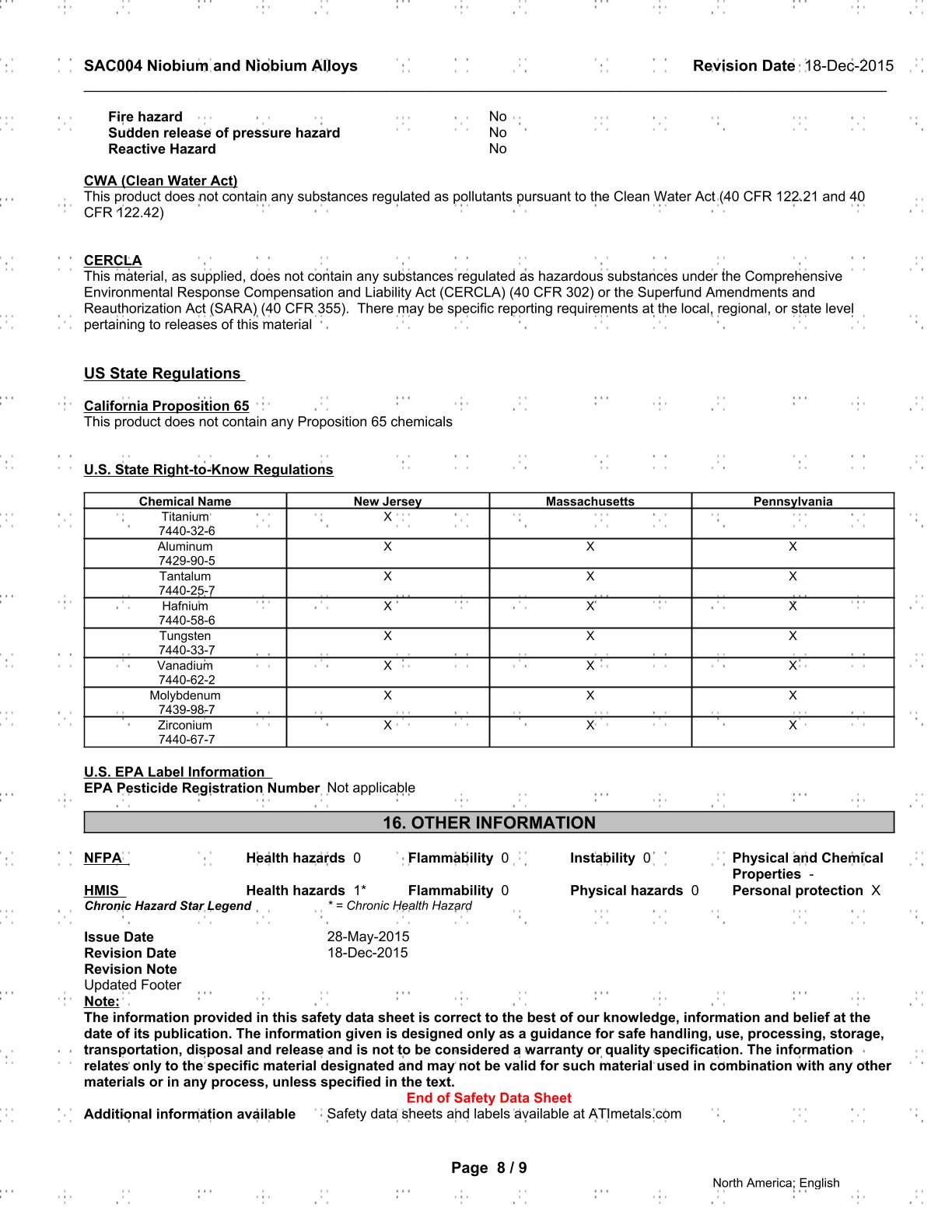

Niobium Nickel Alloy Sheets & Boards Specification

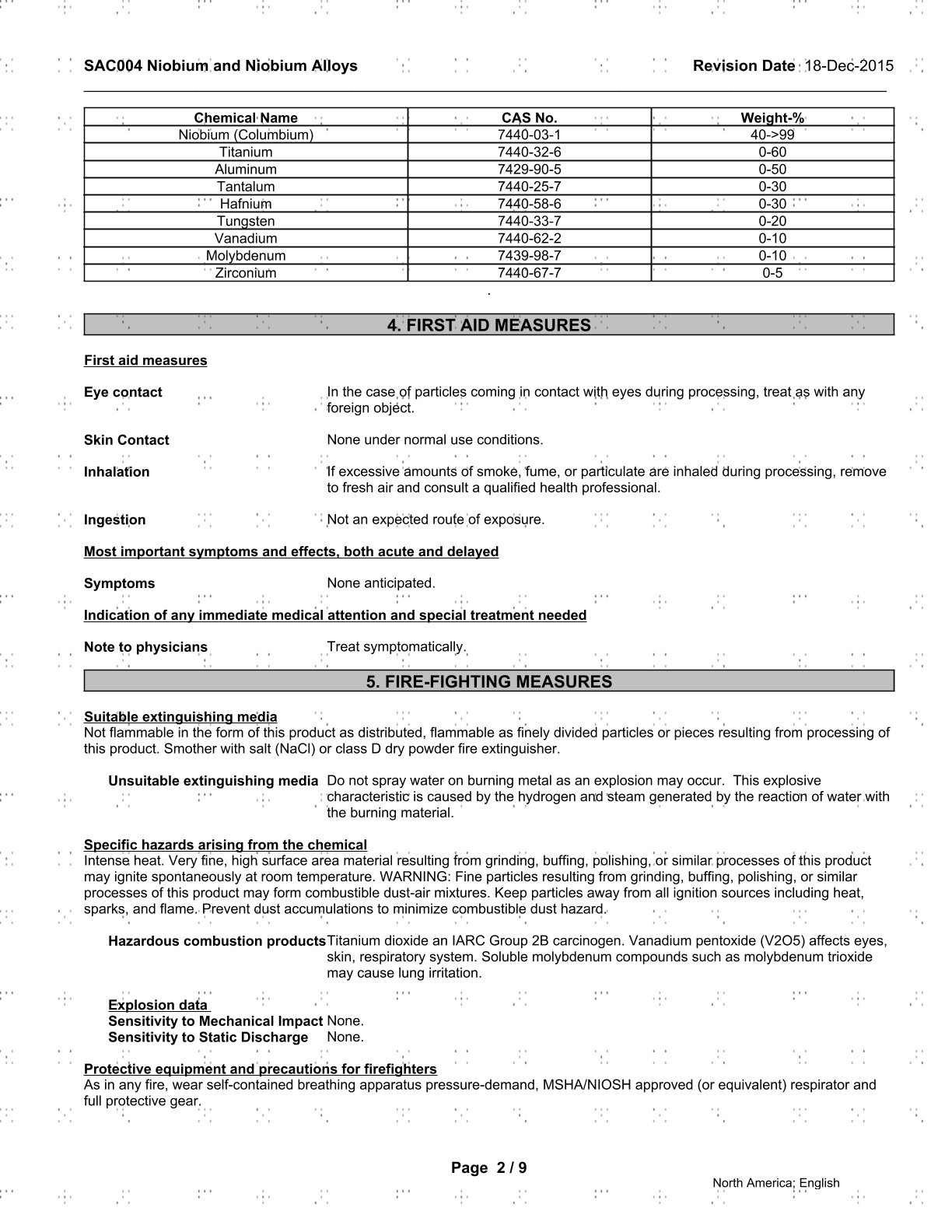

|

Item No. |

Nb63Ni-A |

Nb63Ni-B |

Nb56Ni-A |

Nb56Ni-B |

|

Nb |

≥63.0 |

≥61.0 |

≥56.0 |

≥54.0 |

|

Ni |

remainder |

remainder |

remainder |

remainder |

|

Impurities |

Concentrations (%,≤) |

|||

|

O |

0.1 |

0.2 |

0.1 |

0.2 |

|

C |

0.05 |

0.1 |

0.05 |

0.1 |

|

N |

0.05 |

0.08 |

0.05 |

0.08 |

|

H |

- |

- |

- |

- |

|

Fe |

0.5 |

0.5 |

0.5 |

0.5 |

|

Cr |

- |

- |

- |

- |

|

Si |

0.25 |

0.3 |

0.25 |

0.3 |

|

Pb |

0.005 |

0.01 |

0.005 |

0.01 |

|

Ta |

0.2 |

0.2 |

0.2 |

0.2 |

|

Cu |

- |

- |

- |

- |

|

W |

- |

- |

- |

- |

|

Mo |

- |

- |

- |

- |

|

Ti |

0.1 |

0.1 |

0.1 |

0.1 |

|

Zr |

- |

- |

- |

- |

|

Sn |

0.005 |

0.02 |

0.005 |

0.02 |

|

S |

0.01 |

0.02 |

0.01 |

0.02 |

|

Al |

1.5 |

2 |

1.5 |

2 |

|

P |

0.01 |

0.03 |

0.01 |

0.03 |

Niobium Nickel Alloy Sheets & Boards Applications

1. Aerospace: In the aerospace industry, Niobium Nickel Alloy Sheets & Boards are favored for their excellent resistance to high temperatures and corrosion. It is widely used in the manufacture of engine parts, high-temperature structural components, and other critical assemblies for airplanes and rockets. Niobium-nickel alloy sheet meets the stringent requirements of these components, which need to maintain stable performance in extreme temperatures and highly corrosive environments.

2. Nuclear: Niobium Nickel Alloy Sheets & Boards also play an important role in the nuclear industry. Due to its excellent radiation resistance and stability, it is often used to manufacture key components of nuclear reactors, such as fuel cladding and structural supports. These components are subjected to high radiation and high temperatures, and Niobium-Nickel alloy plates can keep their performance stable and ensure the safe operation of nuclear facilities.

3. Electronics Industry: Niobium Nickel Alloy Sheets & Boards are widely used in the electronics industry due to their excellent electrical conductivity and stability. It can be used to manufacture capacitors, resistors and other electronic components, which play a key role in electronic equipment and help to ensure the stable operation of the equipment.

4. Chemical industry: The corrosion resistance of Niobium Nickel Alloy Sheets & Boards gives it a broad application prospect in the chemical industry. It can be used to manufacture corrosion-resistant pipelines, valves, reactors and other equipment that need to withstand a variety of chemical substances in the chemical production process, and Niobium Nickel Alloy Sheets & Boards can provide reliable protection.

Niobium Nickel Alloy Sheets & Boards Packing

Our Niobium Nickel Alloy Sheets & Boards are carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

FAQs

Q1: What are the main applications of Niobium Nickel Alloy Sheets & Boards?

A1: Niobium Nickel alloy sheets and boards are widely used in aerospace, electronics, chemical processing, and superconducting materials. They are ideal for high strength, corrosion resistance, and excellent thermal or electrical conductivity applications.

Q2: Are these products suitable for high-temperature applications?

A2: Yes, Niobium Nickel alloys are designed for high-temperature applications, withstanding extreme heat while maintaining stability and mechanical strength.

Q3: How are the sheets and boards packaged for transportation?

A3: The sheets and boards are securely packaged with protective layers to prevent scratches or damage during shipping. They are also sealed in moisture-proof containers to maintain material integrity.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!