Low Temperature Glass Powder(550C) Description

Stanford Advanced Materials presents Low Temperature Glass Powder (550C), meticulously crafted from a blend of non-metallic oxides through a series of specialized processes including crushing, purification, grinding, and grading. This advanced sealing material boasts a low melting and sealing temperature, along with exceptional heat resistance, chemical stability, and robust mechanical strength.

Its versatility shines through as it facilitates the sealing of materials like glass, ceramics, metals, and semiconductors that are typically challenging to integrate due to compatibility issues. This characteristic makes it immensely valuable in a multitude of applications across various high-precision fields such as electric vacuum and microelectronics technology, laser and infrared technology, high-energy physics, aerospace, and beyond.

Low Temperature Glass Powder(550C) Specifications

|

Physicochemical Information

|

|

Average Particle Size D50 (μm)

|

2-10

|

|

Max. Particle Size D50 (μm)

|

<5, or customized

|

|

Mohs Hardness

|

2-7

|

|

Linear Expansion Coefficient

|

20-100 1/K

|

|

Conductivity

|

≤30 uS/cm

|

|

Magnetizable Material Content

|

≤15 PPM

|

|

Moisture Content

|

≤0.25%

|

|

pH

|

6-10

|

|

Whiteness/Transparency

|

≥80

|

|

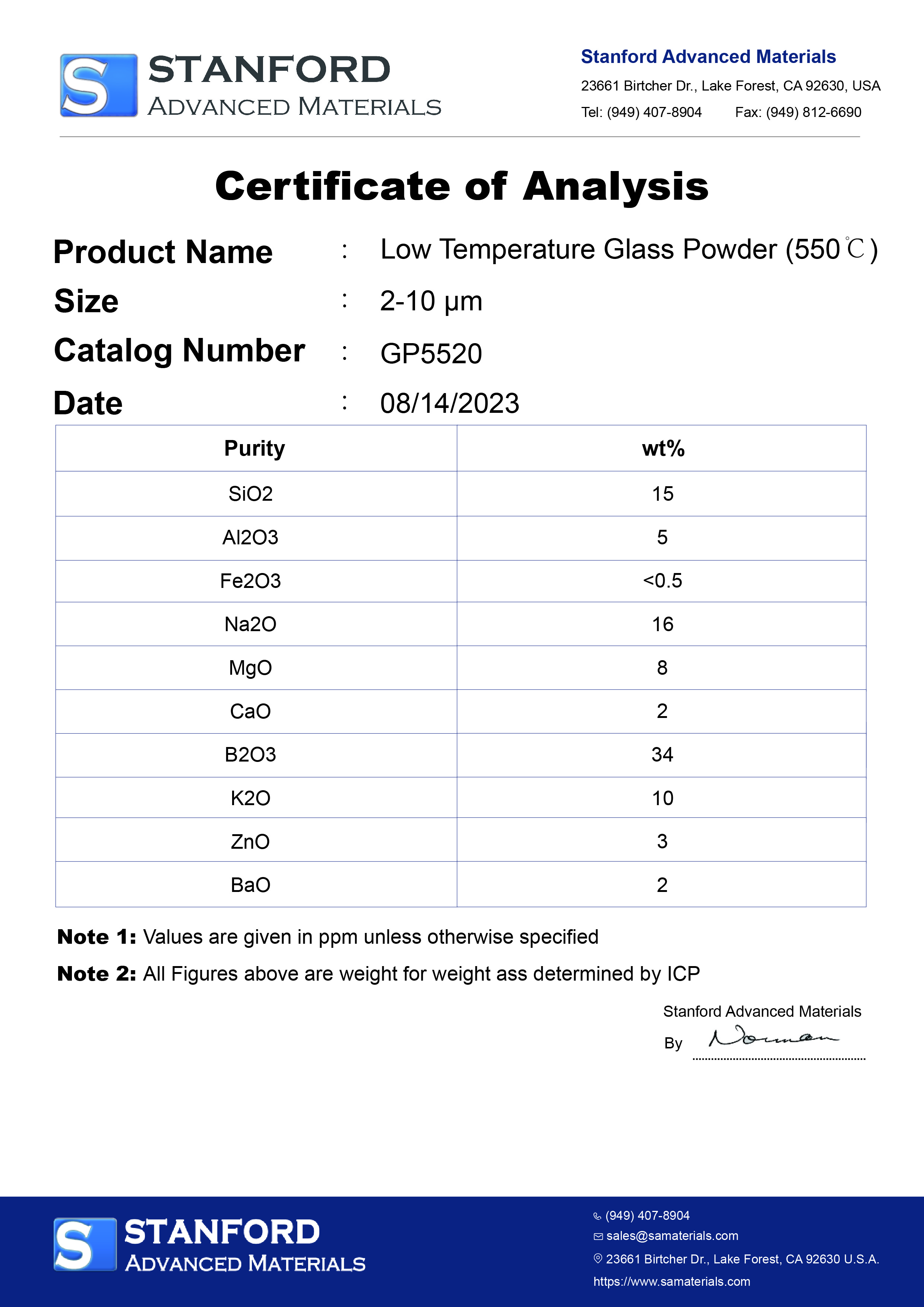

Chemical Data

|

|

SiO2

|

15%

|

|

Al2O3

|

5%

|

|

Fe2O3

|

<0.5%

|

|

Na2O

|

16%

|

|

MgO

|

8%

|

|

CaO

|

2%

|

|

B2O3

|

34%

|

|

K2O

|

10%

|

|

ZnO

|

3%

|

|

BaO

|

2%

|

Low Temperature Glass Powder (550C) Applications

1. Sealing materials: Low Temperature Glass Powders are often used as one of the main components of sealing materials. Due to its low melting point, it can be sintered and molded at relatively low temperatures to form seals with good sealing properties. These seals are commonly used in vacuum packages, sensors, electronic devices, and other fields.

2. Encapsulation materials: Low Temperature Glass Powder is also widely used in the preparation of encapsulation materials. It can be used as a substrate or encapsulation layer of encapsulation materials to protect electronic devices, integrated circuits, sensors, and other devices while providing good insulation and mechanical support.

3. Optical applications: Because of its high transparency and optical properties, Low Temperature Glass Powder is also used in some optical applications, such as optical glass preparation, optical lenses, optical windows, and other fields.

4. Ceramic materials: Low Temperature Glass Powder can be mixed with other ceramic powders for the preparation of ceramic materials, such as ceramic seals, ceramic substrates, ceramic coatings, and so on. It provides the structural support and chemical stability required for ceramic products.

5. Magnetic materials: Low Temperature Glass Powder is sometimes used to prepare magnetic materials, such as magnetic encapsulation, magnetic media, etc. for encapsulation and fixation of magnetic components.

Low Temperature Glass Powder Packing

Our Low Temperature Glass Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Low Temperature Glass Powder FAQs

Q1: Is glass powder flammable?

Fire and Explosion Hazard Overview: This material is considered non-flammable and non-combustible.

Q2: What is the hardness of glass powder?

Glass is one of the more difficult materials to process as it has a high hardness (Mohs hardness of ~4 to 7) and sharp edges upon fracture. Durable, field-proven, equipment and techniques are required for successful glass grinding, especially for ultra-fine milling requirements.

Q3: Where is glass powder used?

Glass powder is the result of glass being crushed using a mill. Glass powder is commonly used to make electronic tapes along, and can also be used as an additive or filler for other electronic applications. Blinding is a huge problem that occurs when sieving glass powder due to the high density of the product.