Ceramic Powder Description

Ceramic powder is sintered from one or more kinds of non-metallic minerals, clay, quartz and feldspar, kaolin, corundum, and other natural minerals as raw materials, formulated according to different formulas, processed and molded and sintered into porcelain, and then through the raw material compounding, ultra-fine grinding, precision grading and surface treatment and other processes made of powder materials. Ceramic Powder has the characteristics of high-temperature resistance, heat change resistance, friction resistance, acid and alkali corrosion resistance, chemical stability, and insulation. The specific chemical composition and performance characteristics of the products depend on the raw materials, formulations, and firing processes used. Stanford Advanced Materials (SAM) can provide products with various particle sizes and surface treatments according to your requirements, and provide solutions for industrial applications.

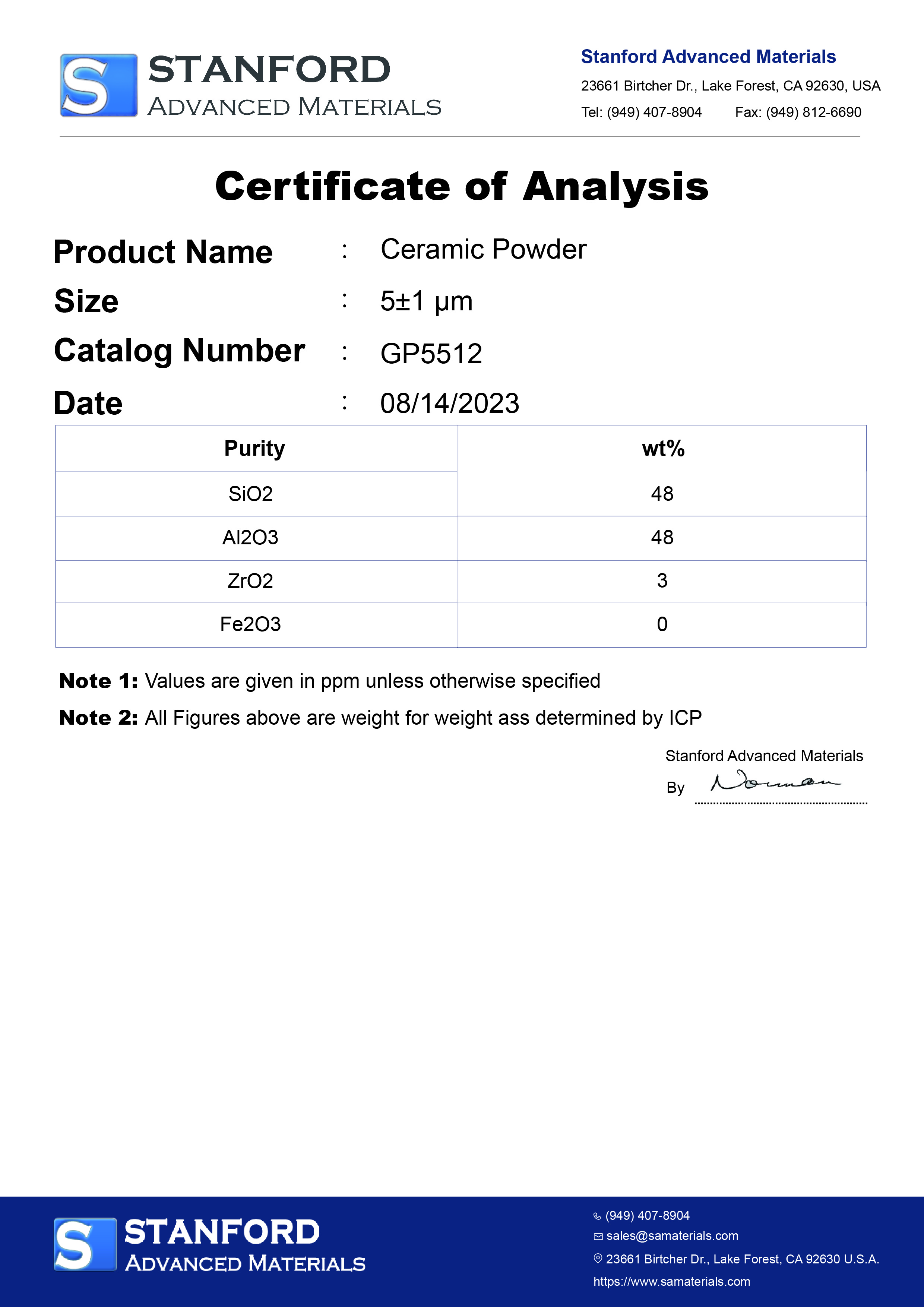

Ceramic Powder Specifications

|

Physicochemical Information

|

|

Average Particle Size D50

|

5±1μm

|

|

Max. Particle Size D100

|

13±3μm

|

|

Density

|

3.2 g/cm3

|

|

Mohs Hardness

|

7.5

|

|

Specific Surface Area

|

2.5±0.2 m2/g

|

|

Refractive Index

|

1.58

|

|

Dielectric Constant DK

|

4.65εr

|

|

Dielectric Loss Df

|

0.0018 tgδ

|

|

Linear Expansion Coefficient

|

14*10-6 1/K

|

|

Conductivity

|

≤30 uS/cm

|

|

Chemical Data

|

|

SiO2

|

48%

|

|

Al2O3

|

48%

|

|

ZrO2

|

3%

|

|

Fe2O3

|

0.01%

|

Ceramic Powder Applications

1. Advanced ceramic materials: High-performance Ceramic Powders are usually used to manufacture advanced ceramic materials, such as alumina, zirconia, silicon carbide, silicon nitride, and so on. These materials are characterized by excellent high-temperature resistance, corrosion resistance, and insulating properties, and are widely used in aerospace, automotive, electronics, medical devices, and other fields.

2. Coatings and pigments: Ceramic Powders are often used as raw materials for coatings and pigments to coat metal surfaces, glass, ceramics, and other materials to enhance their abrasion resistance, corrosion resistance, insulation, and other properties, as well as for decoration and beautification.

3. Fillers: Ceramic Powder can be added as fillers to plastics, rubber, concrete, and other materials, used to enhance the hardness, strength, wear resistance, and other properties of the material.

Ceramic Powder Packing

Our Ceramic Powder is carefully handled during storage and transportation to preserve the quality of our product in its original condition.