Fused Silica Description

Fused Silica is the amorphous (glassy) form of silica (quartz, silica) which is prepared firstly by the formation of glassy lumps of high purity quartz after melting at a high temperature of over 1760℃, followed by rapid cooling, and then crushed manually and sorted into different grades, and then crushed and ground into sand by machine processing. With excellent high-temperature resistance properties, Fused Silica provided by Stanford Advanced Materials (SAM) can be used in refractory furnace charge, quartz crucible caskets, as well as water filtration, artificial stone plates and sandblasting and rust removal, and many other applications.

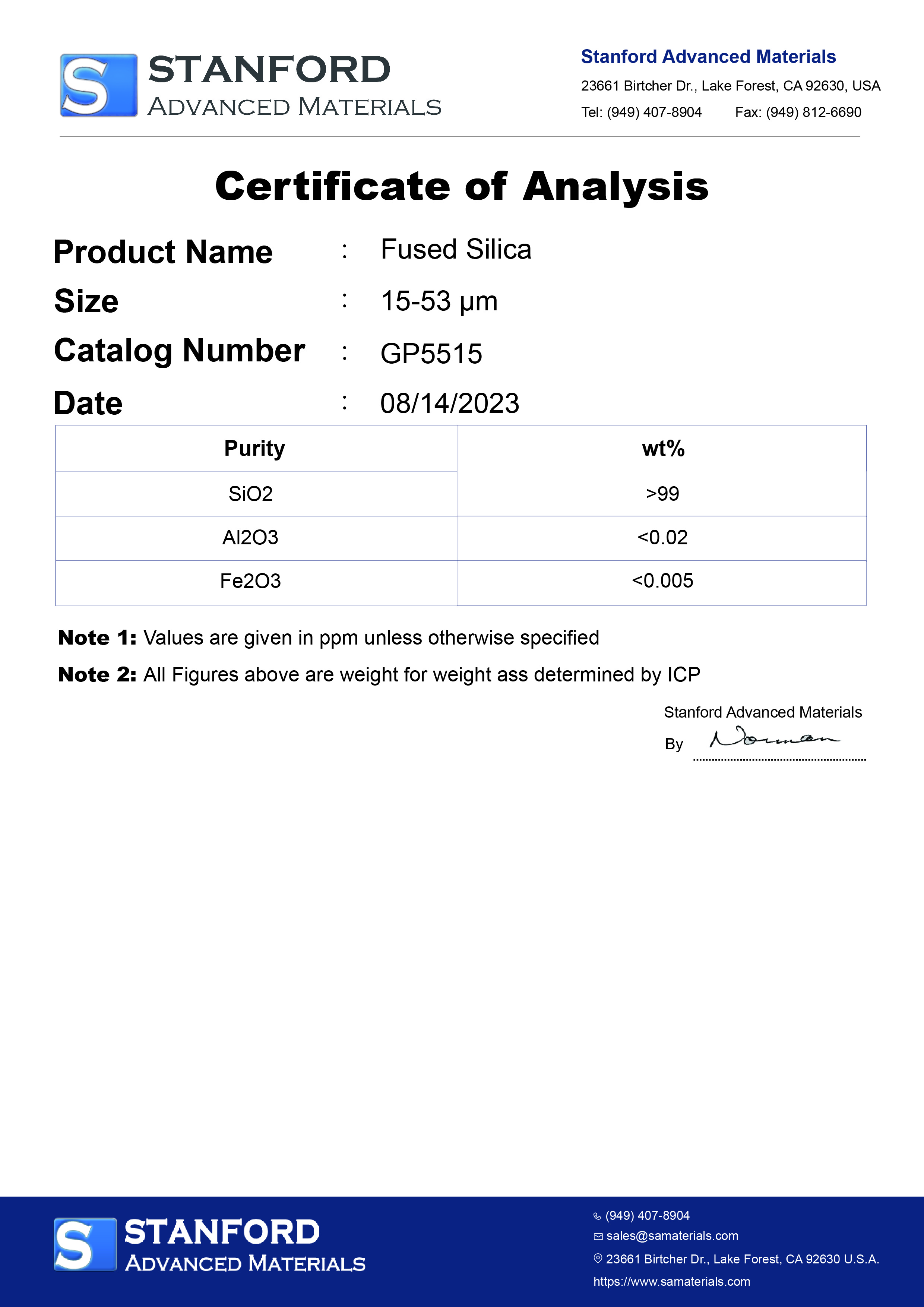

Fused Silica Specifications

|

Physicochemical Information

|

|

Density

|

2.2 g/cm3

|

|

Mohs Hardness

|

6

|

|

Thermal Conductivity

|

1.1W/K·m

|

|

Dielectric Constant DK

|

3.88εr

|

|

Dielectric Loss Df

|

0.0002 tgδ

|

|

Linear Expansion Coefficient

|

0.5*10^-6 1/K

|

|

Conductivity

|

≤30 uS/cm

|

|

Chemical Data

|

|

SiO2

|

>99%

|

|

Al2O3

|

<0.02%

|

|

Fe2O3

|

<0.005%

|

Fused Silica Applications

1. Refractories: Due to its high-temperature resistance and chemical stability, Fused Silica can be used to manufacture refractories, such as refractory bricks, refractory coatings, refractory fibers, etc., which are used in the manufacture of refractory components for high-temperature industrial furnaces, glass kilns, and other refractory components.

2. Water Filtration: Fused Silica is commonly used as part of the filtration media for water treatment, such as in reverse osmosis water treatment systems. The microscopic particles of quartz sand can effectively filter out impurities, microorganisms, and particulate matter from water, improving the purity and cleanliness of water.

3. Artificial stone panels: Fused Silica can be used as one of the main components of artificial stone panels. By mixing raw materials such as quartz sand, resin, and pigment, after processing and pressing highly uniform and durable artificial stone panels can be made, which are used for indoor decoration, countertops, floors, walls, and so on.

4. Sandblasting for rust removal: Fused Silica is widely used in sandblasting for rust removal and surface treatment. In the sandblasting process, quartz sand particles sprayed at high speed remove rust spots, dirt, and coatings from metal surfaces, leaving the surface smooth and even, ready for subsequent painting or surface treatment.

Fused Silica Packing

Our Fused Silica is carefully handled during storage and transportation to preserve the quality of our product in its original condition.