Case Study: Empowering Space Innovation Aluminum Alloy Powder

Introduction

As humanity ventures farther into the cosmos, the demand for materials that can withstand the rigors of space travel becomes increasingly paramount. Aluminum Alloy Powder has emerged as a key player in this endeavor, offering a remarkable combination of strength, lightweight construction, and thermal management capabilities. This exploration will uncover the crucial applications of this powder in space technology. Hope that you can have a better understanding of its benefits and applications.

[1]

[1]

Figure 1. Space Science

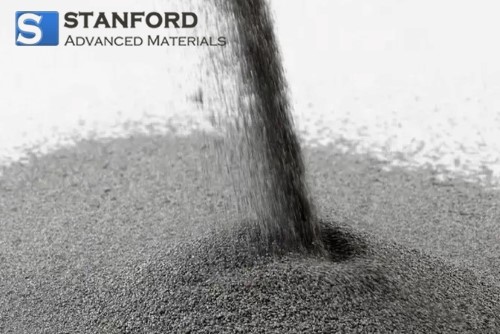

Unlocking the Potential of Aluminum Alloy Powder

Aluminum Alloy Powder finds extensive application because of its strength, corrosion resistance, thermal conductivity, etc. Its specific attributes in space include:

Lightweight Construction: The low density of Aluminum Alloy Powder is essential in space applications since minimizing weight is key to achieving efficient launches and maneuvers.

Strength and Durability: Despite their lightweight nature, these alloys offer remarkable strength to withstand the extreme conditions of space travel.

Thermal Management: Aluminum Alloys possess excellent thermal conductivity, allowing them to effectively manage heat dissipation in spacecraft components.

Corrosion Resistance: The inherent corrosion resistance is vital for prolonged exposure to the harsh environment of space, where there is no protective atmosphere.

Figure 2. Aluminum Alloy Powder

Space Applications of Aluminum Alloy Powder

Therefore, Aluminum Alloys are used to construct various structural components of spacecraft, including frames, panels, and support structures. They are often employed in the construction of payload fairings and launch vehicle structures. Besides, they are used in the creation of heat shields and radiators that manage the extreme thermal conditions faced during re-entry into the Earth's atmosphere and the dissipation of excess heat generated by equipment on board. You can also find them in additive manufacturing (3D printing) techniques to create intricate and customized components for space missions.

Case Study: Aluminum Alloy Powder Used for Space

--The Challenge

Some customers were seeking to procure Aluminum 7075 Powder tailored for space applications. SAM took specific specifications and diverse use cases into consideration and recommended selecting a particle size of less than 45 microns to ensure fluidity and consistency during processing.

--The Solution

The following potential applications are also recommended.

Spacecraft Components: Aluminum 7075 Powder can be used for crafting essential structural elements, casings, and connectors for space-bound crafts. The reason is that the material's exceptional strength-to-weight ratio contributes to weight reduction, augmenting spacecraft efficiency and payload capacity.

Engine Parts: The 7075 powder is employed to fabricate engine components for spacecraft as well, including propulsion chamber casings and combustion chamber walls.

Conductive Components: Given the significance of heat and electrical conduction in space settings, Aluminum 7075 Powder serves as a resource for creating conductive parts such as heat sinks and electronic packaging. These components ensure efficient heat dissipation and reliable transmission of electrical signals.

--The Results

By embracing the specified particle size and capitalizing on the manifold applications, Aluminum 7075 Powder proves indispensable in revolutionizing space engineering endeavors. Its capacity to produce lightweight yet durable components significantly advances the domain of spacecraft development, propulsion systems, and conductive apparatuses indispensable for space exploration.

Conclusion

In short, with lightweight construction, impressive strength, thermal management prowess, and corrosion resistance, Aluminum Alloy Powder stands as a vital material in the challenging environment of space. Stanford Advanced Materials (SAM) has extensive experience in manufacturing and supplying high-quality 7075 Aluminum Alloy Powders. Send us an inquiry if you are interested.

Reference:

[1] College of Engineering. Space Sciences and Engineering. College of Engineering Miami.Retrieved August 15, 2023, from https://www.coe.miami.edu/research/strategic-thrusts/space-sciences-and-engineering/index.html