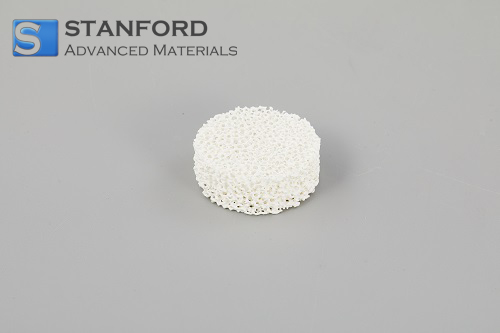

Cordierite-Mullite Ceramic Honeycomb Descriptions

Cordierite-Mullite Ceramic Honeycomb combines the superior properties of cordierite and mullite ceramics to offer an exceptional material solution. Cordierite ceramic, a magnesium aluminum silicate, is renowned for its excellent thermal shock resistance, low thermal conductivity, and minimal thermal expansion. These attributes make it a cost-effective choice for applications requiring rapid temperature fluctuations, such as kiln furniture.

Mullite, on the other hand, is celebrated for its high-temperature stability, remarkable strength, and resistance to creep. Additionally, mullite possesses a low dielectric constant and outstanding electrical insulation properties, making it an ideal structural material for demanding environments.

Cordierite-Mullite Ceramic Honeycomb Specifications

|

Physical Data

|

|

Property

|

Unit

|

Value

|

|

Coefficient of thermal expansion

|

10-6/K-1

|

<4

|

|

Specific Heat Capacity

|

J/Kg·K

|

850-1000

|

|

Operating Temperature

|

℃

|

<1350

|

Cordierite-Mullite Ceramic Honeycomb Typical Chemical Composition

|

Content

|

Value wt%

|

|

SiO2

|

35-45

|

|

Al2O3

|

40-50

|

|

MgO

|

3-13

|

|

K2O+Na2O

|

<1.0

|

|

Fe2O3

|

<1.5

|

Cordierite-Mullite Ceramic Honeycomb Applications

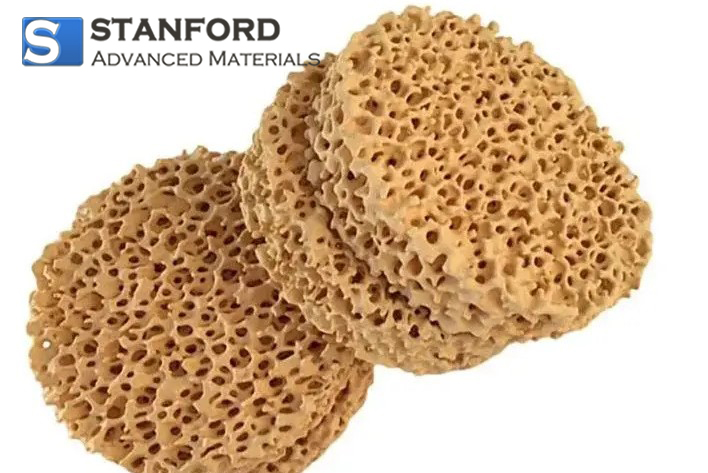

-

Catalyst Support

- Automobile Exhaust Purification: Utilized as catalyst carriers covered with γ-Al₂O₃ for effective emission control.

- Boiler Exhaust Denitrification (NOx): Facilitates the reduction of nitrogen oxides in industrial exhaust streams.

- Industrial Exhaust Deodorization: Removes toxic and harmful gases, ensuring cleaner emissions.

-

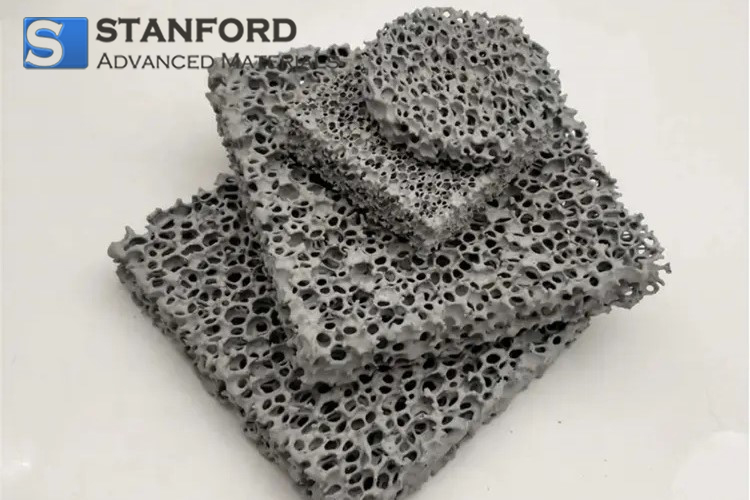

Refractory Kiln Furniture

- Lightweight Structure: Extruded honeycomb ceramic kiln furniture is 60%-75% lighter than traditional kiln ware, enhancing ease of handling.

- Rapid Heat Transfer: Promotes quick firing processes, improving the efficiency and performance of ceramic products like ferrites and electronic ceramics.

-

Wall Flow Filters

- Diesel Gas Exhaust Purification: Porous thin walls effectively filter and eliminate carbon particles, ensuring cleaner diesel emissions.

Cordierite-Mullite Ceramic Honeycomb Packaging

SAM ensures that Cordierite-Mullite Ceramic Honeycomb is meticulously packaged to prevent any damage during storage and transportation. Our packaging solutions are designed to maintain the integrity and quality of the product, ensuring it arrives in pristine condition ready for immediate use.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using Cordierite-Mullite Ceramic Honeycomb over single-material honeycombs?

Cordierite-Mullite Ceramic Honeycomb leverages the combined benefits of both cordierite and mullite ceramics. This composite structure offers enhanced thermal shock resistance, higher temperature stability, and superior mechanical strength compared to single-material honeycombs. Additionally, the combination provides better electrical insulation and lower dielectric properties, making it suitable for more demanding applications.

2. Can Cordierite-Mullite Ceramic Honeycomb be customized to specific dimensions and shapes?

Yes, SAM specializes in customizing Cordierite-Mullite Ceramic Honeycomb to meet your exact specifications. Whether you require unique dimensions, specific cell densities, or specialized shapes, our team can tailor the honeycomb structures to fit your project requirements, ensuring optimal performance and integration into your systems.

3. How should Cordierite-Mullite Ceramic Honeycomb be handled and installed to prevent damage?

To maintain the integrity of Cordierite-Mullite Ceramic Honeycomb during handling and installation, it is essential to follow best practices. Always handle the honeycomb gently to avoid mechanical stress or impacts. Use appropriate lifting equipment for larger pieces, and ensure that the installation environment is free from excessive vibrations or shocks. Additionally, proper packaging and storage conditions should be adhered to until installation.

4. What is the typical lifespan of Cordierite-Mullite Ceramic Honeycomb in industrial applications?

The lifespan of Cordierite-Mullite Ceramic Honeycomb varies depending on the specific application and operating conditions. However, due to its high thermal stability, excellent mechanical strength, and resistance to chemical corrosion, it generally offers a long service life, often exceeding several years in demanding industrial environments. Regular maintenance and adherence to operational guidelines can further extend its durability.

5. Are there any specific environmental considerations when using Cordierite-Mullite Ceramic Honeycomb?

Cordierite-Mullite Ceramic Honeycomb is considered environmentally friendly due to its non-toxic composition and high durability, which reduces the need for frequent replacements. Additionally, it contributes to environmental sustainability by improving the efficiency of processes such as exhaust purification and emission control. However, it is important to handle and dispose of any waste materials by local environmental regulations to minimize any potential impact.

English

English Española

Española Deutsch

Deutsch Français

Français Italiano

Italiano