The Corrosion Protection Technology of Aluminum Alloys

Advantages of Aluminum Alloys in Shipbuilding

The aluminum alloy has the advantages of low specific gravity, high specific strength, good seawater corrosion-resistance, non-magnetic property and good low-temperature performance, which has been paid more and more attention in the shipbuilding industry.

Ships using aluminum alloy as hull material can effectively reduce weight, improve stability and speed, and enhance the ship's technical and tactical performance. Aluminum alloy is especially suitable for the high-speed hydrofoil, hovercraft, small surface craft and some special purpose ships. With the development of inert gas welding technology for aluminum alloy, the production cost has been reduced, and the advantages of aluminum alloy materials and their application in the marine environment have been continuously expanded.

Coating Systems for Marine Environments

The marine environment is relatively harsh, so the requirements of anti-corrosion of aluminum alloy in the working environment are higher. The corrosive environment of aluminum alloy ship bottom and above the water line is different. The ship bottom is mainly the infiltration erosion of natural seawater and the attachment of aquatic organisms, and the above water line is mainly salt spray corrosion and atmospheric aging. Therefore, the anti-corrosion paint requirements of the ship bottom and above the water line are not identical.

- Below the Waterline: Coatings must resist infiltration erosion and biofouling. Polyurethane topcoats, epoxy primers, and specialized anti-fouling paints are commonly used.

- Above the Waterline: Coatings need good weather resistance, gloss retention, and compatibility with primers. Polyurethane finishing coats, alkyd finishing coats, and acrylic finishing coats are typically used. Advanced fluorocarbon coatings, modified with epoxy or acrylic, provide enhanced performance.

Related reading: How Does Aluminum Alloy Protect Ships From Corrosion?

Corrosion Protection Technologies for Aluminum Alloys

To mitigate corrosion, other protective technologies and methods are employed:

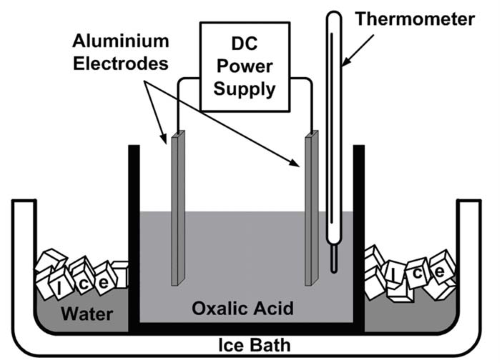

- Anodizing enhances the natural oxide layer on aluminum, providing increased corrosion and wear resistance. There are different types of anodizing, including sulfuric acid anodizing, hard anodizing, and chromic acid anodizing, each offering varying levels of protection and specific applications.

- Chromate Conversion Coating forms a protective chromate layer on the aluminum surface, offering good corrosion resistance and serving as a base for additional coatings.

- Organic Coatings such as paints, lacquers, and powder coatings create a physical barrier against corrosive elements. Common types include polyurethane coatings, which offer good UV resistance, epoxy coatings, which provide strong adhesion and chemical resistance, and powder coatings, which deliver a durable finish.

- Cathodic Protection involves using sacrificial anodes, such as zinc or magnesium, to protect aluminum by corroding in place of the alloy. Impressed current systems use an external power source to provide protection.

- Electroplating involves depositing a layer of metal, such as nickel or chromium, onto the aluminum surface to enhance corrosion resistance.

- Inhibitors are chemicals added to the environment to slow down the corrosion process. These can be either organic or inorganic inhibitors.

- Surface Treatments like laser surface melting, ion implantation, and shot peening modify the surface of aluminum to improve its corrosion resistance.

These technologies and methods collectively help in protecting aluminum alloys from corrosion, ensuring their durability and longevity in various applications, especially in harsh marine environments.

Conclusion

Aluminum alloys offer significant benefits for shipbuilding, including reduced weight, improved performance, and good corrosion resistance. Effective corrosion protection strategies, tailored to the specific environmental challenges faced by different parts of a vessel, ensure the longevity and reliability of aluminum alloy ships. Employing a combination of anodizing, coatings, cathodic protection, and other technologies maximizes the corrosion resistance of aluminum alloys in marine applications. For more information, please check Stanford Advanced Materials (SAM).

Reference:

[1] Ahmad, Hafiz Imran & Sharif, Muhammad & Hussain, Safdar & Badar, M. & Afzal, H.. (2013). Spectroscopic Study of a Radio-Frequency Atmospheric Pressure Dielectric Barrier Discharge with Anodic Alumina as the Dielectric. Plasma Science and Technology. 15. 900. 10.1088/1009-0630/15/9/13.