Tensile Strength: Basics and Examples

What Is Tensile Strength

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before it breaks or permanently deforms. It is a fundamental property of materials, particularly metals, plastics, and composites, and plays a crucial role in structural design, material selection, and product performance. Tensile strength is typically measured in units of pressure, such as pascals (Pa) or megapascals (MPa), and it reflects how well a material resists breaking under tension.

Tensile Strength and Young's Modulus

Tensile strength is often confused with Young's modulus (also known as the modulus of elasticity), but they represent different material properties.

- Young’s Modulus measures a material’s ability to resist elastic deformation under tension. It quantifies how much a material will stretch or compress under a given force, up until the yield point (before permanent deformation occurs).

- Tensile Strength is the ultimate point of stress before the material fails and breaks apart.

In simple terms:

- Young's Modulus tells you how stiff a material is.

- Tensile Strength tells you how much force the material can handle before breaking.

Both properties are critical in determining a material’s performance, particularly for components that will be subjected to stress or strain.

Factors Affecting Tensile Strength

Several factors can influence the tensile strength of a material:

1. Material Composition: The type and arrangement of atoms in the material affect its ability to resist stretching. Metals like steel have high tensile strength due to their crystalline structure, while some polymers are weaker.

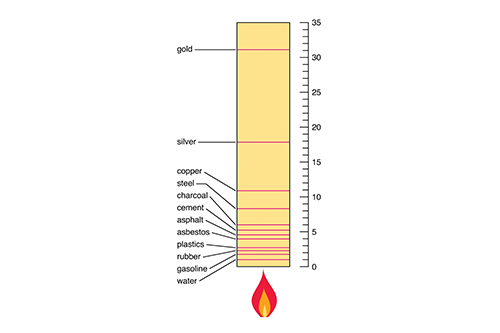

2. Temperature: Elevated temperatures can reduce a material's tensile strength by causing atoms to move more freely, resulting in a lower resistance to stretching. Conversely, very low temperatures may make certain materials brittle and more prone to fracture.

3. Grain Structure: The alignment and size of grains in a material can impact its tensile strength. Fine-grained materials tend to have better tensile strength because smaller grains provide more points of resistance to dislocations.

4. Processing Methods: Techniques like cold working or heat treatment can improve tensile strength by modifying the material’s internal structure, leading to improved resistance to deformation.

5. Impurities and Defects: Any flaws, cracks, or impurities within a material will act as stress concentrators and reduce its tensile strength.

6. Strain Rate: The speed at which a material is pulled also affects its tensile strength. Faster strain rates typically result in higher measured tensile strength due to less time for the material to deform plastically.

Tensile Strength of Various Materials

The tensile strength varies significantly across different materials. Here are some common materials and their typical tensile strengths:

|

Material |

Tensile Strength (MPa) |

Example Uses |

|

Steel |

250 - 2,000 |

Structural beams, reinforcement bars, automotive parts |

|

Aluminum |

90 - 570 |

Aircraft components, packaging, and lightweight structures |

|

500 - 1,400 |

Aerospace, medical implants, and high-performance engineering |

|

|

Copper |

210 - 400 |

Electrical wiring, plumbing, and industrial applications |

|

Concrete |

2 - 5 |

Foundations, bridges, and buildings |

|

Plastic (Polyethylene) |

20 - 40 |

Packaging, containers, and lightweight applications |

|

3,500 - 6,000 |

Aerospace, sports equipment, and automotive parts |

|

|

Wood |

30 - 150 |

Construction, furniture, and carpentry |

For more materials, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

What is the difference between tensile strength and yield strength?

Tensile strength is the maximum stress a material can withstand before breaking, while yield strength is the point at which the material begins to deform plastically. Yield strength marks the end of the material’s elastic behavior and the start of permanent deformation.

What material has the highest tensile strength?

Carbon fiber has one of the highest tensile strengths, ranging from 3,500 MPa to 6,000 MPa, making it ideal for high-performance applications such as aerospace and sports equipment.

Can tensile strength be improved?

Yes, tensile strength can often be improved through heat treatments, cold working, or alloying processes. For instance, steel can be strengthened through quenching and tempering processes.

How does temperature affect tensile strength?

At high temperatures, materials generally experience reduced tensile strength because the atomic bonds weaken, making them more prone to deformation. Conversely, at extremely low temperatures, materials like metals can become brittle, reducing their tensile strength.

How is tensile strength measured?

Tensile strength is measured using a tensile test. A sample is stretched under controlled conditions, and the amount of stress the material can withstand before breaking is recorded. The test results give the ultimate tensile strength, yield strength, and other related properties.