Experiment on Magic Shape Memory Nitinol Wire by SAM

Nitinol is an alias of the nickel-titanium alloy. It was named after its composition and place of discovery, Nickel Titanium and Naval Ordnance Laboratory, respectively. As the term indicates, nitinol is composed of two metals, nickel (denoted as Ni) and titanium (denoted as Ti), with each component being roughly 50% and adding each other up to 100%.

Although the material properties of nitinol alloys depend upon their precise composition, they all share two interesting features. One is superelasticity or pseudoelasticity. The other is shape memory which looks kind of magic as we later demonstrate to you. Nitinol is rather elastic to the deformation imposed by external forces only at a narrow scope of temperature which should be above a critical temperature named "transformation temperature". This is the so-called superelasticity. Shape memory means nitinol is able to recover its originally normal shape from a deformed one at a low temperature when heated at a relatively high temperature that must be above the transformation temperature as well. The shape-memory effect is also found in gold-cadmium alloys and copper-zinc alloys. These two special properties of nitinol can be explained by "martensitic transformation", a reversible phase transformation between two or more solid states of a material.

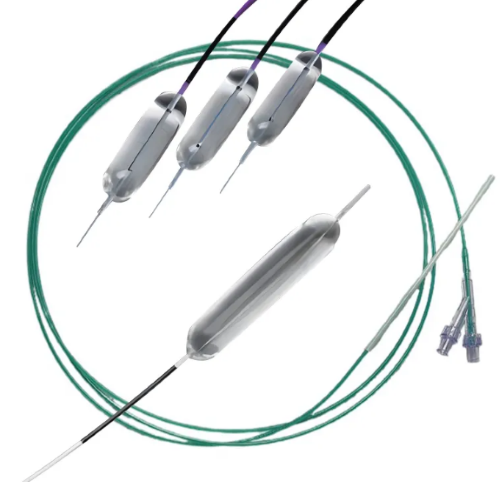

Right now Stanford Advanced Materials (SAM) produces a short video, using nitinol wires, to show the superelasticity and shape memory of nitinol. For a better understanding of the video, subtitles are attached at the end. Use a VPN service if the video fails to load. SAM also provides you with more details about nitinol.

Nitinol video subtitles

- Hi, this is Alex with Stanford Advanced Materials, and I'm here to introduce to you new material.

- It's called nitinol, which is an alloy of nickel and titanium.

- Nitinol has two very interesting properties, one is superelasticity.

- To demonstrate, I'm going to bend it into the type of coil.

- You can see no matter how I bend it, it bounces right back to shape.

- The other property is called shape memory.

- So I'm gonna take this nitinol wire.

- And I'm gonna put it into a bowl of ice water, like so.

- And here I'm gonna bend it.

- And unlike before it's actually gonna hold the bend.

- It's be curled, like so.

- Next, I'm gonna put it into a bowl of warm water.

- And it's gonna bounce right back.

- So I'll do it again.

- I'm gonna bend it in the cool water like so.

- The wire is gonna preserve that bend.

- As soon as I put it into warm water.

- It bounces right back.

- So nitinol wire has several applications.

- It's used in fishing wire.

- It’s used in the frame of glasses.

- And it's also used in dental braces.