LCP Film: Enabling 5G, Wearables, and Aerospace Advances

1 Introduction

Liquid crystal polymers (LCPs) are high-performance polymers that exhibit both fluidity and molecular order in liquid crystal phases when heated or dissolved. Characterized by their rigid, rod-like molecular chain structures, LCPs demonstrate outstanding high-temperature resistance, dielectric stability, and dimensional robustness. Since the 1970s, advancements in LCP materials have led to their use across electronics, telecommunications, and industrial manufacturing.

LCPs can be classified into several types based on thermal and processability properties, each optimized for specific applications: Type I for high-heat-resistant electronic components, Type II for antenna materials, and Type III for connecting tubes and sensors. Among LCP grades, LCP films possess distinct electrical and mechanical properties, including low dielectric constants (2.9 to 3.5), minimal water absorption, excellent thermal stability (heat deflection temperatures between 250-320°C), and impressive tensile strength. These characteristics make LCP films highly suitable for applications in high-speed, high-frequency electronics, such as 5G mobile antennas, wearable circuits, and aerospace communication systems, where material performance is critical to the efficiency and reliability of advanced technologies.

2 Introduction of LCP Film

Building on their high-performance nature, liquid crystal polymers (LCPs) offer fluid and molecularly ordered structures in liquid crystal phases when heated or dissolved. LCPs have a rigid, rod-like molecular chain structure and exhibit excellent high-temperature resistance, dielectric properties, and dimensional stability.

Since its development in the 1970s, LCP has evolved into various forms tailored for electronics, telecommunications, and industrial manufacturing. LCP can be categorized into solvatochromic liquid crystals, thermochromic liquid crystals, and piezotropic liquid crystals, of which thermochromic liquid crystals are the most widely used.

According to the product requirements, LCPs are available in injection molding, film, and fiber grades. LCP can be divided into types I, II, and III according to the different synthetic monomers. Type I LCP has high heat resistance, type II has high heat resistance and processability, and type III has weak heat resistance. After the commercialization of Type I LCP in 1972, Type II and Type III were developed in 1984 and 1976, respectively. Type I is suitable for electronic components, and type II is most suitable for antenna materials. Type I is suitable for electronic components, Type II is best suited as antenna material, and Type III is used for connecting tubes and sensors.

LCP films are stable at high speeds and high frequencies. Their dielectric constants range from 2.9 to 3.5, which makes them suitable for high-speed, high-frequency applications. Low dielectric loss allows for excellent performance in the GHz band. LCP films absorb less than 0.04% water and have a low CTE (10-17 ppm/°C), ensuring stability in environments with extreme humidity and temperature variations. LCP films have a heat deflection temperature of 250-320°C, providing them with excellent thermal stability and high performance in high-speed, high-frequency applications. With a tensile strength of 150-300 MPa and Young's modulus of 10-25 GPa, LCP films maintain stability even in high-temperature environments, offering good thermal shock resistance.

Due to its excellent electrical properties, LCP film is widely applied in advanced electronic applications.

Fig. 1 LCP Films

3 Applications of LCP Film in Different Fields

3.1 Flexible Wearable Circuit

LCP films provide excellent dielectric properties, making them highly effective insulators. This is essential for wearable electronics, where reliable electrical performance prevents short circuits and signal interference. The inherent flexibility of LCP films enables the development of compact, conformable circuit designs that can easily integrate into garments and accessories, allowing for more creative and functional wearable technology designs. LCP materials also help maintain signal integrity with their low dielectric constant and low loss tangent, crucial for high-frequency applications like fitness trackers and smartwatches.

For user comfort, LCP films offer both high tensile strength and flexibility, which enhance the durability and wearability of devices. They can withstand bending and stretching without compromising their structural integrity, making them ideal for applications that require frequent motion. Besides, the lightweight nature of LCP films contributes to the overall comfort of wearable devices. Users are more likely to wear devices that are unobtrusive and do not add significant bulk.

LCP films can be processed at high flow rates, allowing for complex geometries and detailed designs. This versatility is beneficial for manufacturers looking to create innovative wearable technologies. LCP has a high thermal resistance, allowing it to maintain performance across a wide temperature range. This is particularly beneficial for wearables that may be exposed to varying environmental conditions and body heat, ensuring consistent functionality. LCP materials are resistant to a wide range of chemicals, including sweat and other bodily fluids. This makes them suitable for wearable applications, as they can withstand exposure to various substances without degrading.

Fig. 2 Flexible Wearable Circuit

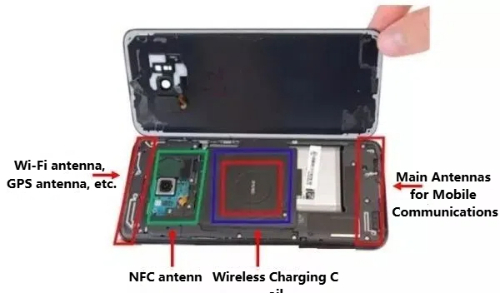

3.2 5G Mobile Phone Antenna

LCP films are increasingly used in 5G mobile phone antennas due to their unique properties that align with the demanding requirements of high-frequency communication. LCP has a low dielectric constant, which helps reduce signal loss at high frequencies, a critical factor for 5G applications that operate in millimeter-wave bands. The low loss tangent of LCP contributes to better signal integrity, ensuring that more of the transmitted signal reaches its destination without degradation. LCP antennas can be designed to support wide bandwidths, enabling multiple frequency bands to be accessed simultaneously. This is especially important for 5G technologies that utilize frequency division multiplexing. LCP films can be easily integrated with printed circuit boards (PCBs), allowing for efficient assembly and enhanced performance. This compatibility is crucial for the miniaturization of devices while maintaining high-performance levels. The thin profile of LCP films enables the development of compact antennas, essential for modern smartphones that prioritize slim designs. This compactness also aids in the overall aesthetics of the device.

LCP films maintain their properties over a wide temperature range. This thermal stability is essential for 5G antennas, which can generate heat during operation. Maintaining performance under various thermal conditions is crucial for device reliability. LCP films are flexible yet robust, allowing for the design of lightweight and compact antennas that can be integrated seamlessly into mobile devices without adding bulk. Their mechanical strength helps resist deformation during manufacturing and usage. LCP materials exhibit excellent resistance to moisture and chemicals, which is vital for devices that may be exposed to environmental factors over time. This durability ensures that the antenna maintains its performance and integrity throughout the device's lifecycle.

The processing capabilities of LCP allow for mass production of antennas with consistent quality, making them a cost-effective choice for manufacturers looking to produce 5G smartphones at scale.

Fig. 3 Cell Phone Internal Antenna

3.3 Large Aircraft Radio Frequency Antenna

LCP films are increasingly utilized in RF (radio frequency) antennas for large aircraft due to their exceptional properties that cater to the demanding requirements of aerospace applications. The first reason is that LCP materials exhibit a low dielectric constant, which minimizes signal loss and allows for efficient transmission of high-frequency signals crucial for communication systems in modern aircraft. Furthermore, low-loss tangent helps maintain signal integrity, ensuring that RF signals are transmitted effectively with minimal distortion, which is vital for reliable communication and navigation. LCP antennas can support a wide range of frequencies, which is beneficial for modern aircraft that require multiple communication channels for navigation, air traffic control, and passenger connectivity. This capability enhances overall communication efficiency.

LCP films can withstand extreme temperatures typically experienced in aviation environments, ensuring consistent performance across various operational conditions. This stability in the wide operating temperature range is essential for antennas that may be exposed to fluctuating temperatures during flight. The combination of flexibility and strength in LCP films allows for the design of lightweight, durable antennas that can be seamlessly integrated into the aircraft structure. This is particularly important in aerospace applications where weight reduction is key.

Impact Resistance: The robust nature of LCP can help withstand impacts and vibrations common in flight, ensuring the antenna maintains its performance and structural integrity over time. LCP materials are resistant to moisture and chemicals, which is critical for aircraft operating in diverse weather conditions. This durability ensures long-term reliability and reduces the risk of degradation in antenna performance.

The thin profile of LCP films allows for the development of compact antennas that do not add significant weight to the aircraft, contributing to fuel efficiency and overall performance. This aspect is particularly important in large aircraft where every gram matters. LCP films can be easily integrated into existing RF systems, making them a versatile choice for upgrading or replacing traditional antenna materials without extensive redesigns. This compatibility ensures smoother implementation in aerospace applications.

The processing capabilities of LCP enable high-volume production of antennas with consistent quality, making them a cost-effective option for aerospace manufacturers aiming to produce reliable RF solutions for large aircraft.

Fig. 4 Radio Frequency Antenna

3.4 5G Millimeter Wave Radar Communication

5G millimeter-wave radar communications is a revolutionary technology that utilizes the millimeter-wave frequency band (typically between 30 GHz and 300 GHz) for high-speed and high-capacity data transmission. Millimeter-wave bands offer greater bandwidth, and 5G can support higher data transmission rates compared to traditional mobile communication technologies such as 4G. 5G millimeter-wave technology can achieve data rates above 10Gbps, making it suitable for applications that require large amounts of data transmission, such as high-definition video streaming, virtual reality (VR), and augmented reality (AR). At the same time, high efficiency brings with it higher requirements for materials, which are aptly met by the excellent properties of LCP materials.

LCP films are gaining attention for use in 5G millimeter-wave radar communications, mainly due to their superior electrical properties, thermal stability, and mechanical strength.

LCP films have extremely low dielectric constants and dielectric losses, which are critical for signal transmission in the millimeter-wave band. Low dielectric loss reduces signal attenuation and improves transmission efficiency, enabling millimeter-wave radars to achieve higher signal quality and longer transmission distances. LCP films maintain stable electrical properties at high frequencies and are suitable for the frequency range (30 GHz to 300 GHz) required by millimeter-wave radars.

The thermal stability of LCP films allows them to operate in high-temperature environments without losing performance, which is important in 5G communication base stations and millimeter-wave equipment. LCP films can withstand long-term thermal cycling, ensuring that stable performance is maintained in harsh environments and extending the life of the equipment. In addition, LCP films have excellent mechanical strength and toughness, making them resistant to physical damage and environmental stress, making them suitable for use in mobile devices and base stations. The flexible nature of LCP films allows for the design of thinner antennas and circuits, which are suitable for miniaturized 5G millimeter-wave radar devices, contributing to increased device integration and lightweight.

In the design of millimeter-wave antennas, LCP film can be used as a dielectric material for the antenna. Its low dielectric constant helps improve antenna gain and radiation efficiency. The high-frequency performance and processability of LCP films also make them suitable for use in the fabrication of array antennas for the large-scale antenna arrays required for 5G communications. LCP films can also be used in the fabrication of radio-frequency circuit boards (RF PCBs), which provide efficient transmission paths for millimeter-wave signals. Its low-loss characteristics significantly improve RF signal transmission efficiency and reduce power consumption.

Encapsulation: In millimeter-wave RF devices, LCP films are also used as encapsulation materials to protect electronic components from the external environment.

Fig.5 Communication Radar Base Station 5g Device Signal Transmission

3.5 5G Base Station Flexible Transmitter Unit

LCP film has a low dielectric constant and low dielectric loss factor, which makes it suitable for high-frequency signal transmission in the millimeter band. This enables it to effectively reduce loss in high-speed, high-frequency signal transmission and ensure signal transmission quality. In the antenna arrays and signal transmission channels of 5G base stations, LCP film can be used as a flexible circuit material to optimize the transmission path of high-frequency signals, which helps to improve the transmission speed and stability of signals, especially in the interconnection and signal modulation circuits in the antenna units of the base stations.

LCP films have excellent flexibility and mechanical properties that allow them to maintain structural integrity in bending and stretching environments, etc. The thin and durable nature of LCP films allows them to be integrated with other circuit elements as part of a flexible antenna module. In the antenna module of a 5G small base station, such as a macro or micro station, LCP film can be used as a dielectric material to encapsulate the antenna and provide a flexible substrate for the antenna, which is especially useful in base station structures with limited space and complex shapes. At the same time, the LCP film can increase the bandwidth of the antenna module, which is conducive to the realization of multi-band signal reception and transmission.

In the application of millimeter-wave communication equipment in 5G base stations, the low-loss characteristics of LCP materials during transmission of millimeter-waves (frequencies of 24 GHz and above) enable them to effectively reduce attenuation and improve the efficiency of signal transmission on transmission lines in the microwave and millimeter-wave bands. In millimeter-wave communication equipment for 5G base stations, LCP films can be used for flexible connections between antennas and other circuit elements. This flexible transmission line can improve the signal integrity of millimeter-wave transmission, allowing the base station to maintain high-quality signal transmission even under different climatic conditions. In addition, LCP film has excellent stability in environments with large temperature fluctuations, making it suitable for outdoor 5G base stations.

LCP films are thinner and lighter than other substrate materials and can be processed in multiple layers while maintaining functional integrity. This processing characteristic allows LCP films to be used as a compact circuit substrate, and the lightweight nature of LCP films makes them particularly suitable for the miniaturization needs of 5G base station modules, especially in micro and nano base stations where device size is limited. Utilizing LCP film reduces the thickness and weight of the module, making it easier to install the base station equipment in special locations such as high-rise buildings and street light poles, expanding the 5G signal coverage.

Fig. 6 5G Base Station

4 Conclusion

In summary, LCP films provide a versatile and robust solution across various high-performance applications due to their exceptional dielectric properties, mechanical strength, thermal stability, and resistance to environmental stressors. These films play a vital role in enabling advancements in fields such as wearable electronics, 5G mobile antennas, aerospace RF systems, and millimeter-wave radar communications by supporting high-frequency signal integrity, device miniaturization, and flexible circuit designs. As demand for high-speed, high-capacity, and resilient technology continues to grow, LCP films offer the material properties needed to address the rigorous requirements of modern electronic, telecommunications, and industrial systems.

Stanford Advanced Materials (SAM) is a key provider of high-quality LCP films, supporting these critical applications with reliable material solutions.

Related Reading:

Main-chain Liquid Crystalline Polymers for Optical Applications