Liquid Crystal Polymer (LCP) Films in the Electronics Industry

1 Introduction

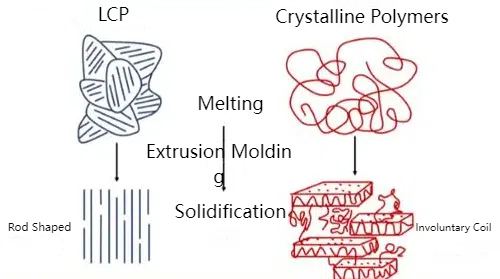

Liquid Crystal Polymer (LCP) is a unique class of high-performance polymer that exhibits liquid crystalline behavior when heated or dissolved in solvents. This property gives LCPs a distinctive combination of fluidity and molecular order, resulting in a material known for its exceptional thermal resistance, dielectric properties, and dimensional stability.

Characterized by a rigid rod-like molecular structure, LCPs exhibit tight molecular packing and high intermolecular forces, providing superior high-temperature performance, ultra-low water absorption, and outstanding flow characteristics. With their development in the 1970s, LCP materials have evolved into Type I, II, and III, each featuring unique structural compositions and thermal properties that suit various electronics, telecommunications, and industrial manufacturing applications.

Among the LCP products, LCP films are particularly valued for their stability under high-speed, high-frequency conditions, making them ideal for advanced electronic packaging and communication systems.

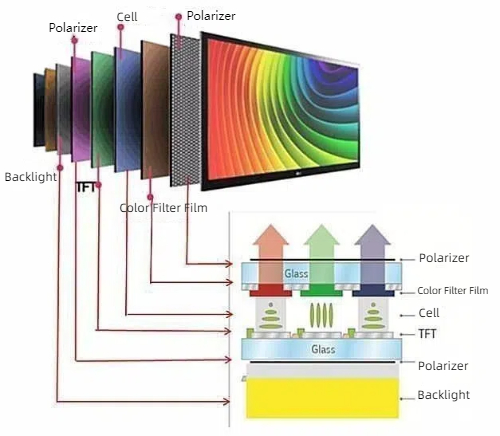

Fig. 1 Principle of Liquid Crystal Display

2 Introduction to LCP Film

2.1 What is LCP Film?

Liquid Crystal Polymer (LCP) is a macromolecule that can exist in a liquid crystal state after being melted by heat or dissolved by solvent. After being melted or dissolved by solvent, it will be transformed from a rigid fixed to a liquid substance with fluidity, while maintaining the orientation and order of the crystalline substance. Thus, liquid fluidity and crystalline molecules are formed in an orderly arrangement of the characteristics of the liquid crystal state, known as “super engineering plastics”. From the molecular structure, LCP has a rigid rod-shaped molecular chain structure, the molecular chain can be a highly oriented arrangement, the structure of the stacking of close, large intermolecular forces. Due to its special molecular structure, compared with other polymer materials, it has excellent high-temperature resistance, dielectric properties, good dimensional stability, ultra-high fluidity, and ultra-low water absorption.

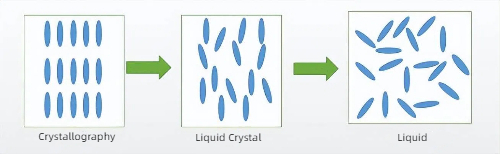

Fig. 2 Molecular Structure of Different States of Matter

2.2 Development History of LCP Film

The development of Liquid Crystal Polymers (LCPs) has occurred over several decades, with innovations emerging from different regions and companies. The history of LCP production can be traced back to the early 1970s when various types of LCP were introduced.

- Type I LCP: The first commercialized LCP, known as Ekonol, was developed in the United States in 1972. It was based on monomers such as p-hydroxybenzoic acid (PHB), bisphenol A (BP), and terephthalic acid (TPA), which gave it a highly rigid molecular structure and excellent heat resistance, making it suitable for electronic components like connectors. In 1979, Sumitomo Chemical in Japan further advanced this technology with the independent development of the E2000 series, positioning Japan as a key player in LCP production.

- Type II LCP: In 1984, Hoechst-Celanese introduced Type II LCP, branded as Vectra, marking a significant leap in LCP technology. Type II LCP, consisting of p-hydroxybenzoic acid (PHB) and 6-hydroxy-2-naphthoic acid (HNA), offered a simpler molecular composition and better mechanical properties, making it particularly suited for antenna materials. By 1996, this technology had spread globally, with Polyplastics producing LCP under the brand LAPEROS.

- Type III LCP: Eastman Kodak introduced Type III LCP in 1976, with production starting in 1986 under the brand name X-7G. This type featured a flexible ester-based structure, combining HBA (p-hydroxybenzoic acid) and PET (polyethylene terephthalate), but its reduced heat resistance limited its application primarily to plastic connecting tubes and sensors.

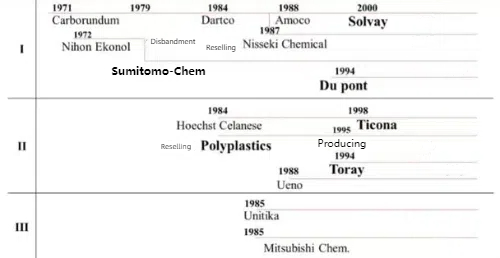

Fig. 3 Development History of LCP

2.3 Classification of LCP Films

LCP films can be classified based on their molecular properties, processing methods, and end-use applications. These classifications help in determining the appropriate LCP material for various industrial purposes.

2.3.1. Classification by Liquid Crystal Formation

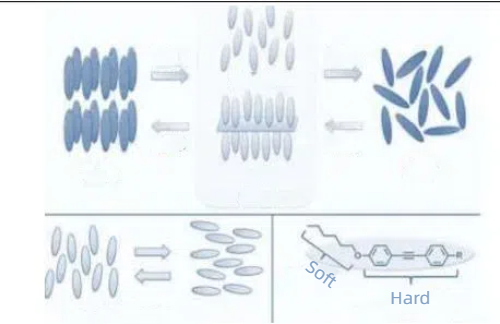

According to the different conditions for generating liquid crystals, LCP can be classified into Lyotropic LCP (LLCP), Thermotropic LCP (TLCP), and Piezotropic Liquid Crystals.

- Piezotropic Liquid Crystals are relatively rare;

- Lyotropic LCPs need to be processed in solution and are generally used as fibers and coatings;

- Thermotropic LCPs can be processed in the molten state to produce injection molding-grade, fiber-grade, and film-grade materials. They are currently the most widely used.

Fig. 4 Schematic Diagram of LLCP and TLCP

2.3.2. Classification by Product Grade

According to product requirements, LCP can be divided into injection molding, film, and fiber-grade materials.

- Injection grade LCP material is mainly used for injection molding to form complex geometries through fluidity at high temperatures. It has excellent heat resistance, chemical resistance, and mechanical strength, and is suitable for producing high-precision parts.

- Film grade LCP is mainly used to produce high-performance films with good heat resistance, electrical insulation, and chemical stability. The main advantage of LCP films is their low dielectric constant and low dielectric loss, making them particularly suitable for high-frequency applications in the electronics and electrical industries.

- Fiber-grade LCP can be processed into high-strength fibers with high tensile strength and modulus and is often used to reinforce composite materials. Fiber grade LCP has excellent heat resistance, chemical stability, and dimensional stability, making it suitable for high-performance fiber applications.

2.3.3. Classification by Heat Resistance and Molecular Structure

Based on the difference between the synthesized monomers and the heat production properties, the LCP materials can be classified into type I, type II, and type III.

- The molecular structure of type I LCP membrane consists of p-hydroxybenzoic acid, bisphenol A, and phthalic acid (PHB, BP, and TPA). Type I LCP heat distortion temperature in 250-350 ℃, heat resistance is relatively good; but in contrast, the processing performance of Type I LCP is weak, mainly used for electronic components such as connectors.

- Type II LCP film type II monomer consists of p-hydroxybenzoic acid and 6-hydroxy-2-naphthalene carboxylic acid (PHB and HNA), the heat distortion temperature range of 180-250 ℃; in the high heat resistance at the same time take into account the processing performance of the material, the most suitable for use as antenna materials.

- Type III monomer consists of HBA and PET, the heat distortion temperature is 100-200 ℃, Type III LCP heat distortion temperature, and heat-resistant performance is relatively weak, so it is less used at present.

Table 1 3 Types of LCP

Types | Heat Deformation Temperature | Molecular Structure |

Type I | 250-350℃ |  |

Type II | 180-250℃ |  |

Type III | 100-200℃ |  |

3 LCP Film Product Characteristics

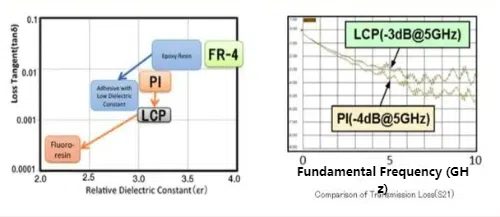

3.1 Stable Low Dielectric Constant and Dielectric Loss at High Speed and High Frequency

The dielectric constant is a parameter that measures a material's ability to store electrical energy under an electric field. LCP films have extremely low dielectric constants, typically between 2.9 and 3.5, which makes them ideal for high-speed and high-frequency applications. The lower the dielectric constant, the faster the electrical signal travels through the material, which increases the overall communication rate. At the same time, low Dk values help reduce signal delay and distortion, especially when transmitting high-frequency signals. The low dielectric constant allows LCPs to maintain excellent performance at frequencies above 10 GHz, making them suitable for use in millimeter-wave bands and 5G communications equipment.

Dielectric loss is the loss of energy converted to heat by a material under the action of an electric field and reflects the energy loss of a material in conducting a signal. The dielectric loss of LCPs is extremely low, typically in the range of 0.002 to 0.004. Its energy loss remains small even at high frequencies. A low Df value means that less energy is lost during signal transmission at high frequencies, which is critical for maintaining signal integrity and reducing noise interference. Especially in the GHz band, low dielectric loss effectively reduces signal attenuation in the transmission link and ensures data integrity over long distances or at high speeds. LCP materials generate less heat and are less susceptible to signal distortion or material deterioration due to temperature rise, ensuring stable operation over long periods in high-frequency and high-temperature environments.

The low dielectric constant and dielectric loss of LCP films allow them to excel not only at regular temperatures but also over a wide temperature range (-50°C to over 250°C). This makes it ideal for high-speed, high-frequency signal transmission in extreme environments.

The consistently low dielectric constant and low dielectric loss of LCP (Liquid Crystal Polymer) films in high-speed, high-frequency applications are key reasons for their widespread interest and use in modern electronics, communications, and high-frequency signal transmission.

Fig 5 LCP Significantly Reduces High-Frequency Transmission Losses

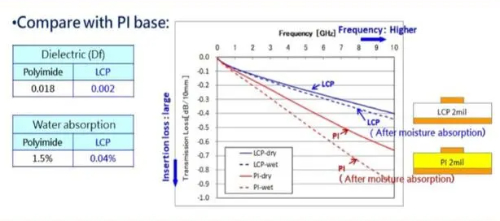

3.2 Low Water Absorption and Low Thermal Linear Expansion Coefficient

LCP (Liquid Crystal Polymer) films offer significant advantages in high-precision electronics and communications applications due to their low water absorption and low linear coefficient of expansion. These two characteristics play a key role in the stability of LCP film performance in harsh environments, especially where humidity and temperature can vary dramatically.

Water absorption is the ability of a material to absorb water from its environment. LCP film has an extremely low water absorption rate, typically less than 0.04%. This means that it absorbs virtually no moisture and its performance remains stable even in high humidity environments. Water absorption can significantly affect the electrical properties of the material, increasing the dielectric constant and dielectric loss. However, due to the extremely low water absorption of LCP films, humidity has very little effect on their electrical properties, ensuring quality signal transmission in humid environments. The low water absorption means that the physical dimensions of the material do not change significantly as a result of absorbing water, ensuring that it maintains high accuracy in environments where humidity fluctuates. These properties give LCP film surfaces good moisture resistance, making them suitable for use in environmentally sensitive electronic packages and external devices to provide additional protection.

The coefficient of Thermal Expansion (CTE) is the proportion of a material's length that expands with increasing temperature as the temperature changes. LCP film's coefficient of linear expansion is typically in the range of 10 ppm/°C to 17 ppm/°C, which is much lower than that of many other engineering plastics and high-frequency materials. The low CTE allows LCP films to remain virtually dimensionally unchanged during dramatic temperature changes, ensuring that they will not deform at high temperatures or under hot and cold cycling conditions. This is critical for precision electronics and high-frequency circuits, where LCP's low CTE is close to that of commonly used conductive materials such as copper, minimizing delamination, cracking, or connection failure due to expansion mismatches during thermal cycling. Especially in high-speed and high-frequency circuit boards, this feature can greatly enhance the reliability of the device. For applications requiring very high dimensional accuracy, such as flexible circuits, sensors, and microelectronic packages, the low CTE ensures the dimensional stability of LCP films during heat treatment, processing, and long-term use.

Fig. 6 Comparison of Transmission Loss Before and After Moisture Absorption Between LCP Substrate and PI Substrate

3.3 High-Dimensional Stability and Barrier Properties

LCP (Liquid Crystal Polymer) films are important in high-performance applications because of their outstanding high dimensional stability and barrier properties.

The high dimensional stability of LCP films is due to their unique molecular structure, especially their liquid crystalline arrangement of molecules, which allows the material to maintain its size and shape when subjected to heat or stress. The coefficient of thermal expansion (CTE) of LCP films is extremely low, making them virtually immune to thermal expansion or contraction at elevated temperatures and severe temperature changes. 17 ppm/°C, resulting in virtually no thermal expansion or contraction at elevated temperatures and dramatic temperature changes. Compared to other polymer materials, LCP films exhibit minimal dimensional change at elevated temperatures, which is important in heat-sensitive devices. LCP films have good heat resistance and can typically operate in environments above 250°C while maintaining their physical dimensions and morphology. This characteristic makes it possible to maintain high precision in high-temperature environments and avoid heat-induced material deformation.

In addition, the molecular arrangement and high-strength molecular bonds of LCP film give it excellent tensile strength and impact resistance, allowing it to maintain its original shape and dimensions even under mechanical stress. This is critical to the reliability of precision electronics. Due to this high dimensional stability, LCP films are widely used in high-frequency circuit boards, flexible circuits, precision electronic packages, and other areas where highly accurate and stable dimensions are required to ensure the reliability of the devices in long-term use and harsh environments.

LCP films have excellent barrier properties to gases, moisture, chemicals, etc., making them excellent performers in many harsh environments. LCP films have extremely high barrier properties to a wide range of gases (e.g., oxygen, carbon dioxide, nitrogen, etc.). This property is critical to extending the life of electronic components and precision equipment, especially where oxidation prevention is required. LCP films have very low water absorption, typically less than 0.04%, and effectively block water vapor penetration. This gives them excellent stability in humid environments and prevents moisture from affecting the electrical properties of the material. As a result, LCP films are commonly used in electronic devices and packages that require high reliability and moisture resistance. LCP films are also chemically inert, making them resistant to a wide range of acids, alkalis, solvents, and chemicals. This is critical in chemical, pharmaceutical, and electronic component manufacturing and applications, as it allows for long-term exposure to corrosive environments without degradation or damage.

Fig. 7 The Special Molecular Structure of LCP Determines Its Unique and Excellent Performance Compared to Other Thermoplastic Materials

3.4 Outstanding Heat Resistance and Excellent Hot/Cold Alternating Properties

The heat resistance and hot/cold alternating properties of LCP (Liquid Crystal Polymer) films are key factors that make them stand out in high-end electronics, communications, and industrial applications. These properties enable LCP films to maintain stable physical and electrical characteristics under extreme temperature change environments, ensuring long-term device reliability and durability.

The heat resistance of LCP films is due to their unique liquid crystal state molecular structure, which imparts excellent stability to the material at elevated temperatures. With heat distortion temperatures typically ranging from 250°C to over 320°C, it is capable of operating for long periods in extremely high-temperature environments without significant physical deformation or performance degradation. This high-temperature stability makes LCP an ideal material for electronic and mechanical applications in high-temperature environments. LCP films maintain their excellent mechanical strength and electrical properties at high temperatures, ensuring the safety and reliability of equipment during high-temperature operation. For example, in high-frequency circuits and 5G communications equipment, LCP films maintain a low dielectric constant and low dielectric loss, maintaining excellent signal transmission performance even at high temperatures. LCP materials are self-extinguishing and can be quickly extinguished even when exposed to a fire source, which makes them excellent in electronic components, automotive, aerospace, and other fields, reducing the risk of fires caused by high temperatures or electrical malfunctions. Risk of fire due to high temperatures or electrical malfunctions.

Fig. 8 "Heat Resistance of LCP Films from Liquid Crystal Molecular Structure"

LCP films also have excellent hot and cold weather properties. Cold and hot alternating properties refer to the ability of a material to maintain its physical and chemical stability when subjected to frequent temperature changes, and LCP films excel in such environments, effectively resisting mechanical stress, fatigue, and material degradation caused by drastic temperature changes.

LCP films are highly resistant to thermal shock, i.e., the material does not undergo significant dimensional changes or cracking due to thermal expansion and contraction during rapid warming and cooling. This characteristic is critical for equipment and components that need to experience frequent temperature fluctuations, such as aerospace and high-frequency electronics. At the same time, LCP films have a very low coefficient of thermal expansion (typically between 10 ppm/°C and 17 ppm/°C), which allows them to undergo hot and cold cycling without the significant dimensional changes that occur with other materials. This not only improves the durability of the material, but also prevents problems such as material deformation, cracking, or interlayer separation that can occur during temperature transitions.

In addition, the molecular arrangement of the LCP film is structured so that there is no fatigue or performance degradation after many cycles of heat or cold, and the mechanical strength and electrical properties are maintained over time. This is particularly important for high-frequency signal transmission and precision electronics, ensuring their long-term stability in extreme operating environments.

Compared to other high-performance materials such as polyimide (PI) and polytetrafluoroethylene (PTFE), LCP films not only have higher heat resistance but also perform better in terms of hot and cold alternating properties. While PI films excel in heat resistance, they have a high coefficient of thermal expansion, which makes them susceptible to dimensional instability during frequent hot and cold cycling. Although PTFE has better chemical resistance, its mechanical strength and electrical properties are not as good as those of LCP in high-frequency applications.

3.5 Excellent Mechanical Properties (High Strength, High Modulus)

LCP (Liquid Crystal Polymer) films have excellent mechanical properties, particularly high strength and high modulus, which make them excellent in applications that require resistance to mechanical stress and high loads. Its unique molecular structure gives the material extremely strong mechanical properties while maintaining lightweight and dimensional stability. The high strength of LCP films is a result of the highly ordered liquid crystalline state structure of the molecular chains, which form a regular arrangement in the tensile direction, giving excellent resistance to tensile and fracture under mechanical stresses. The tensile strengths of LCP films are typically in the range of 150 MPa to 300 The tensile strength of LCP films can typically reach 150 MPa to 300 MPa, which is much higher than that of many traditional polymers. This means that LCP films are less susceptible to fracture or deformation when subjected to mechanical stress and can effectively resist external tensile stresses. Although LCP material exhibits high strength due to its rigidity, its impact resistance is also adequate in some applications. Its ability to maintain stable mechanical properties when subjected to external shock or vibration makes it highly reliable in electronic devices, automotive electronics, and industrial applications. Despite its high strength, LCP film has a low density (approximately 1.4-1.6 g/cm³), making it a lightweight, high-performance material suitable for use in areas with stringent weight requirements, such as aerospace and consumer electronics. LCP film has an extremely high modulus, which is a measure of a material's rigidity, and as a result, LCP film exhibits excellent rigidity and deformation resistance. The Young's modulus of LCP film is typically in the range of 10 GPa. Young's modulus of LCP film is typically between 10 GPa and 25 GPa, meaning it has very little elastic deformation under stress. This property allows it to maintain a high degree of form stability in precision structures that are less susceptible to bending or deformation. The high flexural modulus of LCP film also means that it resists deformation under bending forces, which is critical for applications that require mechanical stability and fatigue resistance, such as flexible printed circuit boards (FPCs) and antennas. Due to its high modulus, LCP film exhibits minimal deformation under stress, which is particularly important in scenarios requiring high precision and dimensional retention, such as electronic component packaging, antenna materials, and micromechanical structures.

LCP films not only exhibit high strength and modulus at room temperature but also maintain their excellent mechanical properties at elevated temperatures. LCP films can maintain their high strength and modulus at elevated temperatures over 250°C without significant degradation due to the temperature increase. This makes it ideal for mechanical applications in high-temperature environments, such as high-temperature electronic equipment and automotive engine components. Strength in low-temperature environments: LCP films maintain their high strength and rigidity at low temperatures as well, and can exhibit good mechanical properties even at extreme temperatures, which is why they are used in a wide range of aerospace and military equipment, especially in low-temperature and high-stress environments.

Fig. 9 LCP Is Used in Avionics Due to Its Mechanical Strength and Electrical Properties

Table 2. Key Properties Of LCP (Liquid Crystal Polymer) Films

Property | Values |

Dielectric Constant (Dk) | 2.9 - 3.5 |

Dielectric Loss (Df) | 0.002 - 0.004 |

Water Absorption | < 0.04% |

Coefficient of Thermal Expansion (CTE) | 10 - 17 ppm/°C |

Operating Temperature Range | -50°C to over 250°C |

Tensile Strength | 150 - 300 MPa |

Young's Modulus | 10 - 25 GPa |

Key Applications | High-frequency applications, 5G communications, Flexible circuits, Aerospace |

4 Conclusion

LCP films are leading materials for high-performance applications because of their unique combination of properties. LCP films have consistently low dielectric constants and losses, extremely low water absorption, and low coefficients of thermal expansion to maintain performance integrity even in harsh environments. LCP films offer excellent dimensional stability, high strength, and excellent resistance to temperature fluctuations, making them suitable for a variety of applications, including high-frequency circuit boards, flexible circuits, and precision electronic packaging. LCP films offer balanced mechanical, thermal, and dielectric properties compared to other high-performance materials, ensuring reliability under extreme conditions. As electronic devices continue to move to higher frequencies and miniaturization, LCP films will play a key role in supporting these technological advances.

Stanford Advanced Materials (SAM) is a key provider of high-quality LCP films, supporting these critical applications with reliable material solutions.

Related Reading:

Main-chain Liquid Crystalline Polymers for Optical Applications