Electrocaloric Coefficient and Cooling Devices

Introduction to the Electrocaloric Coefficient

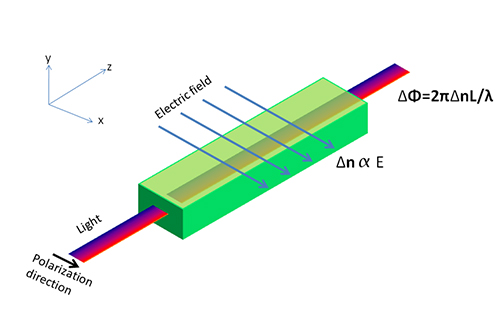

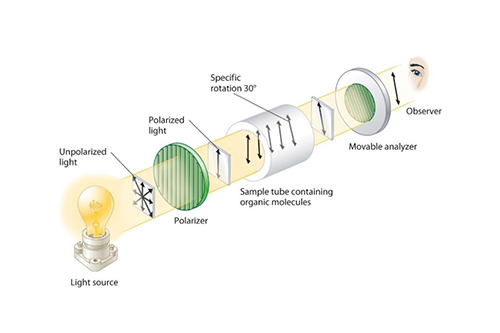

The electrocaloric coefficient is a critical parameter that measures the strength of the electrocaloric effect in a material. It is defined as the change in temperature per unit change in the electric field applied to the material. A higher electrocaloric coefficient indicates a more significant temperature change, which is desirable for effective cooling applications. This coefficient helps in comparing different materials and selecting the most suitable ones for specific cooling technologies.

Applications in Electrocaloric Cooling

Electrocaloric cooling has several promising applications, particularly in areas where traditional cooling methods are less effective or sustainable. These applications include:

- Electronic Devices: Managing heat in smartphones, laptops, and other electronic gadgets to enhance performance and longevity.

- Automotive Systems: Providing efficient climate control in vehicles with reduced energy consumption.

- Medical Devices: Ensuring precise temperature control in medical equipment, improving reliability and patient safety.

- Space Technology: Offering lightweight and efficient cooling solutions for spacecraft and satellites.

Factors Influencing the Electrocaloric Coefficient

Several factors affect the electrocaloric coefficient, including:

- Material Properties: The intrinsic characteristics of the material, such as its dielectric constant and phase transitions, play a significant role.

- Temperature Range: The effectiveness of the electrocaloric effect varies with temperature, often peaking near phase transition points.

- Electric Field Strength: The magnitude of the applied electric field directly influences the extent of the temperature change.

- Material Thickness: Thinner materials can respond more rapidly to electric field changes, enhancing the electrocaloric effect.

Electrocaloric Materials and Their Properties

The choice of material is crucial for maximizing the electrocaloric effect. Some commonly studied electrocaloric materials include:

|

Material Type |

Electrocaloric Coefficient (K/(kV/cm)) |

Operating Temperature (°C) |

Key Properties |

|

0.3 |

25-120 |

High dielectric constant, ferroelectric |

|

|

Lead Titanate |

0.25 |

30-110 |

Strong electrocaloric response |

|

0.2 |

20-80 |

Flexible, lightweight |

|

|

(Ba,Sr)TiO₃ |

0.28 |

50-150 |

Tunable dielectric properties |

These materials are selected based on their ability to exhibit significant temperature changes under applied electric fields, making them suitable candidates for various cooling technologies.

Frequently Asked Questions

What is the electrocaloric effect?

The electrocaloric effect is the reversible temperature change in a material when an electric field is applied or removed.

How does the electrocaloric coefficient impact cooling applications?

A higher electrocaloric coefficient means a more significant temperature change, making the material more effective for cooling purposes.

What materials are best suited for electrocaloric cooling?

Materials like Barium Titanate, Lead Titanate, and Polyvinylidene Fluoride (PVDF) are commonly used due to their strong electrocaloric responses.

Can electrocaloric cooling replace traditional refrigeration?

Electrocaloric cooling offers a more energy-efficient and environmentally friendly alternative, but it is still under development for widespread use.

What factors can enhance the electrocaloric effect in materials?

Increasing the electric field strength, optimizing material properties, and operating near phase transition temperatures can enhance the electrocaloric effect.