Dielectric Strength: Formula and Test Methods

What Is Dielectric Strength

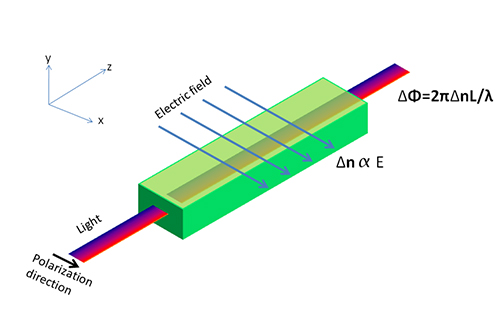

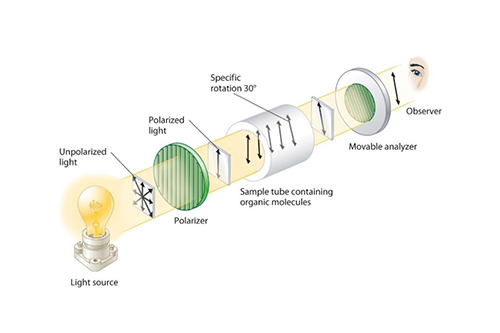

Dielectric strength refers to the maximum electric field that a material can withstand without experiencing electrical breakdown. It is a critical property for materials used in insulating applications, ensuring safety and reliability in electrical systems.

Dielectric Constant vs. Dielectric Strength

While dielectric strength measures the ability to resist electrical breakdown, the dielectric constant indicates a material's ability to store electrical energy. Both properties are important but serve different purposes in material selection and application.

Standard Tests to Calculate Dielectric Strength

The standard tests commonly used to calculate dielectric strength are:

- ASTM D149-20: This is a standard test method to measure the dielectric breakdown voltage and dielectric strength of insulating materials, including electrical cables, wires, and coatings. It determines how much voltage an insulating material can withstand before breaking down.

- IEC 60243-1:2013: This international standard is used to measure the dielectric strength of solid insulating materials such as plastics, rubbers, and ceramics. It helps determine the material’s ability to resist electrical breakdown when subjected to a high electric field.

Both standards are widely recognized and used in the testing of materials for electrical insulation to ensure they meet safety and performance criteria in electrical and electronic applications.

Examples of Insulation Materials

Insulation materials are used to prevent the flow of electricity, heat, or sound. In electrical applications, these materials help protect conductors from electrical faults and ensure safety.

- Polyethylene (PE): A widely used insulating material, particularly in wires and cables due to its low cost, flexibility, and good dielectric properties.

- Polyvinyl Chloride (PVC): Common in electrical wiring and cables, PVC offers good electrical insulation, flame resistance, and is relatively inexpensive.

- Rubber: Both natural and synthetic rubber materials like EPDM (ethylene propylene diene monomer) are used as insulation due to their flexibility, water resistance, and durability.

- Teflon (PTFE): Known for its excellent dielectric properties, high-temperature resistance, and chemical stability. Used in high-performance electrical components.

- Silicone: Used in high-temperature applications and for flexible cables, silicone offers excellent insulation and resistance to heat, ozone, and chemicals.

- Fiberglass: Often used in high-voltage applications, fiberglass is an excellent insulator and is resistant to high temperatures and electrical stress.

- Mica: A mineral-based insulator that’s used in high-temperature environments, often found in electric motors, transformers, and other high-voltage electrical equipment.

- Polyimide (Kapton): A flexible, high-performance insulation material used in aerospace and electronics due to its ability to withstand extreme temperatures.

- Enameled Wire (Magnet Wire): A wire coated with a thin layer of insulation, typically made of a polymer, used in transformers, electric motors, and coils.

- Paper and Oil Insulation: Typically used in older electrical systems, such as transformers, paper soaked in oil provides excellent insulation and cooling properties.

- Ceramics: Used in high-voltage and high-temperature applications, ceramic materials like alumina provide excellent electrical insulation and mechanical strength.

Applications in Various Industries

- Power Generation: Insulation in transformers and generators.

- Electronics: Insulating components in circuit boards.

- Telecommunications: Protecting cables and transmission lines.

Frequently Asked Questions

What factors affect dielectric strength?

Temperature, humidity, material thickness, and the presence of impurities can influence dielectric strength.

How is dielectric strength different from electrical conductivity?

Dielectric strength measures a material's ability to resist electrical breakdown, while electrical conductivity assesses how easily electricity flows through a material.

Why is dielectric strength important in capacitors?

High dielectric strength allows capacitors to store more energy without the risk of breakdown, enhancing their efficiency and reliability.

Can dielectric strength change over time?

Yes, factors like aging, environmental exposure, and mechanical stress can degrade a material's dielectric strength.

How do different testing methods impact the measurement of dielectric strength?

Different testing methods, such as AC, DC, or impulse testing, can simulate various operating conditions, providing a comprehensive understanding of a material's performance.