D33 Values in Piezoelectric Crystals: Implications for Practical Applications

1 Introduction

Piezoelectric materials can generate an electric field when deformation occurs by external force, and deformation occurs when the electric field is applied, which realizes the mutual conversion of mechanical energy and electric energy in the process, and thus has a wide range of applications in electronic equipment and optoelectronic fields. For piezoelectric materials, the piezoelectric constant is the most common and intuitive performance expression, which reflects the material for the mechanical stress or electric field and the direction of the generated electric field or deformation of the size of the relationship. One of the most commonly used characterization values is the d33 value, which will be discussed in this paper from the point of view of its relationship with the properties and applications of various piezoelectric crystals.

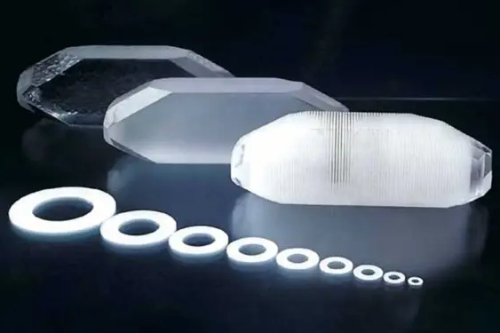

Fig. 1 Quartz Crystals and Wafers

2 Overview of The Piezoelectric Effect

2.1 Piezoelectric Crystals and The Piezoelectric Effect

Piezoelectric crystals are crystalline materials that have a piezoelectric effect. The piezoelectric effect is a physical phenomenon that occurs when certain materials are deformed by external forces, which produces a charge separation within the material, thus generating an electric field at both ends of the material. Conversely, when an electric field is applied to these materials, the material undergoes mechanical deformation. The piezoelectric effect is mainly found in certain crystals without a centrosymmetric structure, such as barium titanate (BaTiO3), lead zirconate titanate (PZT), and quartz (SiO2).

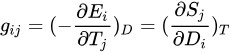

2.2 Piezoelectric Constants

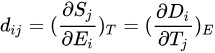

Piezoelectric constants are a set of parameters that characterize the ability of a piezoelectric material to convert a motor under mechanical stress and electric field. They are the key coefficients connecting electrical and mechanical quantities, specifically reflecting a material's mechanical deformation or charge distribution under an applied electric field or mechanical stress. These constants are usually denoted as dij, gij, eij, etc., with dij being the most common.

1. dij constant (strain constant): used to describe the relationship between the strain produced by the material under the action of an applied electric field and the strength of the electric field. I and j represent the direction of the applied electric field and the direction of the strain produced.

2. The gij constant (stress constant) describes the relationship between the electric field generated by the material under mechanical stress and the stress. I and j represent the direction of the applied mechanical stress and the direction of the generated electric field, respectively.

3. The eij constant (stress-charge constant) describes the relationship between the charge density generated by the piezoelectric material under mechanical stress and the stress. I and j represent the direction of the applied stress and the direction of the generated charge, respectively.

2.3 D33 Constant

The value of d33 represents the proportionality between the strain produced by the material in the direction of polarization (usually 3-direction) and the strength of the applied electric field when the electric field is applied to the material in that direction. A higher d33 value means that the material can generate a larger mechanical strain when an electric field is applied, or a stronger electric field when a mechanical stress is applied. This indicates that the material is efficient in motor conversion and can convert electrical energy to mechanical energy or mechanical energy to electrical energy more efficiently.

The magnitude of the d33 value has a direct impact on the performance of the piezoelectric material and accordingly affects the effectiveness of the piezoelectric material in applications. In piezoelectric sensors, the higher the d33 value, the higher the sensitivity and responsiveness of the material, for the sensor received by the external mechanical stress or pressure can produce a more obvious electrical signal. In piezoelectric actuators, materials with higher d33 values can generate greater stresses or displacements when an electric field is applied, making them suitable for applications that require greater precision control and high-power output. In piezoelectric energy harvesters, materials with high d33 values can more efficiently convert mechanical energy in the environment into electrical energy, improving the efficiency of energy utilization.

3 Factors Affecting D33 Values

3.1 Crystal Structure

The symmetry and lattice constants of the crystal have an important influence on the d33 value. Low-symmetry crystals (e.g., monoclinic or triclinic) usually have higher piezoelectric coefficients because they allow for greater lattice distortion. Larger lattice constants tend to imply larger deformable space, which may improve the piezoelectric properties.

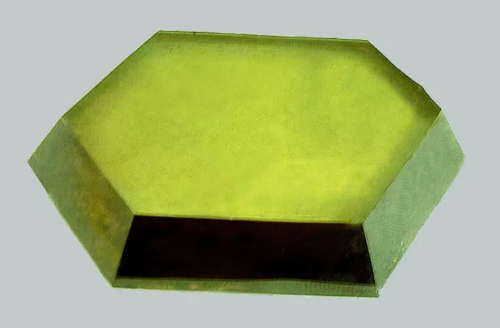

Fig. 2 Crystals with Piezoelectricity Have Lower Symmetry

3.2 Material Composition

The doping of different elements in piezoelectric materials can significantly affect the d33 value. For example, in PZT, the piezoelectric properties can be optimized by adjusting the ratio of titanium to zirconium. In addition, the stoichiometric ratio in the material affects the d33 value. Deviation from the ideal stoichiometric ratio may lead to crystal defects, affecting the piezoelectric properties.

3.3 Processing

The sintering temperature and time of piezoelectric ceramic materials affect their microstructure and grain size, which in turn affects the d33 value. Proper sintering conditions can optimize grain size and reduce grain boundary defects. Polarization treatment is a key step to enhance the piezoelectric properties, by applying an electric field at high temperatures, the dipoles inside the material are oriented in the same direction, thus improving the d33 value.

3.4 Microstructure

The grain size has a significant effect on the d33 value. In general, intermediate grain size (micron level) is favorable for improving piezoelectric properties, while too large or too small grain size leads to a decrease in d33 values. Grain boundary defects affect the piezoelectric properties, and the reduction of grain boundary defects helps to improve the d33 values. Stress concentration and charge accumulation at grain boundaries reduce piezoelectric properties.

3.5 External Conditions

The temperature has a significant effect on the d33 value. Most piezoelectric materials exhibit optimal piezoelectric properties near the Curie temperature, but the d33 value decreases at too high or too low a temperature. External mechanical stresses and strains can also affect d33 values. In some materials, proper pre-stressing can improve piezoelectric properties, but too much stress can lead to cracking or degradation of the material.

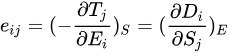

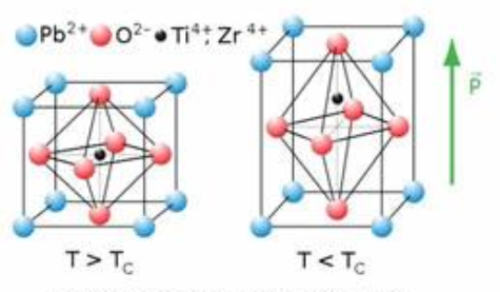

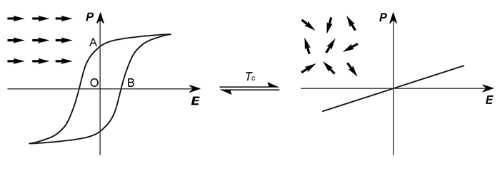

3.6 Ferroelectricity of Materials

The ferroelectric domain structure of a piezoelectric material has a direct effect on the d33 value. Larger domain wall motion improves the piezoelectric response of the material. The relationship between the direction of polarization and the stress direction of the material also affects the d33 value, and the best piezoelectric response is usually obtained when the direction of polarization is the same as the stress direction.

Fig. 3 Schematic Diagram of Electric Dipole Arrangement and Electrodeposition Response Curves in Ferroelectric Phase Transitions

3.7 Electric Field and Frequency

The strength and direction of the applied electric field have a significant effect on the d33 value. An appropriate electric field can enhance the piezoelectric response of a material. The frequency of the applied electric field also affects the d33 value, with certain materials exhibiting resonance-enhanced piezoelectric properties at specific frequencies.

4 Properties and Applications of Common Piezoelectric Materials

4.1 Quartz

Quartz (SiO2) is a naturally occurring piezoelectric material widely used in various electronic and optical devices. It is a hexagonal crystal system with high symmetry, and its piezoelectric properties depend on crystal orientation and stress direction. Quartz typically has d33 values around 2 - 3 pC/N, which is relatively low. Despite the relatively low value of the piezoelectric constant d33 of quartz, its unique physical properties and excellent stability make it irreplaceable in specific fields.

Quartz has excellent physical and chemical stability and is capable of maintaining stable piezoelectric properties under a variety of environmental conditions. In addition, quartz's high-quality factor makes it superior to other materials in oscillators and resonators, providing higher frequency stability and lower energy loss. Quartz's low-temperature coefficient ensures frequency stability over a wide temperature range, an important advantage in high-precision applications. These properties make quartz widely used even though it has a relatively low d33 value.

Quartz crystals are widely used in oscillators and resonators in electronic devices to provide stable frequency references. The high-quality factor and low-temperature coefficient of quartz ensures frequency stability and low loss over long periods. Quartz is also used in piezoelectric sensors for measuring force, pressure, and acceleration. Quartz sensors excel in accuracy and long-term stability, making them suitable for high-precision measurements and long-term monitoring. Quartz is also used in optical modulators and fiber optic communication devices. Quartz's high transparency and low absorption give it important applications in optics, especially in laser and fiber optic communications.

Fig. 4 Quartz Wafer Rings

4.2 Barium Titanate

Barium titanate (BaTiO3) is a common piezoelectric ceramic material that has attracted much attention in many applications due to its excellent piezoelectric properties and high d33 values. Barium titanate has a chalcogenide structure (ABO3), and this structure exhibits good piezoelectricity and ferroelectricity in a specific temperature range. The d33 value for barium titanate is typically around 100 - 200 pC/N. This is a relatively high value. This is a relatively high value, indicating that barium titanate is capable of producing significant mechanical strain when an electric field is applied.

Barium titanate with a high d33 value can significantly improve the material's motor conversion efficiency. Barium titanate has ferroelectricity in a specific temperature range, enabling it to maintain stable piezoelectric properties over a wide temperature range. Barium titanate materials have excellent chemical stability and mechanical strength, making them suitable for long periods of use in harsh environments. Barium titanate ceramic materials are easy to process and mold, suitable for mass production, and widely used in industrial fields.

Due to its high d33 value and excellent piezoelectric properties, barium titanate is widely used in a variety of fields. Barium titanate is used to manufacture pressure sensors, acceleration sensors, and vibration sensors. The high d33 value of barium titanate enables these sensors to detect mechanical stress and vibration sensitively, providing susceptible and high-resolution measurements. Barium titanate is also used to manufacture precision actuators, such as microdisplacement actuators and ultrasonic transducers, capable of generating large mechanical deformations when an electric field is applied, enabling precise control and high-power output. The characteristics of barium titanate make it widely used in energy harvesters to convert mechanical energy (e.g., vibration, pressure) in the environment into electrical energy. Improved energy conversion efficiency enables energy harvesters to collect and store energy more efficiently for self-powered devices and wearables. High dielectric constant and good piezoelectric properties enable barium titanate capacitors to excel in high-frequency and high-voltage applications, providing high energy density and stability.

4.3 Lead Zirconate Titanate (PZT)

PZT has a strong piezoelectric effect, which produces significant charge separation under mechanical stress, creating an electric field; conversely, it induces significant mechanical deformation under an applied electric field. PZT has a chalcogenide structure (ABO3), and its piezoelectric and ferroelectric properties can be tuned by varying the ratio of Zr and Ti.

The d33 values of PZT are usually in the range of 200 - 600 pC/N, which makes PZT one of the materials with high piezoelectric properties. The higher d33 values imply that PZT is capable of generating significant mechanical strain when an electric field is applied in its polarization direction (usually 3-direction). This indicates that PZT is very efficient in motor conversion. The higher d33 value that PZT has significantly improved the material's motor conversion efficiency, allowing it to excel in high-performance piezoelectric applications. By adjusting the ratio of zirconium to titanium, the piezoelectric and ferroelectric properties of PZT can be optimized for different applications. PZT materials have excellent chemical stability and mechanical strength and can be used in harsh environments for long periods. PZT ceramics are easy to process and mold, which makes them suitable for large-scale production and are widely used in industrial applications.

Fig. 5 Lead Zirconate Titanate Ceramic Sheet

4.4 Zinc Oxide (ZnO)

Zinc oxide (ZnO) is a semiconductor material with excellent piezoelectric properties, and its d33 value is usually in the range of 5-12 pC/N. Although ZnO has a higher d33 value than ZnO, it has a lower d33 value than ZnO. Although the d33 value of ZnO is relatively low compared to conventional piezoelectric materials such as lead zirconate titanate (PZT) and barium titanate (BaTiO3), its unique properties make it promising for a wide range of applications in many fields. Zinc oxide has a hexagonal fibrillated zincite structure, a structure that confers excellent piezoelectric properties and high electromechanical coupling coefficients. Zinc oxide is capable of generating significant mechanical strain when an electric field is applied in the direction of its polarization (usually in the c-axis direction), which is not as strong as some high-performance piezoelectric ceramics, but is sufficient for some specific applications.

The piezoelectric properties of zinc oxide make it excellent for use in areas such as nanogenerators, piezoelectric sensors, and surface acoustic wave devices. In nanogenerators, ZnO nanowire arrays can effectively convert mechanical energy (e.g., vibration and compression) into electrical energy, and despite their low d33 values, energy harvesting efficiencies can be significantly improved through nanostructure optimization and array design. In piezoelectric sensors, the high sensitivity and good frequency response of zinc oxide make it suitable for detecting small mechanical stresses and pressure changes. In addition, zinc oxide is widely used in surface acoustic wave devices, where its excellent piezoelectric and semiconductor properties enable high-performance acoustic wave signal processing.

Zinc oxide's strengths also include its good chemical stability and biocompatibility, giving it great potential in the biomedical field. For example, zinc oxide nanowire sensors can be used for biomolecular detection and cellular mechanics studies, combining their piezoelectric properties and semiconductor characteristics to enable highly sensitive and selective detection. The applications of zinc oxide are also expanding in the fields of environmental sensing and energy harvesting. Despite its relatively low d33 value, the versatility and tunability of zinc oxide make it a valuable piezoelectric material for a variety of applications.

Fig. 6 Semiconductor Crystal Zinc Oxide

4.5 Lithium Niobate (LiNbO₃)

Lithium Niobate (LiNbO3) is a ferroelectric material with significant piezoelectric properties, with d33 values typically in the 6-20 pC/N range. Although the d33 values of LiNbO3 are not as high as those of some high-performance piezoelectric ceramics (e.g., lead zirconate titanate), its unique physical properties make it important for applications in optoelectronic and acoustic devices. Lithium niobate has a tripartite crystal system structure, which gives it excellent piezoelectric and optical properties. Lithium niobate is capable of generating significant mechanical strain when an electric field is applied in the direction of polarization, usually in the c-axis direction.

The piezoelectric properties of lithium niobate allow it to excel in optical modulators, surface acoustic wave devices, and nonlinear optical devices. In optical modulators, lithium niobate can realize high-speed and precise optical signal modulation due to its high electro-optical coefficient and good piezoelectric properties; in acoustic surface wave devices, lithium niobate makes use of its high acoustic wave propagation speed and piezoelectric properties to realize highly efficient acoustic wave signal processing and transmission, which is widely used in wireless communications and signal filtering. In addition, lithium niobate is also widely used in nonlinear optical devices. Its excellent nonlinear optical properties make it an ideal material for frequency conversion and optical parametric oscillators.

The advantages of lithium niobate also include its high mechanical strength, chemical stability, and wide transparency window, allowing it to maintain good performance in a wide range of harsh environments. This gives lithium niobate great potential for aerospace, military, and industrial applications. For example, in aerospace, lithium niobate sensors can be used for high-precision force and pressure detection; in the military, the optical and piezoelectric properties of lithium niobate can be used in advanced optoelectronic countermeasures and communication equipment. In industrial applications, the high-temperature stability and radiation resistance of lithium niobate make it suitable for monitoring and control equipment in harsh environments. Although lithium niobate has a relatively low D33 value, its versatility, and excellent optoelectronic properties make it a valuable piezoelectric material in a variety of applications.

Fig. 7 LiNbO3 Crystals

4.6 Lithium Tantalate (LiTaO₃)

Lithium tantalate (LiTaO3) is an important piezoelectric material with d33 values typically in the range of 5-18 pC/N. The d33 values of LiTaO3 are in the range of 5-18 pC/N. Although the d33 value of LiTaO3 is slightly lower than that of some high-performance piezoelectric ceramics (e.g., lead zirconate titanate), its unique physical and chemical properties make it widely used in optoelectronic and acoustic devices. Lithium tantalate has a tripartite crystal system structure, which gives it excellent piezoelectric and optical properties. When an electric field is applied in its polarization direction (usually the c-axis direction), lithium tantalate is capable of generating significant mechanical strain. Although d33 values are relatively low, they are sufficient for many optoelectronic and acoustoelectronic applications.

The piezoelectric properties of lithium tantalate allow it to excel in surface acoustic wave devices, optical modulators, and nonlinear optical devices. In acoustic surface wave devices, lithium tantalate utilizes its high acoustic wave propagation speed and good piezoelectric properties to achieve highly efficient acoustic wave signal processing and transmission, which is widely used in wireless communications and signal filtering; in optical modulators, lithium tantalate can achieve high-speed and precise optical signal modulation by its high electro-optical coefficient and good piezoelectric properties; in addition, lithium tantalate is also widely used in nonlinear optical devices, and its Excellent nonlinear optical properties make it an ideal material for frequency conversion and optical parametric oscillators.

The advantages of lithium tantalate also include its high mechanical strength, chemical stability, and wide transparency window, allowing it to maintain good performance in harsh environments. This gives lithium tantalate great potential for use in aerospace, military, and industrial applications. For example, in aerospace, lithium tantalate sensors can be used for high-precision force and pressure detection; in the military, lithium tantalate's optical and piezoelectric properties can be used in advanced optoelectronic countermeasures and communications equipment; and in industrial applications, lithium tantalate's high-temperature stability and resistance to radiation make it suitable for use in harsh environments for monitoring and control equipment. Despite its relatively low d33 value, the versatility and excellent optoelectronic properties of lithium tantalate make it a valuable piezoelectric material in a variety of applications.

Fig. 8 LiTaO3 Crystals

5 Conclusion

The piezoelectric effect and its associated constants (especially the d33 value) directly affect the performance of piezoelectric materials and determine their efficiency and effectiveness in applications such as sensors, actuators, and energy harvesters. Factors affecting the d33 value include crystal structure, material composition, processing, microstructure, external conditions, ferroelectricity of the material, and applied electric field and frequency, which work together in a variety of ways to determine the final properties of piezoelectric materials.

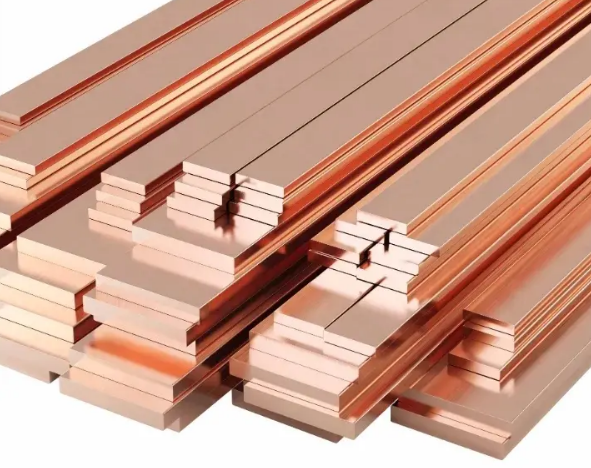

Stanford Advanced Materials (SAM) is committed to providing top-tier piezoelectric materials that maximize the potential of d33 values, ensuring high performance and reliability in various practical applications.

Related Reading: