- Products

- Categories

- Blog

- Podcast

- Application

- Document

CF2143 Ceramic Fiber

| Catalog No. | CF2143 |

| Material | Al2O3, SiO2, ZrO2, Cr2O3 |

| Appearance | White/blue-green fiber |

Stanford Advanced Materials (SAM) has over 2 decades of experience supplying refractory ceramic fiber of high quality at competitive prices. We are also able to customize this product as per your specifications.

Related products: Ceramic Fiber Board, Ceramic Fiber Paper, Light Mullite Brick

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

YSZ1870 Yttria Stabilized Zirconia Nanopowder( YTZP/YSZ Nanopowder)

GR0191 Pyrolytic Graphite Crucible

ZC0516 Yttria Stabilized Zirconia (YSZ) Grinding Media

SC0892 High Purity Silicon Carbide Powder (SiC Powder) (CAS No.409-21-2)

SC0893 Silicon Carbide Bearing (SiC Bearing)

AC2467 (Discontinued) Aluminum Oxynitride Transparent Ceramic, ALON

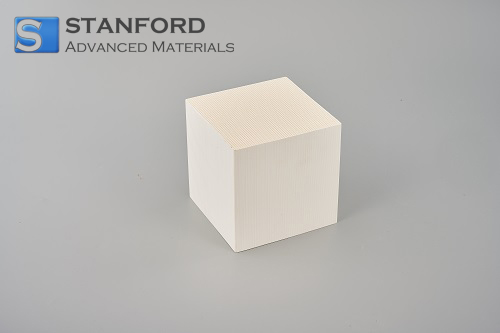

AC2691 (Discontinued) Alumina Ceramic Honeycomb

.jpg)

CM4013 (Discontinued) Ammonia Synthesis Catalyst (Iron-Cobalt)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!