- Products

- Categories

- Blog

- Podcast

- Application

- Document

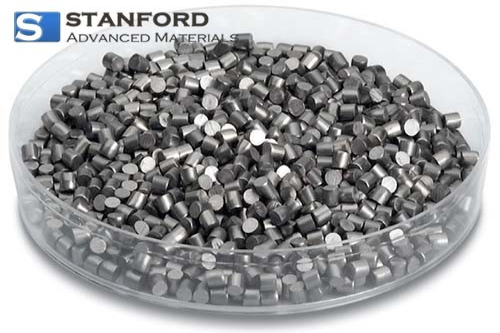

BR5746 Boron Filament

| Catalog No. | BR5746 |

| CAS Number | 7440-42-8 |

| Material | Boron |

| Shape | Filament |

| Density | 2.34 g/cm3 |

| Purity | 99% |

Boron Filament is a type of high-strength, high-stiffness fiber made from boron. Stanford Advanced Materials (SAM) boasts extensive experience in providing Boron Filament with both high purity and competitive pricing.

Related products: Bor on Rod, Boron Foil, Boron Granule

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

BR0068 Niobium Boride Powder, NbB Powder (CAS No. 12045-19-1)

VD0538 Boron (B) Evaporation Materials

VD0748 Boron Nitride (BN) Evaporation Materials

VD0760 Boron Carbide (B4C) Evaporation Materials

VD0829 Aluminum Boron (AlB2) Evaporation Materials

VD0830 Cerium Boride (CeB6) Evaporation Materials

VD0831 Chromium Boride (CrB2) Evaporation Materials

BC2727 (Discontinued) Boron Bromide Powder (CAS: 10294-33-4)

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!