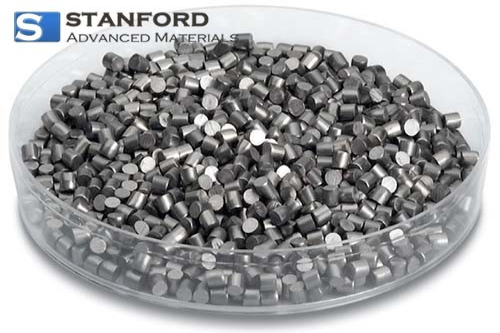

VD0538 Boron (B) Evaporation Materials

| Catalog No. | VD0538 |

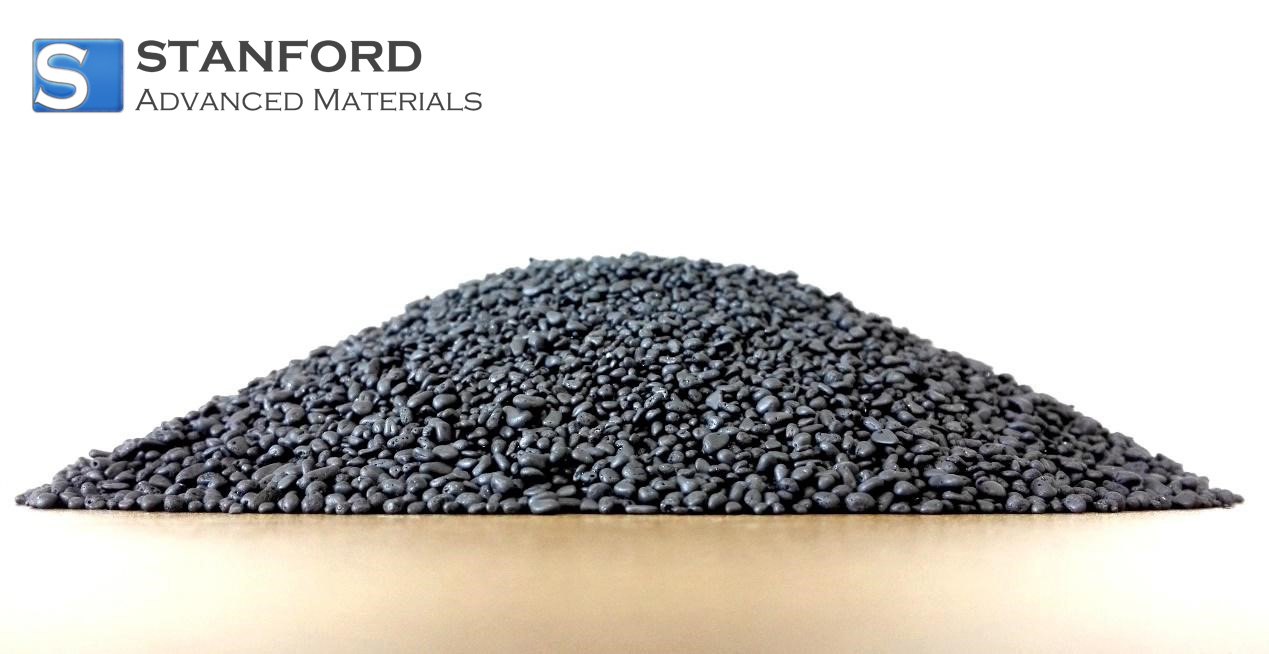

| Material | Boron (B) |

| Purity | 99.5% |

| Shape | Powder/ Granule/ Custom-made |

| MSDS/SDS |

Stanford Advanced Materials (SAM) is a leading manufacturer and supplier of high purity Boron Evaporation Materials and a wide variety of evaporation materials. We offer our evaporation materials in powder and granule form. Customized forms are also available upon request.

Related products: Antimony (Sb) Evaporation Materials, Aluminum (Al) Evaporation Materials

Description:

Boron Evaporation Materials are essential in thin film deposition processes, boasting unique properties pivotal for various applications. Characterized by high purity and controlled evaporation rates, they ensure precise film deposition onto substrates, facilitating uniform and defect-free film formation. Boron Evaporation Materials exhibit excellent thermal stability, enabling them to withstand high temperatures during deposition. Widely utilized in semiconductor devices, optical coatings, and research laboratories, they contribute significantly to advancements in thin film technology. With their versatility and reliability, Boron Evaporation Materials play a crucial role in industries requiring thin film fabrication, offering consistent performance and enabling technological innovations.

Specification:

|

Material |

Boron |

|

Appearance |

Black, Semi-metallic |

|

Melting Point (°C) |

2,079 |

|

Thermal Conductivity |

27W/m.K |

|

Coefficient of Thermal Expansion |

6 x 10-6/K |

|

Theoretical Density (g/cc) |

2.34 |

Applications:

1. Semiconductor devices: Materials used as semiconductor devices for the preparation of boride films, doping layers, and electrodes, e.g., in electronic devices, optoelectronic devices, and solar cells.

2. Optical coatings: Thin films for the preparation of optical components, such as optical mirrors, optical filters, and lenses, to regulate the transmission, reflection, and absorption of light.

3. Protective Coatings: Used as a component of protective coatings to improve surface hardness, wear, and corrosion resistance, e.g., in aerospace, automotive, and tool manufacturing.

4. Material Reinforcement: Used as reinforcing agents for metal matrix composites, ceramic, and polymer materials to improve strength, hardness, and wear resistance.

5. Materials Research: Used as experimental materials and reference standards in materials science and surface science research to study thin film growth, surface properties, and phase transitions of materials.

Packaging:

Our evaporation materials are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

FAQs

Q1: What are Boron Evaporation Materials?

A1: Boron (B) evaporation materials are high-purity boron in forms such as pellets, granules, or pieces, used in physical vapor deposition (PVD) processes. They are utilized to create thin films with excellent hardness, chemical resistance, and thermal stability.

Q2: What are the main applications of Boron Evaporation Materials?

A2: Boron evaporation materials are widely used in:

Semiconductors (thin-film deposition in microelectronics)

Optical coatings (infrared and laser optics)

Protective coatings (wear-resistant and anti-corrosion layers)

Nuclear applications (neutron absorption coatings)

Advanced research (specialized thin-film studies in R&D)

Q3: What are the key benefits of using Boron Evaporation Materials?

A3: High hardness – Provides wear-resistant coatings.

Excellent chemical stability – Resistant to oxidation and corrosion.

High-temperature resistance – Suitable for extreme environments.

Neutron absorption properties – Useful in nuclear technology.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!