Aluminum: Element Properties and Uses

Description

Aluminum is a lightweight, corrosion-resistant metal commonly used in industries like construction, transportation, and packaging. It is abundant and versatile in its applications.

Introduction to the Element

Aluminum (symbol Al, atomic number 13) is a silvery-white metal that is widely used across many industries due to its unique properties. It is the third most abundant element in the Earth's crust, found primarily in minerals like bauxite. Aluminum is non-ferrous, meaning it does not contain iron, which gives it resistance to rust and corrosion. It was first isolated in 1825 by Hans Christian Ørsted, but it wasn’t until the 19th century that aluminum became a commercially viable material.

Its combination of light weight, strength, and non-corrosive nature makes aluminum essential for a variety of applications, ranging from the automotive sector to food packaging.

Chemical Properties Description

Aluminum is a highly reactive metal, but it forms a protective oxide layer on its surface when exposed to air. This layer prevents further oxidation and corrosion. Chemically, aluminum is reactive with acids, bases, and other substances, which makes it important in various chemical reactions.

Aluminum has an oxidation state of +3 in most of its compounds. When exposed to air, it reacts with oxygen to form aluminum oxide (Al₂O₃), a hard, transparent layer that provides a protective shield. This oxide is insoluble in water and resists corrosion, making aluminum highly durable despite its reactivity.

Physical Properties

Aluminum has several distinctive physical properties that make it highly useful in different industries. Below is a table summarizing these properties:

|

Property |

Description |

|

Atomic Number |

13 |

|

Density |

2.70 g/cm³ |

|

Melting Point |

660.3°C |

|

2470°C |

|

|

Conductivity |

High electrical and thermal conductivity |

|

Appearance |

Silvery-white, shiny |

|

Malleability |

Highly malleable and ductile |

|

Strength |

Moderate tensile strength |

|

Corrosion Resistance |

High due to oxide layer |

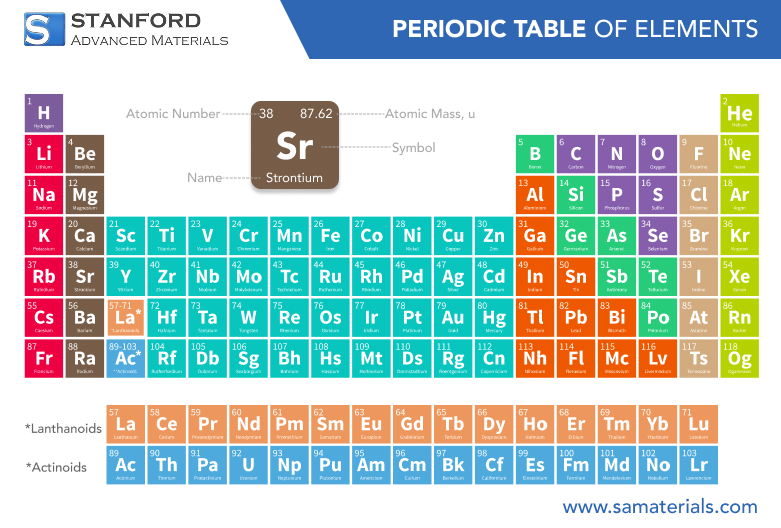

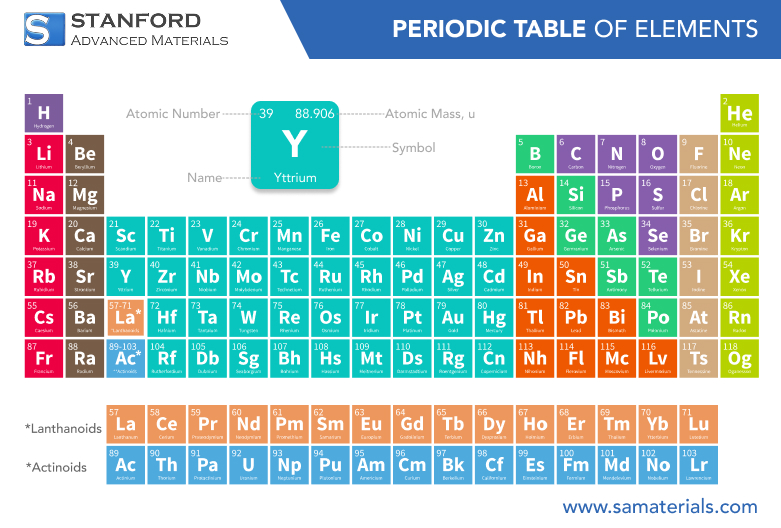

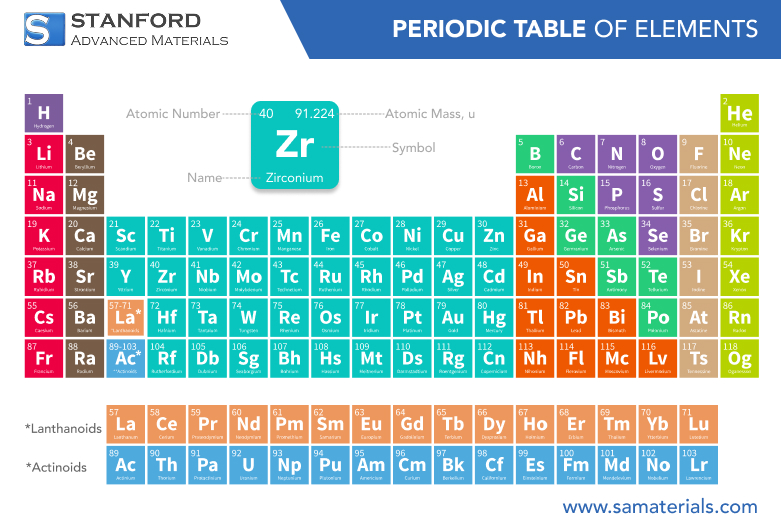

These physical characteristics make aluminum particularly useful for applications where strength, weight, and durability are crucial factors. For more information, please check Stanford Advanced Materials (SAM).

Common Uses

Aluminum is widely used due to its advantageous properties such as lightweight, corrosion resistance, and ease of fabrication. Some common uses of aluminum include:

- Construction: Aluminum is used for window frames, roofing, siding, and doors due to its strength and resistance to corrosion.

- Automotive: In the automotive industry, aluminum is used for body panels, wheels, engine blocks, and radiators to reduce vehicle weight and improve fuel efficiency.

- Aerospace: Aircraft parts, such as wings and fuselages, are often made of aluminum because of its strength-to-weight ratio.

- Packaging: Aluminum is commonly used for beverage cans, food containers, and foil because it is lightweight, durable, and easy to recycle.

- Electrical: Aluminum is used in electrical conductors and cables due to its high conductivity.

Preparation Methods

Aluminum is primarily extracted from bauxite through a refining process called the Bayer Process. The Bayer Process involves crushing the bauxite ore and treating it with sodium hydroxide, which separates the aluminum oxide from the impurities. The aluminum oxide is then reduced to aluminum metal via the Hall-Héroult Process, an electrochemical process that requires large amounts of electricity.

Aluminum can also be recycled from old aluminum products, which requires less energy than refining it from bauxite, making aluminum recycling a highly sustainable practice.

Related Industrial Products

- Aluminum Alloys: Aluminum is often alloyed with other metals such as copper, magnesium, and zinc to improve its mechanical properties. These alloys are used in industries requiring higher strength and durability.

- Aluminum Foil: Used in packaging, insulation, and even as a cooking material, aluminum foil is a product derived from thin sheets of aluminum.

- Aluminum Oxide: An important industrial material used as an abrasive and in the production of aluminum metal.

Frequently Asked Questions

What is the most common use of aluminum?

Aluminum is most commonly used in construction, automotive, aerospace, and

packaging industries due to its lightweight and corrosion-resistant properties.

How is aluminum extracted from bauxite?

Aluminum is extracted from bauxite through the Bayer Process, which involves

refining the ore to produce aluminum oxide, followed by electrolysis in the

Hall-Héroult Process to obtain the metal.

Is aluminum recyclable?

Yes, aluminum is highly recyclable and can be reused multiple times without

losing quality, making it one of the most sustainable materials.

What makes aluminum resistant to corrosion?

Aluminum forms a thin oxide layer on its surface when exposed to air, which

protects it from further corrosion and increases its durability.

Is aluminum a good conductor of electricity?

Yes, aluminum has excellent electrical conductivity and is widely used in power

transmission lines and electrical cables.