PE6498 Polyimide Film Aramid Nonwoven Felt Composite Sleeve

| Catalog No. | PE6498 |

| Material | Polyimide, Aramid |

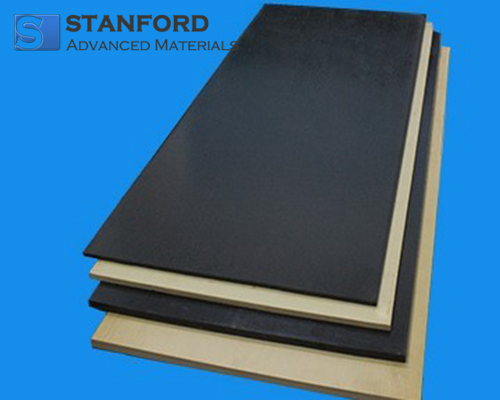

| Appearance | Golden tube |

| Thickness | 0.15/0.20mm |

Polyimide Film Aramid Nonwoven Felt Composite Sleeve is a high-performance insulating material that combines polyimide film and aramid nonwoven felt. It offers excellent thermal resistance, electrical insulation, mechanical strength, and flame retardancy, making it ideal for wire and cable protection in high-temperature and harsh environments.

Related Products: Polyimide Impregnated Glass Varnished Cloth, Polyimide Film Silicone Pressure-Sensitive Tape

Polyimide Film Aramid Nonwoven Felt Composite Sleeve Description:

Polyimide Film Aramid Nonwoven Felt Composite Sleeve is a high-performance insulating and protective material designed for demanding electrical and thermal applications. It combines polyimide film, known for its excellent heat resistance, electrical insulation, and chemical stability, with aramid nonwoven felt, which provides high mechanical strength, flexibility, and flame retardancy. This composite Sleeve offers outstanding thermal stability, abrasion resistance, and dielectric properties, making it suitable for wire and cable protection in aerospace, automotive, industrial, and high-temperature environments. Its durable and lightweight structure ensures long-term reliability in harsh operating conditions.

Polyimide Film Aramid Nonwoven Felt Composite Sleeve Specifications:

|

Material |

Polyimide, Aramid |

|

Color/Appearance |

Golden tube |

|

Thicknesses |

0.15/0.20mm |

|

Tensile Strength |

100/140MPa |

|

Bulk Resistivity |

≥1.0×10^12Ω.m |

|

Industrial Frequency Electrical Strength |

10.0/8.5KV |

|

Relative Dielectric Constant 50Hz |

3-4 |

|

Dielectric Loss Factor 50Hz |

≤5.0×10^-2 |

|

Water absorption 20±5℃ Immersion in water for 24h |

≤3% |

Polyimide Film Aramid Nonwoven Felt Composite Sleeve Applications:

1. Wire & Cable Protection: Used to insulate and protect wires, cables, and harnesses in high-temperature environments.

2. Aerospace & Defense: Applied in aircraft wiring, avionics, and military electronics due to its heat resistance, flame retardancy, and durability.

3. Automotive & Electric Vehicles (EVs): Provides thermal and electrical insulation for battery packs, wiring systems, and high-performance engines.

4. Industrial Equipment: Used in motors, generators, and electrical components that operate in extreme heat and harsh conditions.

5. High-Temperature Electrical Insulation: Applied in power transmission, transformers, and circuit protection to ensure electrical safety and stability.

Polyimide Film Aramid Nonwoven Felt Composite Sleeve Packing:

Our Polyimide Film Aramid Nonwoven Felt Composite Sleeve is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Polyimide Film Aramid Nonwoven Felt Composite Sleeve FAQ:

Q1: What is Polyimide Film Aramid Nonwoven Felt Composite Sleeve?

A1: This high-performance insulating Sleeve is made from polyimide film and aramid nonwoven felt. It offers excellent thermal resistance, electrical insulation, mechanical strength, and flame retardancy. It is ideal for wire and cable protection in high-temperature and demanding environments such as aerospace, automotive, and industrial applications.

Q2: What are the key properties of this composite Sleeve?

A2: High thermal resistance – Can withstand extreme temperatures without degrading.

Superior electrical insulation – Ensures safe and stable electrical performance.

Flame retardant – Provides excellent fire resistance for added safety.

Mechanical durability – Strong yet lightweight, offering abrasion resistance and flexibility.

Chemical & solvent resistance – Resistant to harsh chemicals, oils, and other contaminants.

Q3: What are the common applications of this Sleeve?

A3: Wire and cable protection in high-temperature environments.

Aerospace and defense – Used in aircraft wiring and avionics for insulation and durability.

Automotive and EVs – Protects wiring in battery systems, engines, and electronic components.

Industrial equipment – Used in motors, generators, and high-performance electrical systems.

Power transmission and transformers – Provides insulation for electrical safety.

Robotics and automation – Ensures protection of control systems in harsh conditions.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!