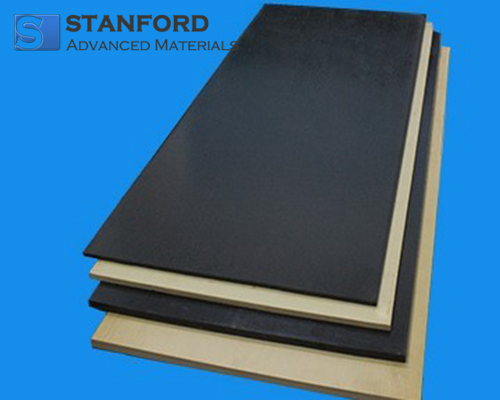

Polyimide Composite Film Description:

Polyimide Composite Film is a high-performance insulating material available in two main types: high-temperature adhesive film (FH/FHF), which is coated with F46 (polyperfluoroethylene propylene emulsion) and processed at 350°C, and low-temperature adhesive film, which is coated with modified polyester-imide and processed at 250°C. Both types exhibit excellent thermal resistance, electrical insulation, radiation resistance, and high-temperature self-sealing properties, making them ideal for use as insulation layers in wires, cables, and electromagnetic wires. These films maintain stability in extreme environments, ensuring reliability in demanding industrial applications.

Polyimide Composite Film Specifications:

|

Material

|

Polyimide

|

|

Color/Appearance

|

Transparent or translucent golden yellow film

|

|

Thicknesses

|

0.0375~0.12mm (±8%)

|

|

Width

|

8-500mm

|

|

Length

|

≥500m

|

|

Tensile strength

|

≥120MPa

|

|

Elongation at break

|

≥40%

|

|

Peel strength (bonding of fluorine to membrane)

|

≥6N/25mm

|

|

Industrial frequency electrical strength

|

≥150MV/m

|

|

Volume resistivity 200°C

|

≥1.0×10^10Ω.m

|

|

Relative dielectric constant 50Hz

|

≤3.9

|

|

Dielectric loss factor 50Hz

|

≤1.0×10^-3

|

Polyimide Composite Film Applications:

1. Electrical Insulation: Used as an insulating layer for wires, cables, and electromagnetic wires, ensuring protection in high-temperature environments.

2. Aerospace & Defense: Applied in aircraft wiring and electronic components due to its resistance to extreme temperatures and radiation.

3. Motors & Transformers: Used as an insulating material for motors, transformers, and electrical coils, enhancing durability and efficiency.

4. Flexible Printed Circuits (FPCs): Utilized in flexible circuit boards and electronics manufacturing for reliable insulation and heat resistance.

5. High-Temperature Sealing: Suitable for high-temperature self-sealing applications, ensuring strong adhesion in extreme conditions.

6. Specialized Electrical Equipment: Found in high-performance electrical and industrial equipment requiring superior insulation.

Polyimide Composite Film Packing:

Our Polyimide Composite Film is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Polyimide Composite Film FAQ:

Q1: What is Polyimide Composite Film?

A1: Polyimide Composite Film is a high-performance insulating material available in two main types:

High-temperature adhesive film (FH/FHF) – Coated with F46 (polyperfluoroethylene propylene emulsion) and processed at 350°C.

Low-temperature adhesive film – Coated with modified polyester-imide adhesive and processed at 250°C.

Both types offer excellent thermal resistance, electrical insulation, radiation resistance, and self-sealing properties, making them ideal for insulation applications in wires, cables, and electromagnetic wires.

Q2: What are the key properties of Polyimide Composite Film?

A2: High thermal stability – Can withstand temperatures up to 350°C (FH/FHF) and 250°C (low-temperature type).

Excellent electrical insulation – Provides superior insulation for electrical and electronic applications.

Radiation resistance – Ideal for aerospace, defense, and nuclear applications.

Self-sealing at high temperatures – Ensures strong adhesion during use.

Durability and chemical resistance – Resistant to harsh environments, ensuring long-term performance.

Q3: What are the common applications of Polyimide Composite Film?

A3: Electrical insulation for wires, cables, and electromagnetic wires.

Motors and transformers insulation to improve efficiency and lifespan.

Flexible printed circuits (FPCs) in electronic devices.

Aerospace and defense applications due to its high-temperature and radiation resistance.

High-temperature sealing applications requiring strong adhesion and durability.