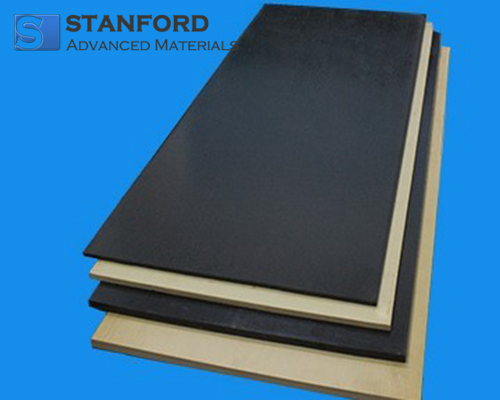

Polyimide Film (PI Film) Description

Polyimide Film (PI Film) is a high-performance material known for its exceptional properties, including outstanding electrical insulation, mechanical strength, and chemical stability. It has excellent thermal stability, maintaining its integrity over a wide temperature range from -269 °C to 400°C, making it ideal for high-temperature applications. PI Film also exhibits superior radiation resistance, flame retardancy (UL-94 rated), and low dielectric loss, which makes it suitable for demanding environments. Additionally, it has enhanced adhesion properties due to a unique surface treatment, offering excellent bonding capabilities for various composite applications. These features make it an essential material in industries such as electronics, aerospace, and automotive.

Polyimide Film (PI Film) Specifications:

|

Material

|

Polyimide

|

|

Color/Appearance

|

Transparent or translucent golden yellow film

|

|

Density

|

1420±20 kg/m3

|

|

Thicknesses

|

0.02mm-0.20mm

|

|

Tensile strength Longitudinal and transverse

|

≥135MPa

|

|

Elongation at break Longitudinal and transverse

|

≥45%

|

|

Surface resistivity 200℃

|

≥1.0×1013Ω

|

|

Volume resistivity 200℃

|

≥1.0×1010Ω.m

|

|

Relative dielectric constant 50Hz

|

3.5±0.4

|

|

Dielectric loss factor 50Hz

|

≤1.0×10-3

|

|

Shrinkage rate 150℃

|

≤1.0%

|

|

Long-term heat resistance temperature index

|

≥220

|

Polyimide Film (PI Film) Applications:

1. Electrical Insulation: Used in motors, electrical cables, and high-temperature wiring for electrical insulation in various industries.

2. Aerospace & Automotive: Ideal for aerospace components and automotive electronics due to its thermal stability and resistance to radiation and extreme environments.

3. Flexible Printed Circuit Boards (FPCBs): A key material in flexible printed circuit boards used in electronics, enabling high-performance, space-saving designs.

4. Nuclear Power Equipment: Used in nuclear power plants for equipment requiring high temperature and radiation resistance.

5. Specialty Electrical Equipment: Found in specialized electrical appliances, such as high-temperature electrical components, fireproof bus ducts, and safety equipment like gas masks.

6. Speaker Components: Used in speaker voice coil structures due to its mechanical strength and flexibility.

7. Insulation for High-Temperature Cables: Suitable for use in high-temperature cables that need to maintain performance under extreme conditions.

Polyimide Film (PI Film) Packing:

Our Polyimide Film (PI Film) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Polyimide Film (PI Film) FAQ:

Q1: What is Polyimide Film (PI Film)?

A1: Polyimide Film (PI Film) is a high-performance polymer film known for its excellent electrical insulation, mechanical strength, thermal stability, radiation resistance, and flame retardancy. It is used in various demanding applications such as motors, electrical cables, flexible printed circuit boards (FPCBs), and high-temperature components.

Q2: What are the key properties of Polyimide Film?

A2:

- Electrical Insulation – Provides outstanding insulation for electronic devices and electrical components.

- Thermal Stability – Can withstand temperatures ranging from -269°C to 400°C without significant degradation.

- Radiation Resistance – Excellent resistance to radiation, making it ideal for use in aerospace and nuclear applications.

- Flame Retardancy – Rated UL-94 for its flame-retardant properties, suitable for high-risk environments.

- Low Dielectric Loss – Suitable for applications requiring minimal signal loss.

- Enhanced Adhesion – Features a unique surface treatment to improve bonding and adhesion in composite materials.

Q3: What are the common applications of Polyimide Film?

A3: Polyimide Film is widely used in:

- Motors and electrical cables for high-temperature insulation.

- Aerospace and automotive components.

- Flexible printed circuit boards (FPCBs) in electronics.

- Nuclear power equipment and specialized electrical appliances.

- Speaker components and other high-performance electronics.