- Products

- Categories

- Blog

- Podcast

- Application

- Document

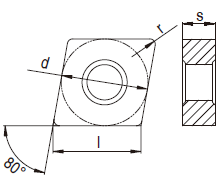

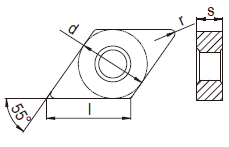

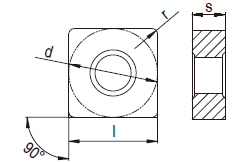

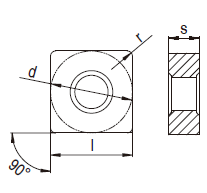

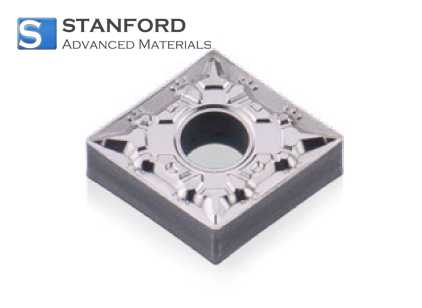

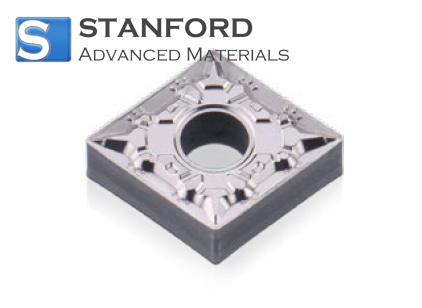

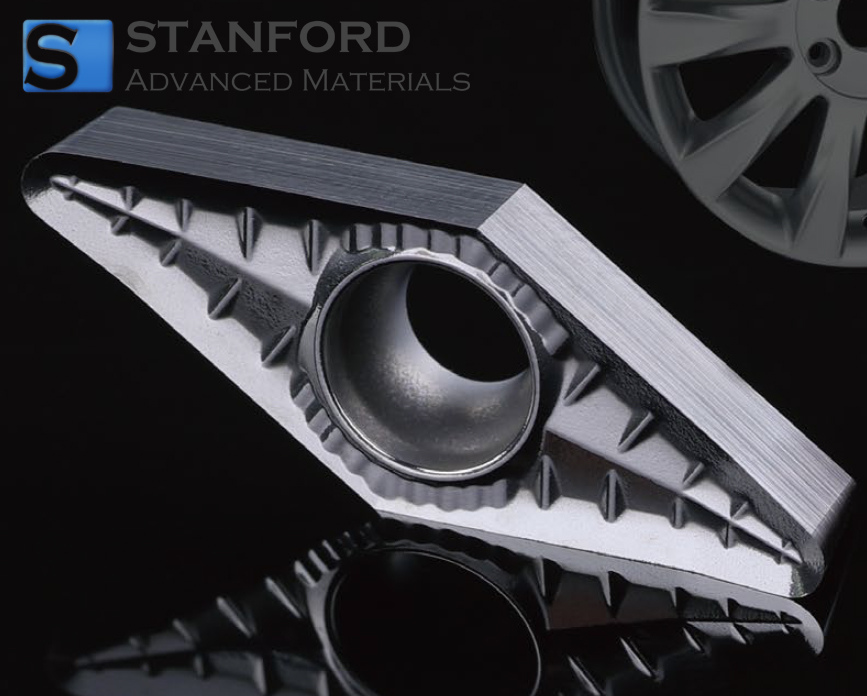

CUT3203 AP100S Turning Insert (Negative Insert)

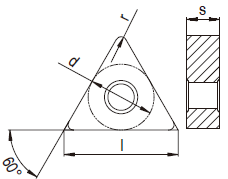

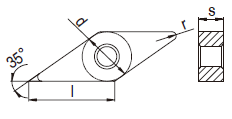

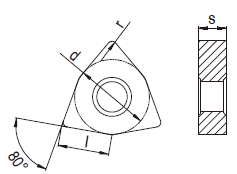

| Catalog No. | CUT3203 |

| Type | Negative insert |

| Coating Material | PVD |

| Chip Breaker | MB2, SC3, MC4 |

AP100S Turning Insert (Negative Insert) provides excellent machining performance on superalloys and stainless steels. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality cutting tools.

Related products: PCBN Turning Inserts, PCD Turning Inserts, AP100S Turning Insert (Positive Insert)

INQUIRY

Add to Inquiry List

Description

Specification

LATEST RECOMMENDED

CUT3146 Cermet Insert-AT200 (NEGATIVE M-CLASS INSERT)

CUT3147 Cermet Insert-AT200 (Positive M-class insert)

CUT3173 Cermet Insert-AT200 (Negative G-class insert)

CUT3174 Cermet Insert-AT200 (Positive G-class insert)

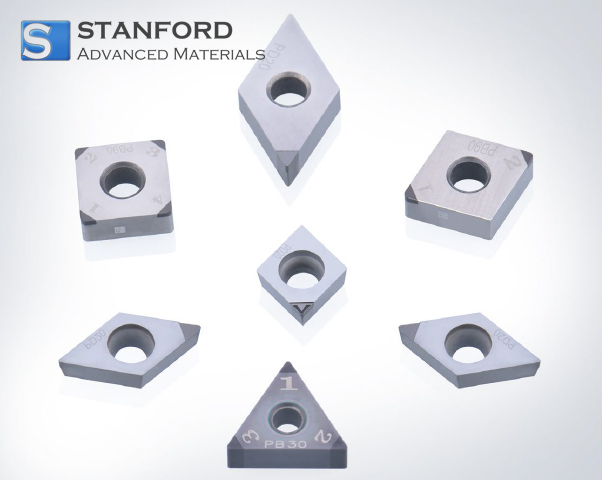

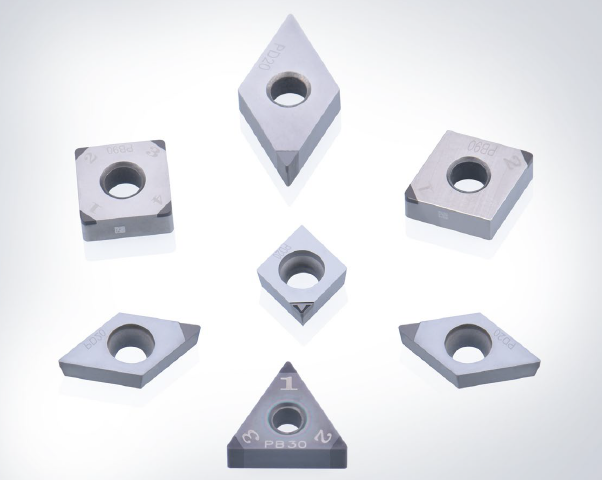

CUT3178 PCBN Turning Inserts

CUT3179 PCD Turning Inserts

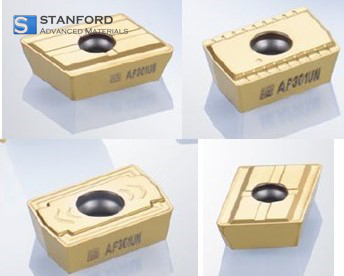

CUT3180 Deep-hole Drilling Inserts

CUT3181 Uncoated Turning Insert for Non-ferrous Material AW100K

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!