- Products

- Categories

- Blog

- Podcast

- Application

- Document

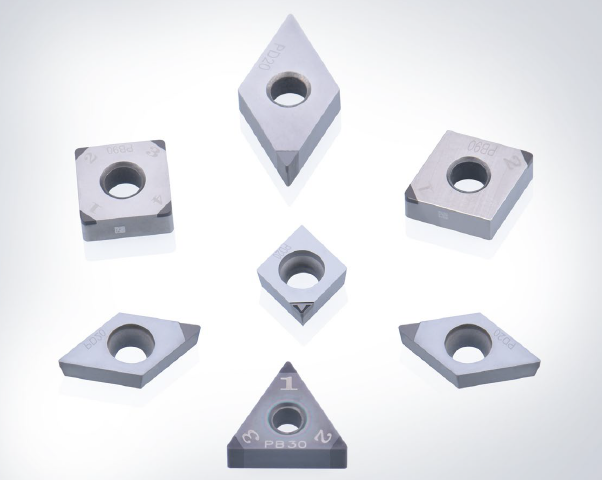

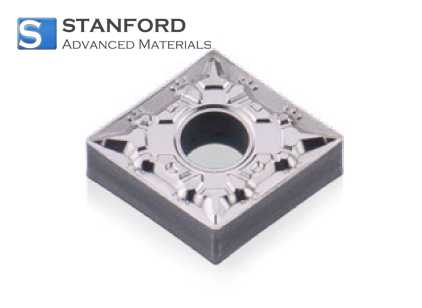

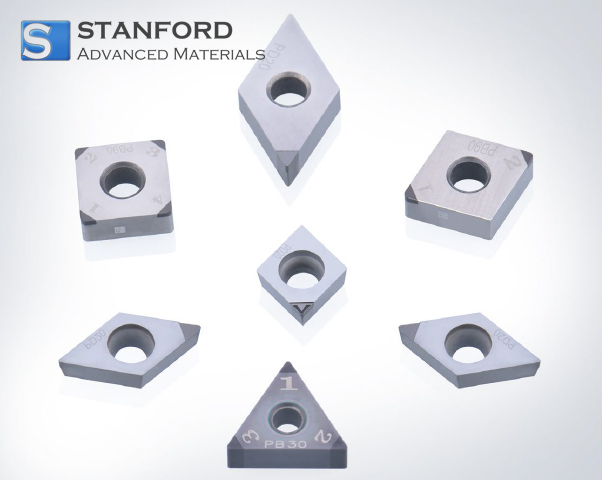

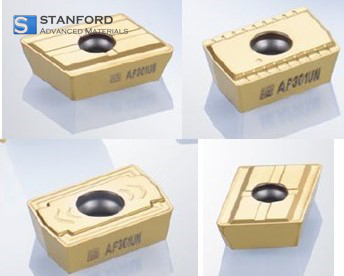

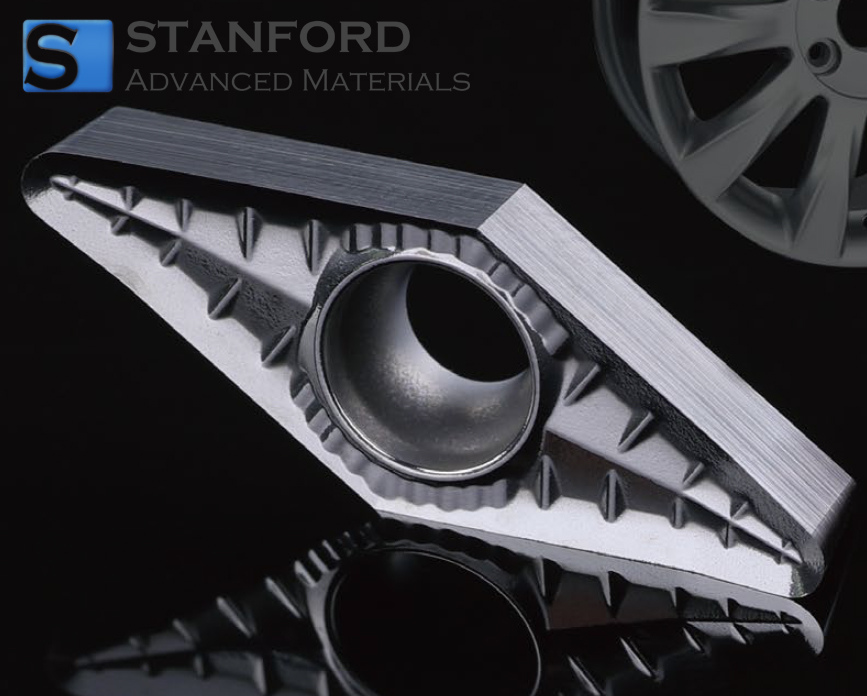

CUT3179 PCD Turning Inserts

| Catalog No. | CUT3179 |

| Grade | PD01, PD10, PD20 |

| Type | Negative 80°(CN), 55°(DN), 60°(TN), 35°(VN); Posi |

PCD Turning Inserts is an ideal solution for machining aluminum alloy and high-hardness materials. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Cutting Tools.

Related products: PCBN Turning Inserts, Cermet Insert-AT200 (NEGATIVE M-CLASS INSERT), Cermet Insert-AT200 (Positive M-class insert)

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!